Vertical type combined air processor

An air handler and combined technology, applied in heating methods, air-conditioning systems, mechanical equipment, etc., can solve the problems of filter shutdown and cleaning, inconvenient, etc., to achieve a completely dense corrosion-resistant layer, multiple functions, heat-resistant cycles and shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

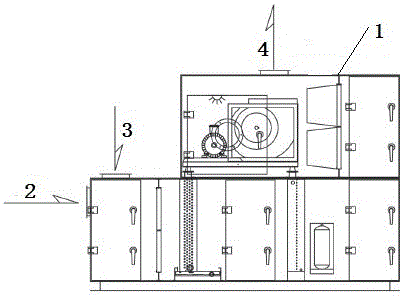

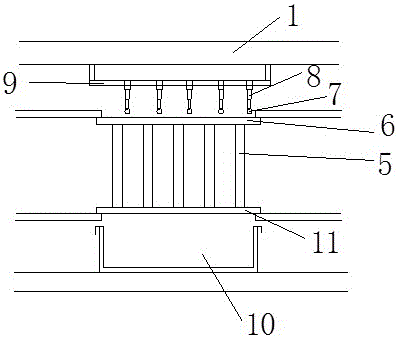

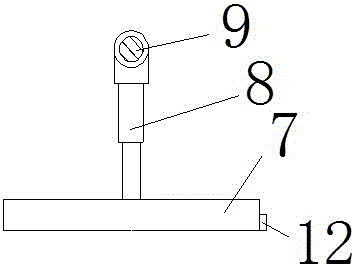

[0017] As shown in the figure, the vertical combined air handler of the present invention includes an external box body 1, and the external box body 1 is arranged in upper and lower layers, and an air return port 2 and a fresh air port 3 are arranged at one end of the lower layer of the external box body 1 , the upper layer of the external box 1 is provided with an air outlet 4, and the lower layer of the external box 1 is also provided with a mixing section, an initial filter section, a cooling coil section, an inspection section, a heating coil section, a humidification section, an ozone section and a disinfection section. For the sound section, the upper layer of the external box 1 is provided with a fan section, a flow equalization section, a medium-efficiency filter section, and an air outlet section, and an empty section is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com