A gas collection method for internal gas analysis of lithium-ion batteries

A lithium-ion battery and gas technology, applied in the analysis of materials, sampling, instruments, etc., can solve the problems of external impurity gas mixing, achieve convenient analysis, convenient collection, and realize the effect of gas production composition and mechanism analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, and the following examples are only to illustrate the present invention rather than limit it.

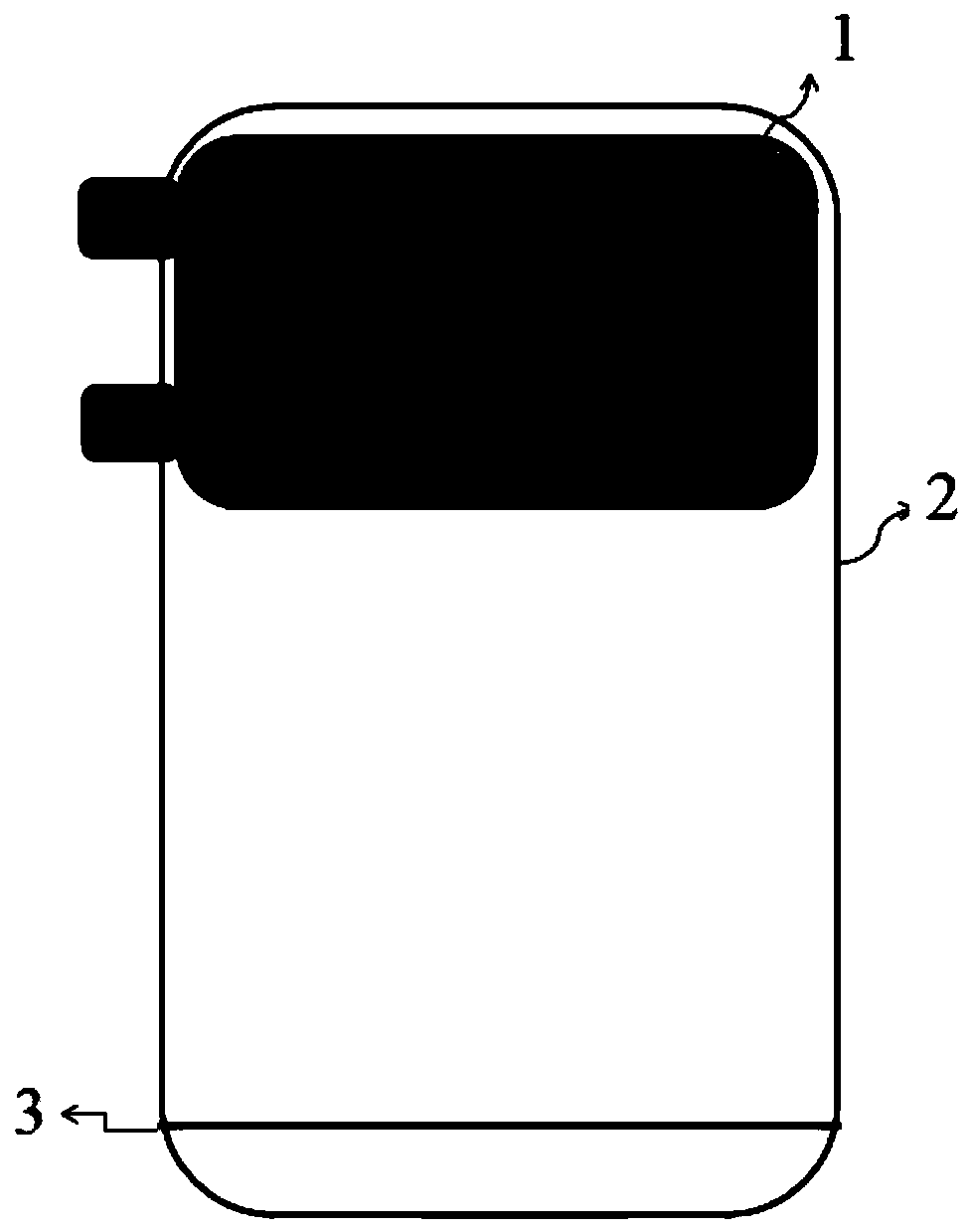

[0015] Step 1: Seal the inner core 1 of the lithium-ion battery to be analyzed with an aluminum-plastic film 2 soft package.

