RFID-based single-layer warehouse forklift positioning system

A positioning system, a technology for leveling forklifts, applied in the field of positioning systems for storage, logistics and transportation equipment, can solve the problems of limited positioning accuracy, difficult to meet, limited reading distance, etc., to avoid difficulties in routing, reduce equipment costs, and implement handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

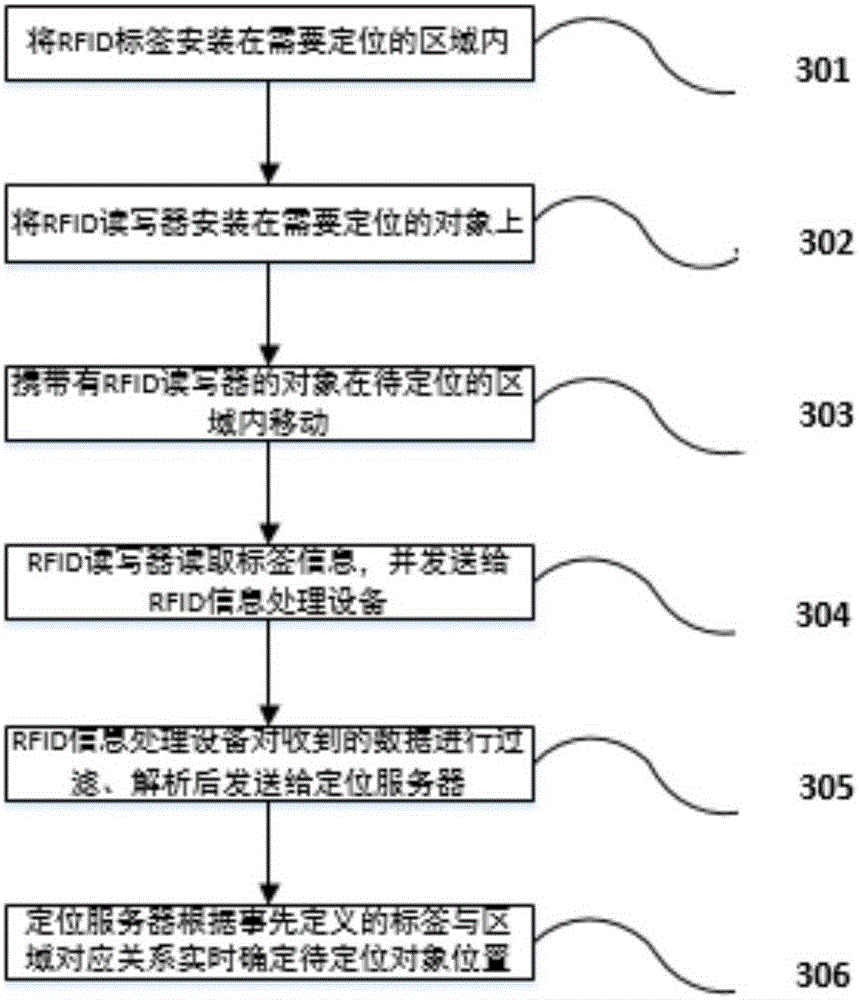

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

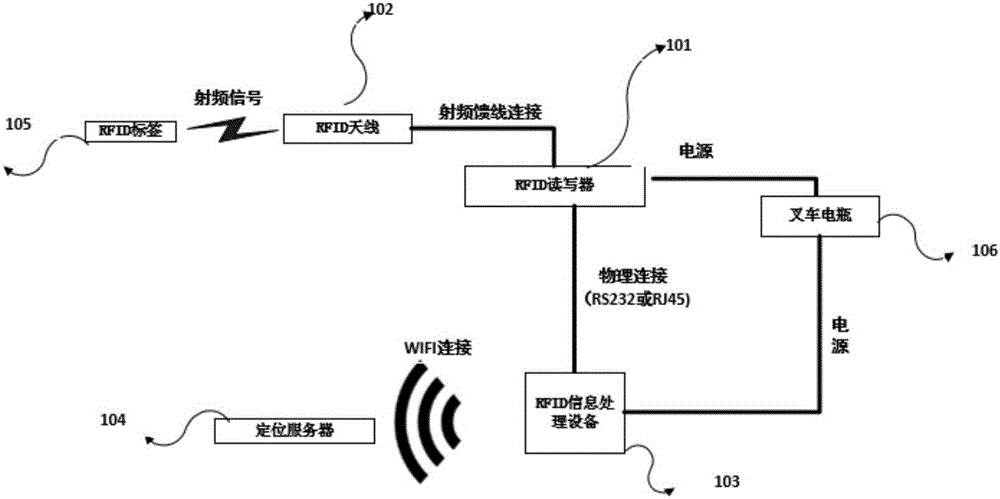

[0025] An RFID-based Pingku forklift positioning system is characterized in that it is sequentially connected by an RFID electronic tag, an RFID antenna, an RFID reader, an RFID information processing device, and a positioning server.

[0026] In the present invention, at least one RFID electronic tag communicates with the RFID reader through a radio frequency signal. The RFID antenna is connected with the RFID reader through a radio frequency feeder. The network is connected to the location server.

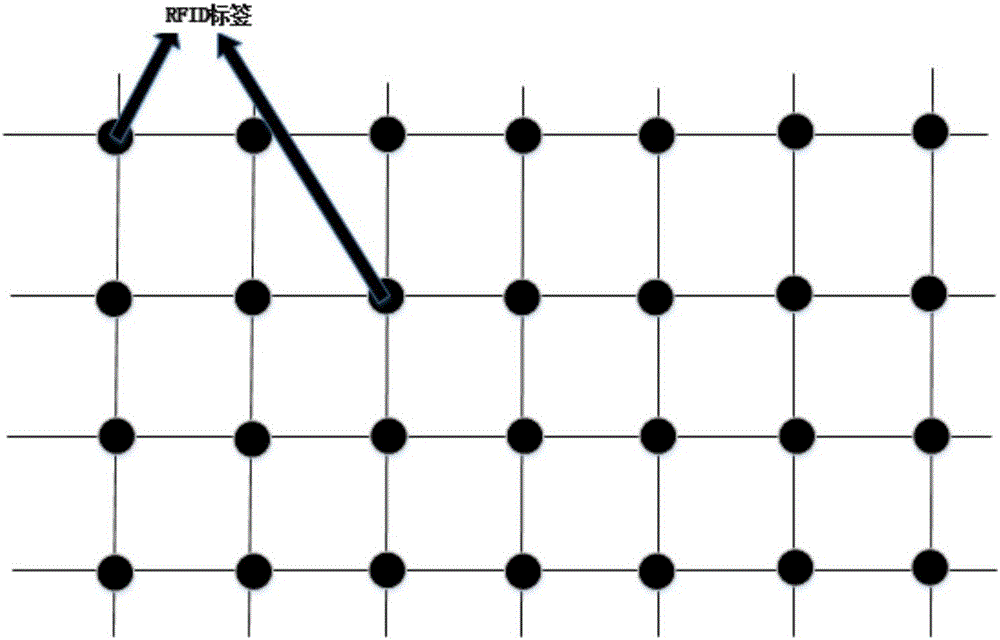

[0027] The RFID electronic tag described in the present invention is arranged above the cargo position to be positioned;

[0028] The RFID reader, RFID antenna, and RFID information processing equipment are installed on a forklift, and the RFID reader reads the data information of the RFID tag, and transmits the R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com