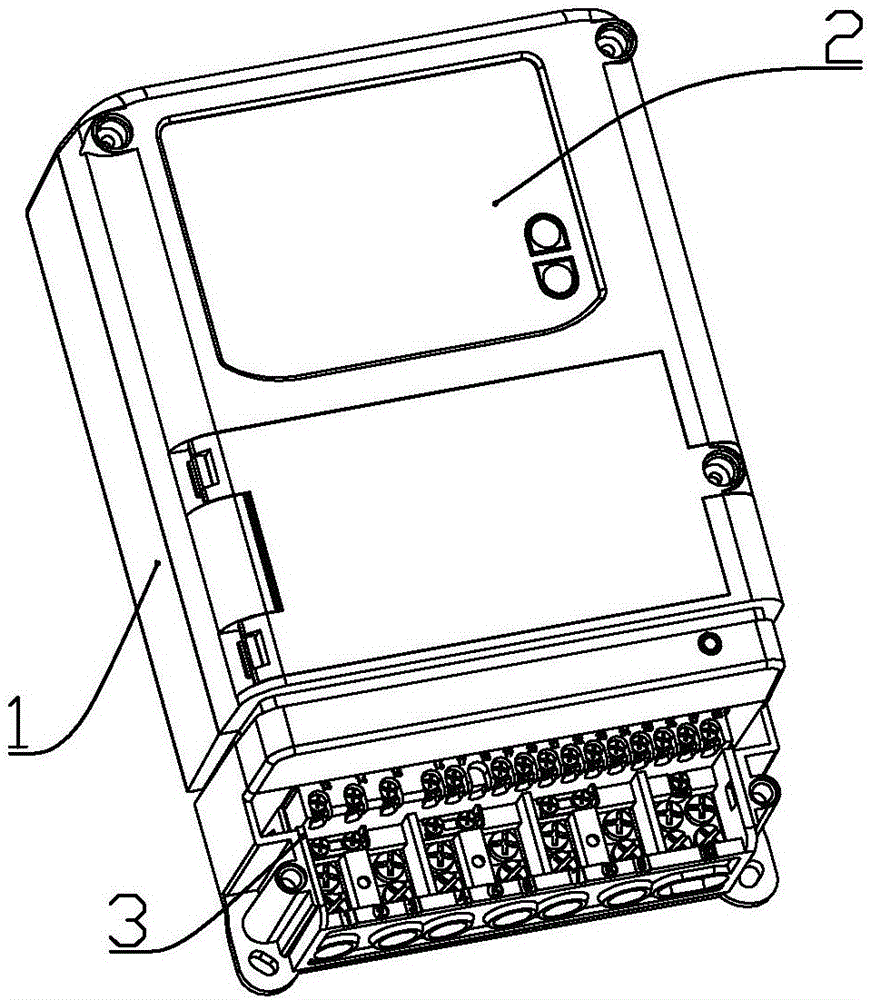

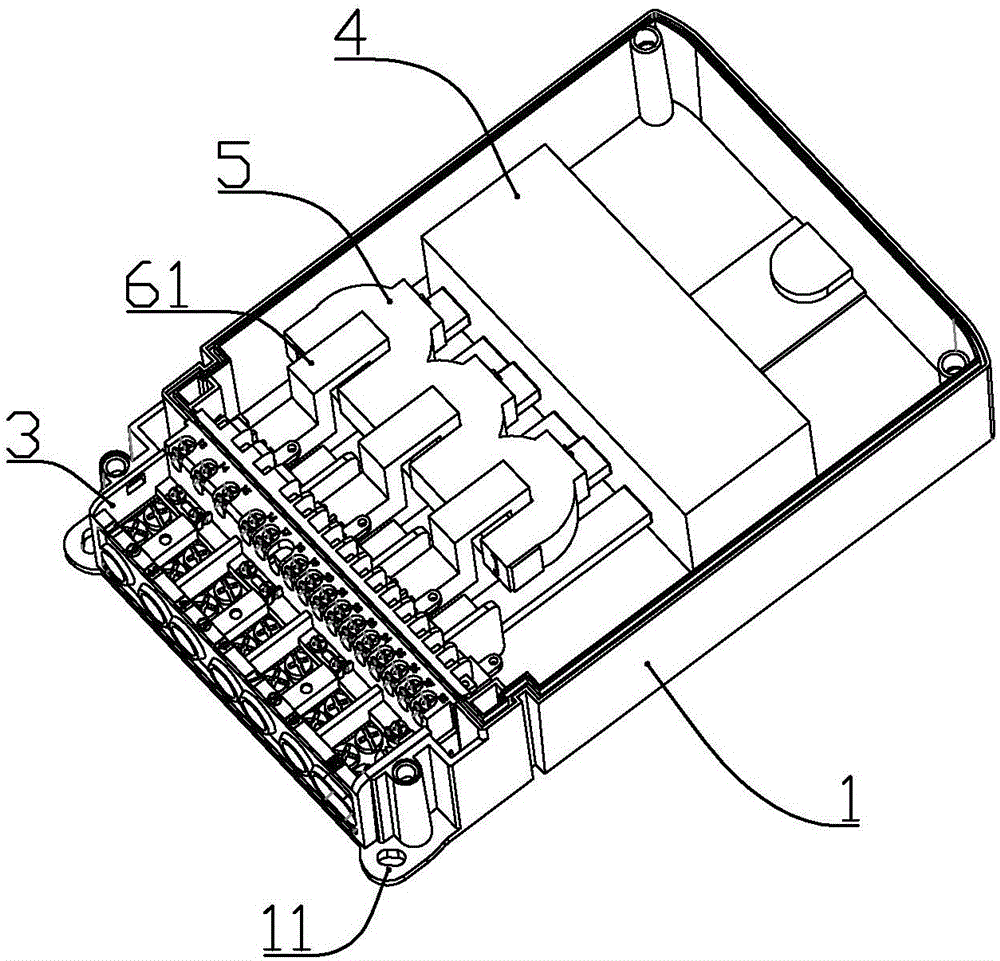

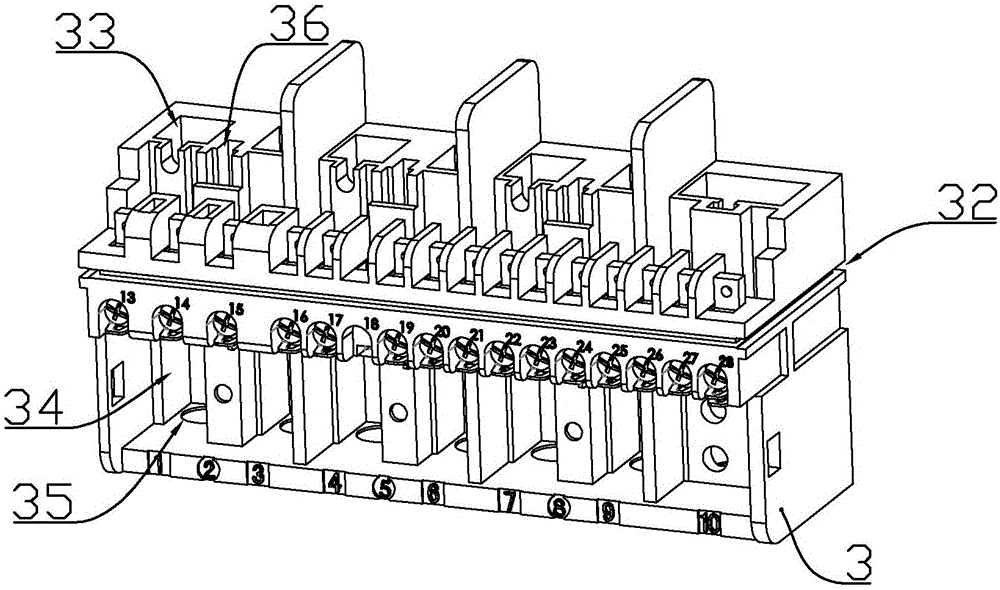

Three-phase electric meter

A three-phase electric meter and current terminal technology, applied in the electric power field, can solve the problems of shortening the service life of the smart electric meter, affecting the service life of the electric energy meter, large heat generation in the wiring slot, etc. Ensure the effect of normal sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0074] combine Figure 16 and Figure 17 , this embodiment makes the following improvements on the basis of Embodiment 1: the locking screw b69 is formed with an internally threaded hole in the axial direction, and the internally threaded hole is a tapered hole with a wide front and a narrow rear. The thread is a left-handed thread, and the thread on the outer wall of the locking screw b is a right-handed thread; the locking screw b is provided with 4 strip-shaped gaps equidistant along the circumference, and the strip-shaped gaps extend from the bottom of the nut of the locking screw b To the front end of the locking screw b; the internal thread of the internal threaded hole is connected with a tapered screw 691 with a wide front and a narrow rear, and the outer wall of the tapered screw is correspondingly formed with a left-handed thread.

[0075] The tapered screw is pre-connected to the locking screw b. When in use, connect the locking screw b to the screw hole a. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com