Energy-saving waste water recycling and hot water constant-temperature supplying system

A technology of supply system and waste water recovery, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of easily damaged water meters, insufficient waste heat conversion, unreasonable structure, etc. Simple and good market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

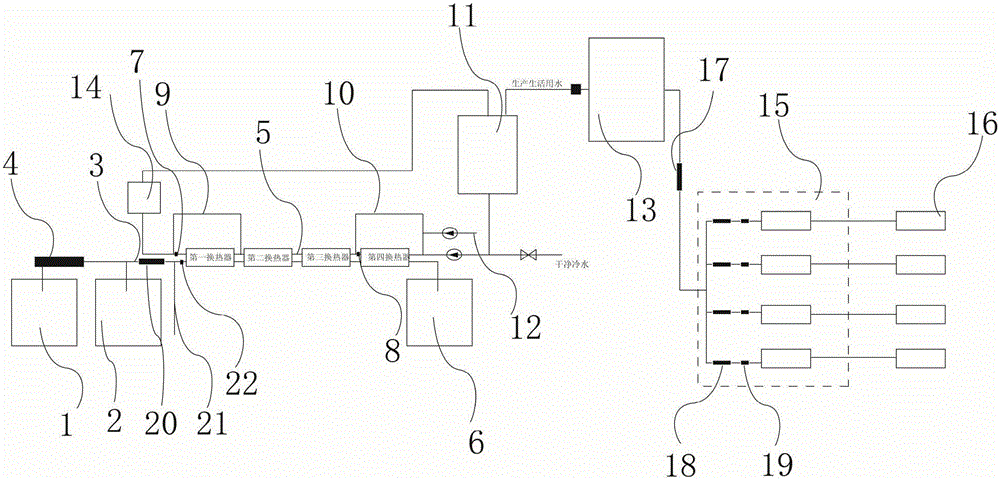

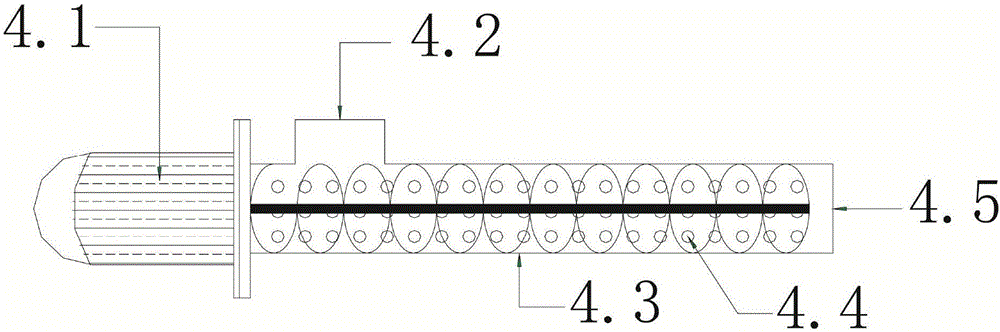

[0031] Such as figure 1 , Is a schematic diagram of the overall structure of the present invention, including the sewage tank 2, the sewage tank 2 is connected with the sewage pipe 3, the sewage pipe 3 is provided with a slag discharge device 4, the slag discharge device 4 includes a shell 4.3, on the shell 4.3 is provided Sewage inlet 4.2 and sewage hole 4.4. Sewage enters the housing 4.3 through the sewage inlet 4.2, and discharges the debris through the rotating mechanism in the housing 4.3 (driven by the motor 4.1), and the sewage continues in the sewage pipe through the sewage hole 4.4 3 flow, the system includes the first heat exchanger, the second heat exchanger, the third heat exchanger and the fourth heat exchanger, which are arranged in order from left to right. In the above heat exchanger, the sewage pipe 3 Connected to the heat exchanger in turn from left to right; on the right side is provided with a cold water pipe 5, which is connected to the heat exchanger in tur...

Embodiment 2

[0041] The difference from Embodiment 1 is that the first heat exchanger is provided with a water supplement pipe, and the remaining working modes and principles are the same as Embodiment 1.

Embodiment 3

[0043] Different from Example 1, when the system is installed in a school, the dormitory is vertical for each unit, and the water meters of each dormitory in the unit are collectively set in a box, and each water meter is connected to the card reader separately through a wire. The placement avoids the problem that students can destroy the water meter in the dormitory and abuse hot water at will. The structure is simple and convenient, and the setting of the water meter and the card reader can be realized according to the existing technology, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com