Virtual monitoring system and method for digital mine

A monitoring system and digital mine technology, applied in the field of 3D modeling, can solve problems such as large amount of model data, lack of data-driven 3D model visualization for mine production management, and inability to apply computer system performance across platforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

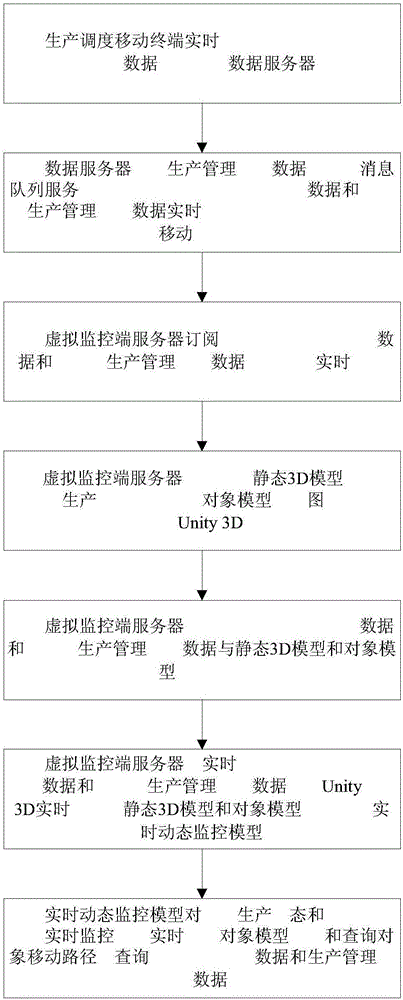

[0032] The invention proposes a digital mine-oriented virtual monitoring system and method, and solves the efficient broadcast subscription method of various production management data in the mine. Realize the real-time mine production management data obtained from the data server system, and realize the data-driven dynamic 3D model and scene of the entire mine on the basis of the static 3D model of the mine. A realization method and approach of monitoring and 3D visualization management have good application prospects.

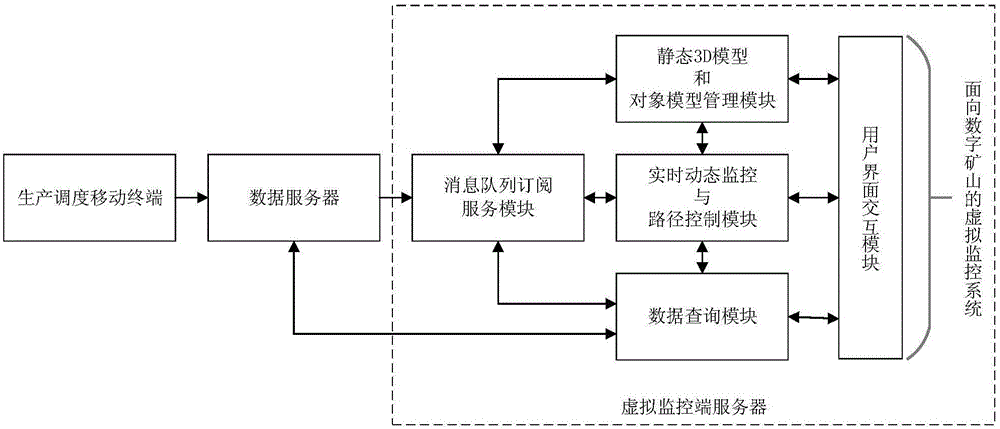

[0033] A virtual monitoring system for digital mines, such as figure 1 As shown, it includes production scheduling mobile terminal, data server, and virtual monitoring server.

[0034] The production scheduling mobile terminal communicates with the data server through the wireless local area network or mobile Internet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com