Modified fiber fabric and preparation method thereof

A fabric and modification technology, applied in the field of modified fiber fabric and its preparation, can solve the problems of high cost, high biological toxicity, poor oleophobic performance, etc., and achieve easy operation, good performance, and increase of active reactive groups. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

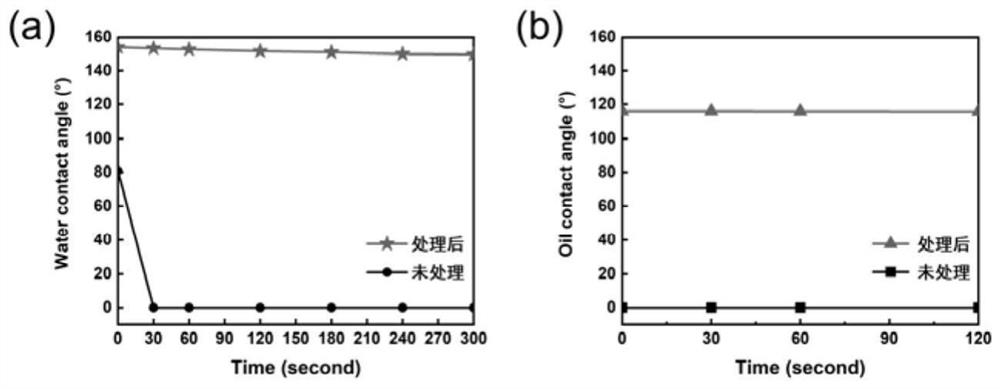

[0031] The dirt-resistant and antistatic dirt-resistant treatment method of nylon fiber fabric modification treatment method comprises the following steps:

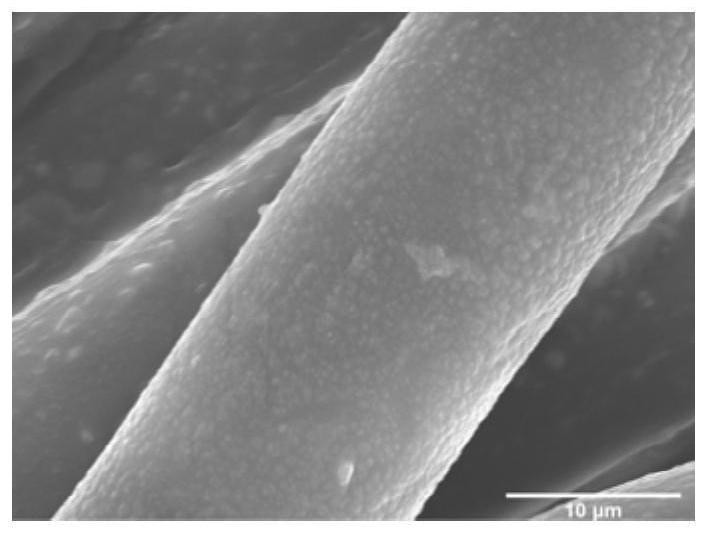

[0032] (1) Nylon fiber fabrics need to be soaked in deionized water, ethanol, acetone and n-hexane in order to be fully cleaned before modification, and then dried for use. Subsequently, the pre-dried nylon fiber fabric sample is placed in a plasma processor, and the power is adjusted to 300W, so that the nylon fiber fabric is treated for 2 minutes on each side under an oxygen atmosphere to obtain a hydrophilic nylon fiber fabric;

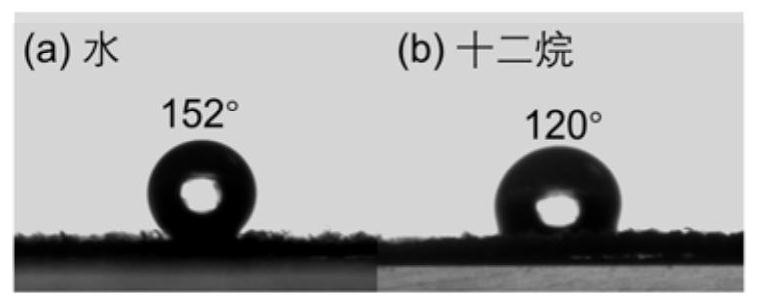

[0033] (2) Add 10ml of ethanol, 0.1g of ferric chloride, 1ml of 1H,1H,2H,2H-perfluorooctyltriethoxysilane into the weighing bottle, stir well, then add the nylon treated in step (1) Immerse the fiber fabric for 2 minutes, take it out and dry it at room temperature for 1 hour;

[0034] (3) Put the nylon fiber fabric treated in step (2) into a closed chamber filled with nitrogen, add 1ml of ani...

Embodiment 2

[0040] The dirt-resistant and antistatic dirt-resistant treatment method of nylon fiber fabric modification treatment method comprises the following steps:

[0041] (1) Nylon fiber fabrics need to be soaked in deionized water, ethanol, acetone and n-hexane in order to be fully cleaned before modification, and then dried for use. Then, place the pre-dried nylon sample in a plasma processor, adjust the power to 300W, and treat the nylon fiber fabric for 5 minutes on each side under an oxygen atmosphere to obtain a hydrophilic nylon fiber fabric;

[0042] (2) Add 15ml of ethanol, 0.2g of ferric chloride, 1.5ml of 1H, 1H, 2H, 2H-perfluorooctyl trichlorosilane into the weighing bottle, stir well, then add the nylon fabric NF in step (1) Immerse for 5 minutes, take out and dry at room temperature for 2 hours;

[0043] (3) Put the nylon fiber fabric treated in step (2) into a closed chamber filled with nitrogen, add 1ml of aniline and 1ml of pyrrole, heat and react at 70°C for 14h, ...

Embodiment 3

[0049] The dirt-resistant and antistatic dirt-resistant treatment method of nylon fiber fabric modification treatment method comprises the following steps:

[0050] (1) Nylon fiber fabrics need to be soaked in deionized water, ethanol, acetone and n-hexane in order to be fully cleaned before modification, and then dried for use. Then, place the pre-dried nylon sample in a plasma processor, adjust the power to 300W, and treat the nylon fiber fabric for 10 minutes on each side under an oxygen atmosphere to obtain a hydrophilic nylon fiber fabric;

[0051] (2) Add 20ml of ethanol, 0.5g of ferric chloride, 2ml of triethoxy (1H, 1H, 2H, 2H-nonafluorohexyl) silane into a weighing bottle, stir well, then add the nylon fiber in step (1) The fabric is soaked in NF for 10 minutes, then taken out and dried at room temperature for 3 hours;

[0052] (3) Put the nylon fiber fabric NF-F into a closed chamber filled with nitrogen, add 1ml of pyrrole, heat and react at 80°C for 20h, wash with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com