Temporary bonding processing method of sheet workpiece

A processing method and a sheet-like technology, applied in the field of microelectronics, can solve the problems of high equipment cost, complex wafer processing procedures, and high processing cost, and achieve a simple process, simple and fast processing method, and low equipment cost and processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

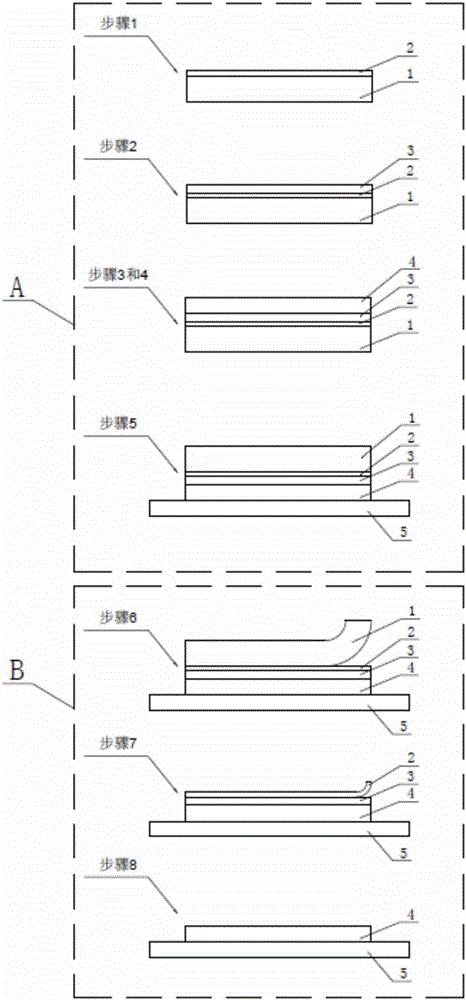

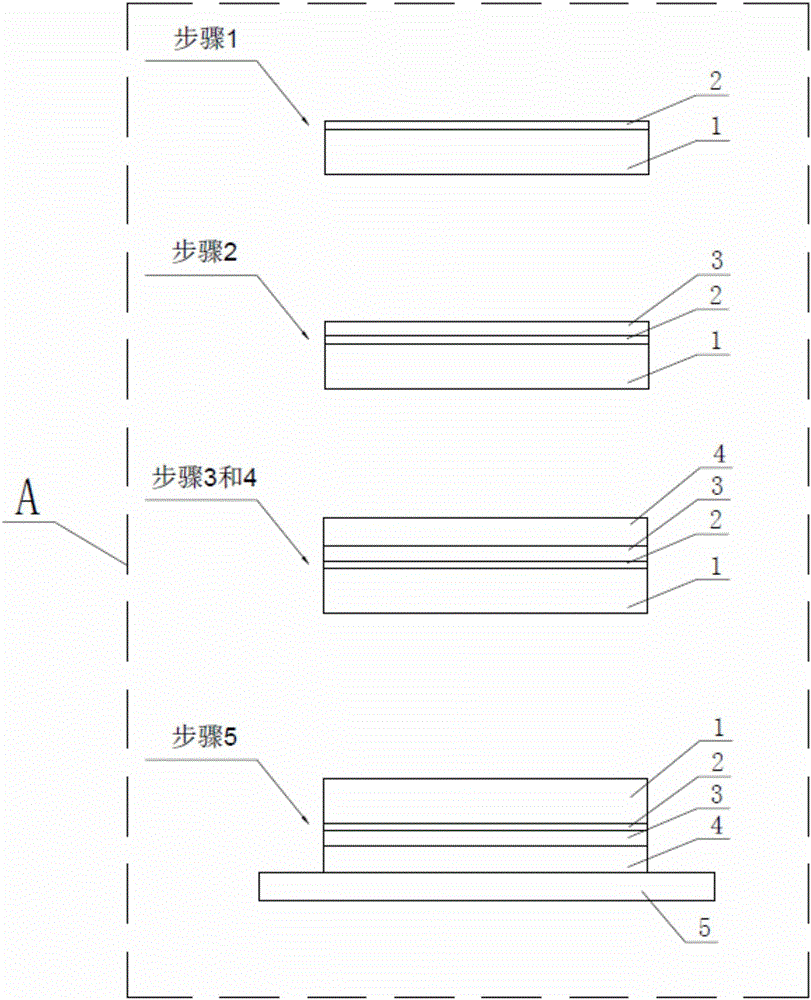

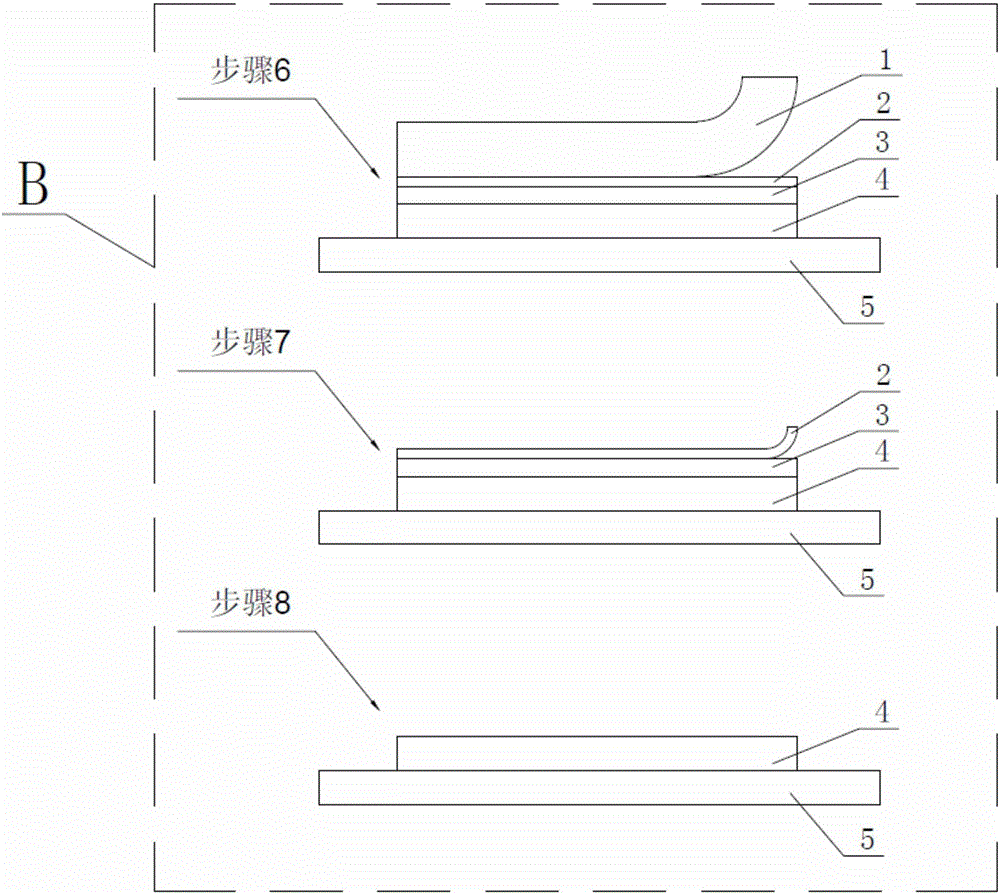

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] The above-mentioned flaky workpiece generally refers to the processing of wafers, of course, it can also be applied to high-precision processing of other sheet products such as glass.

[0027] The invention provides a processing method for temporary bonding of sheet-shaped workpieces, which is characterized in that it comprises the following steps:

[0028] Step 1. Select a carrier plate 1, and set an isolation film 2 on the front of the carrier plate 1. The carrier plate 1 is made of a bendable material; the isolation film 2 is prepared on the carrier plate by spin coating or spray coating. on the front side of board 1.

[0029] Step 2, coating a layer of bonding glue 3 on the isolation film 2; the bonding glue 3 can be selected from commercially available chemical bonding materials, which can be dry bonding or wet bonding materials. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com