Touch display substrate and manufacturing method thereof and touch display device

A technology for a touch display substrate and a manufacturing method is applied in the fields of a touch display device, a touch display substrate and a manufacturing method thereof, and can solve the problems of affecting the layout of data lines, poor picture display quality, unbalanced brightness of the display picture, etc. Improve the display effect, enhance the picture display quality, and ensure the effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

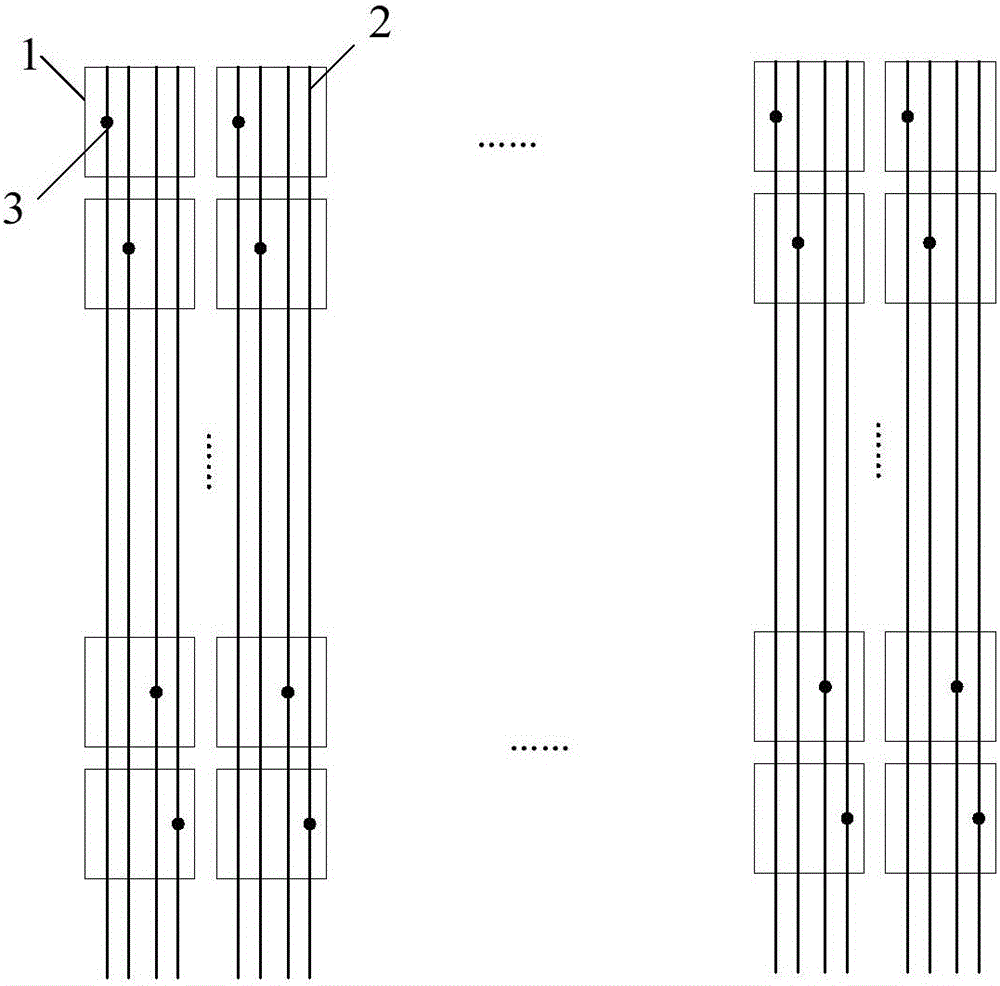

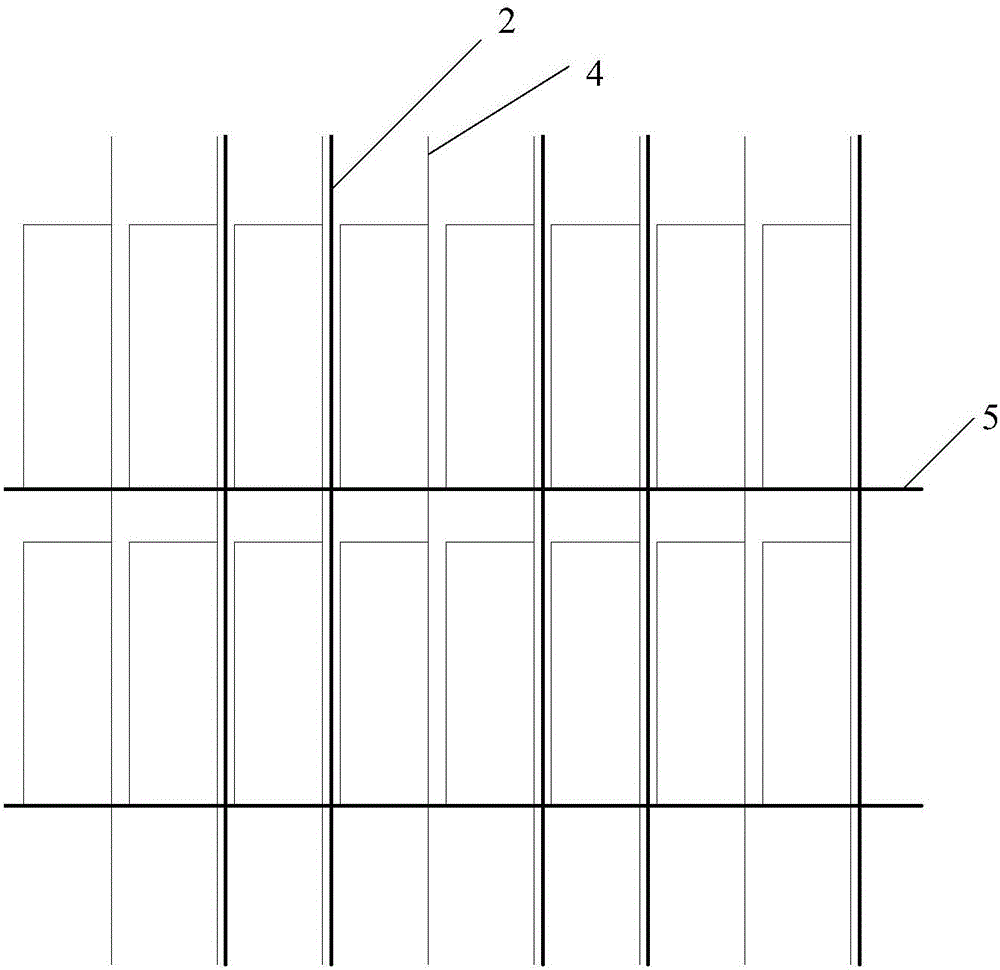

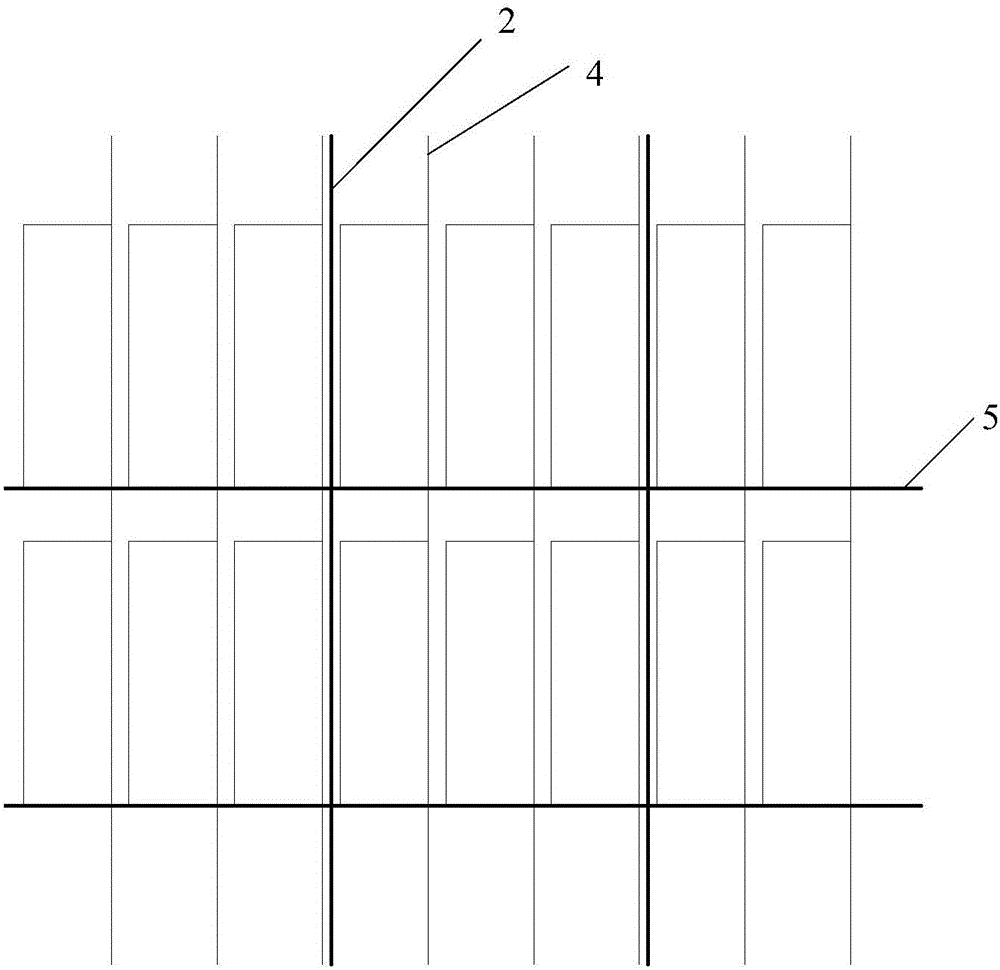

[0038] This embodiment provides a touch display substrate, including a plurality of gate lines and a plurality of data lines arranged crosswise on the base substrate, and the touch display substrate also includes a plurality of touch electrodes and a plurality of touch signals lines, the touch electrodes are used to load common electrode signals and touch scan signals in a time-division manner, each of the touch electrodes is electrically connected to at least one of the touch signal lines, and the touch signal lines are connected to the grid lines parallel.

