Control method of blasting block size for inert medium spacer charge at hole bottom

A technology of inert medium and interval charging, applied in blasting and other directions, can solve the problems of unproposed blasting lumpiness, unfavorable construction, control method, etc., and achieve the effect of improving blasting effect, improving flatness, and prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

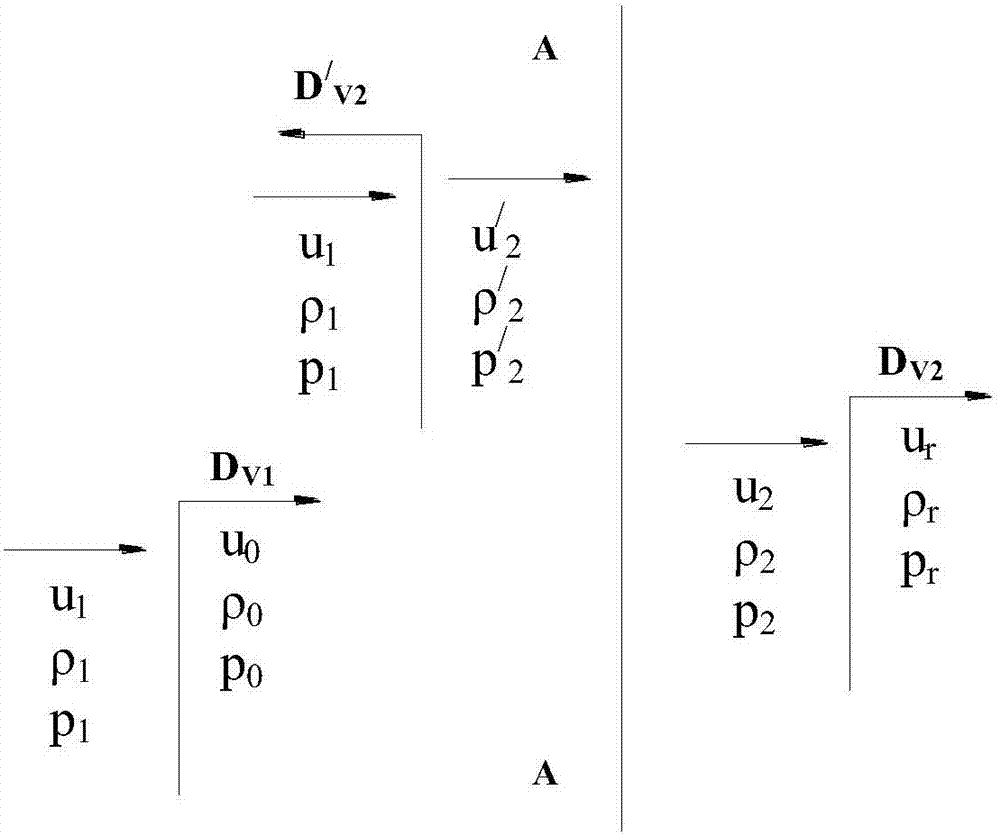

[0043] In the application of inert medium spacer charge for rock blasting engineering, inert medium such as air and water are often sealed in the spacer to optimize the blasting parameters. Such as figure 1 As shown, when the charge is coupled, the detonation wave propagates from left to right in the explosive, and when it reaches the interface of the explosive rock, transmission and reflection occur. Spread left.

[0044] Let the initial parameters of the explosive be: p 0 , ρ 0 , u 0 =0; detonation wave velocity is D V1 , the initial parameter of the detonation wave is the detonation product: p 1 , ρ 1 , u 1 ; The initial parameters of the rock are: p r , ρ r , u r =0, the velocity of elastic wave in the rock is C P ;The reflected wave parameter is: p' 2 , ρ' 2 , u' 2 , the wave velocity is D' V2 ; The transmitted wave parameter is: p 2 , ρ 2 , u 2 , the wave speed is D V2 . There is a continuous condition p' at the interface between explosives and rocks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com