[0016] Step 2. After the sealing is completed, bake the battery, inject liquid, and perform the first packaging along the first packaging line (such as figure 1 ), the package is completed and put on hold.

[0017] Step 3. After putting aside for a certain period of time, carry out tests on the battery for formation, capacity separation, heating, overcharging, overdischarging or other possible gas production.

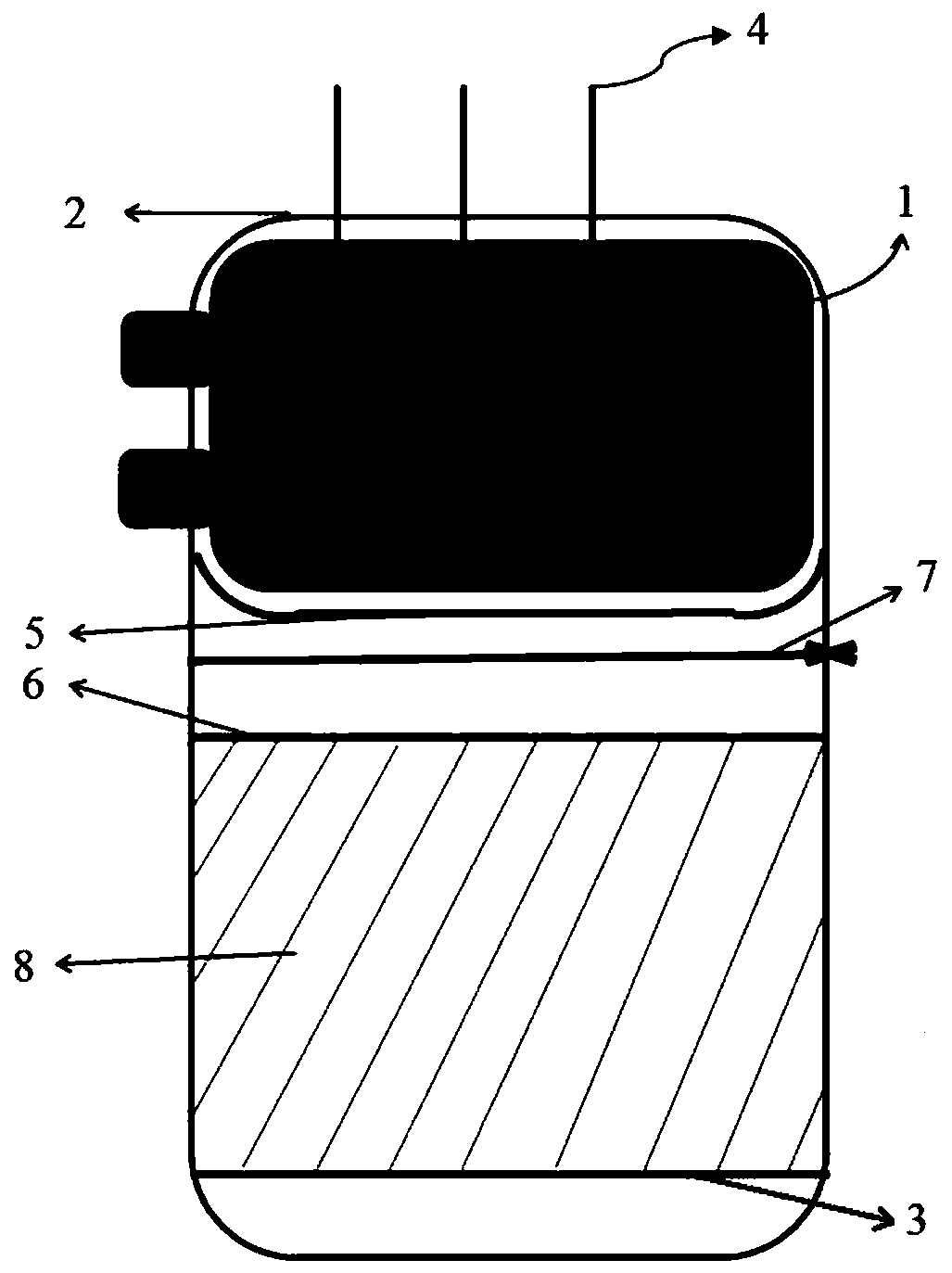

[0018] Step 4. Select the stage to be analyzed and tested. Clamp the aluminum-plastic film 2 with the external pressure 4 and then perform secondary packaging along the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com