Low-trigger voltage bidirectional SCR device based on buried layer trigger

A low trigger voltage and device technology, applied in the electronic field, can solve the problems that SCR can't achieve voltage clamping and ESD protection can't be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

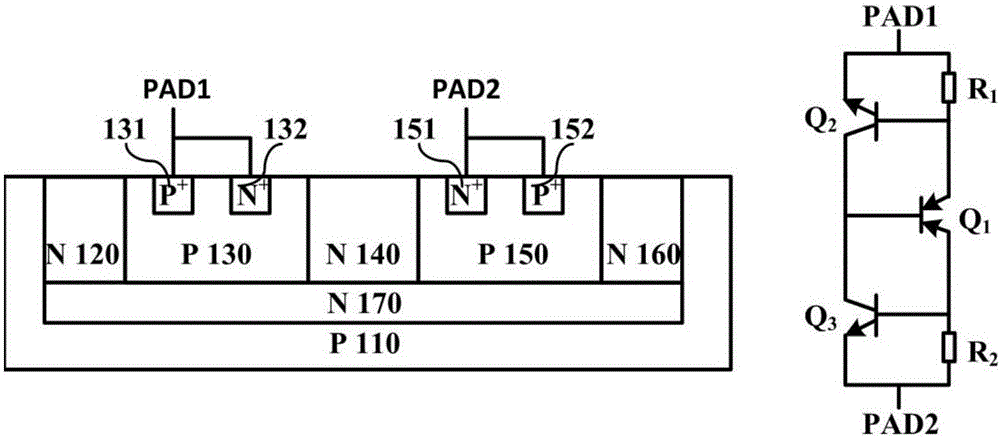

[0021] This embodiment provides a low-trigger voltage bidirectional SCR device based on buried layer triggering, and its structure diagram and equivalent circuit diagram are as follows image 3 As shown, it includes 1 main device, n trigger devices on the left side of the main device, and m trigger devices on the right side of the main device, where n≥1, m≥1;

[0022] The main device has a symmetrical structure and includes a p-type silicon substrate 110; an n-type heavily doped buried layer 170 is formed on the silicon substrate 110; an n-type well is formed on the buried layer 170 adjacent to each other from left to right Region 120, p-type well region 130, n-type well region 140, p-type well region 150, and n-type well region 160; the n-type well region 120 and n-type well region 160 are respectively provided with n-type heavily doped regions 121, 161; The p-type well region 130 is sequentially provided with a p-type heavily doped region 131, an n-type heavily doped region 132,...

Embodiment 2

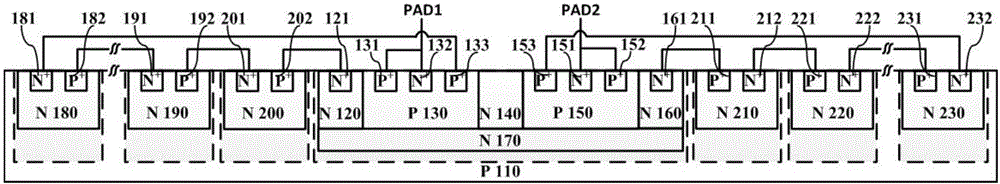

[0040] This embodiment provides a low-trigger voltage bidirectional SCR device based on buried layer triggering, and its structure diagram and equivalent circuit diagram are as follows Figure 4 As shown, it includes 1 main device, n trigger devices on the left side of the main device, and m trigger devices on the right side of the main device, where n≥1, m≥1; the structure and device of the trigger device on both sides of the main device The connection relationship between them is the same as that of Embodiment 1, and will not be repeated here. The difference is that the p-type well region 130 of the main device is sequentially provided with p-type heavily doped regions 133 and p-type heavily doped regions from left to right. The region 131, the n-type heavily doped region 132, the p-type heavily doped region 131 and the n-type heavily doped region 132 are all connected to the PAD1; the p-type well region 150 is sequentially provided with n-type heavily doped regions from left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com