[0039] In this embodiment, the touch signal line is parallel to the gate line, so that the arrangement of the touch signal line will not affect the layout of the data lines, and the parasitic capacitance between the pixel electrode of the sub-pixel and the adjacent two data lines can be equal. In this way, when the touch display device is working, two adjacent data lines have the same influence on the pixel electrodes of...

Embodiment 2

[0047] This embodiment also provides a touch display device, including the above-mentioned touch display substrate, and also includes a touch chip, each of the touch electrodes is connected to the touch chip through a corresponding touch signal line The touch signal line transmits the touch scanning signal to the touch electrode during the touch stage, and transmits the touch signal generated by the touch electrode at the position where the touch occurs to the touch chip.

[0048] In a specific embodiment, the touch control chip is multiplexed as the gate drive chip of the touch display device, so that one chip can realize the touch control function and output the scanning signal at the same time without increasing the number of chips.

Embodiment 3

[0050] This embodiment provides a method for manufacturing a touch display substrate. The touch display substrate includes a plurality of gate lines and a plurality of data lines arranged crosswise on the base substrate. The touch display substrate further includes a plurality of a touch electrode, the touch electrode is used to time-divisionally load the common electrode signal and the touch scan signal, and the manufacturing method includes:

[0051] A plurality of touch signal lines parallel to the gate lines are formed, and each of the touch electrodes is electrically connected to at least one of the touch signal lines.

[0052] In this embodiment, the touch signal lines are made parallel to the gate lines, so that the arrangement of the touch signal lines will not affect the layout of the data lines, and the parasitic connection between the pixel electrode of the sub-pixel and two adjacent data lines can be reduced. The capacitances are equal, so that when the touch displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com