Built-in oil pump motor and processing method thereof

A technology of oil pump motor and processing method, which is applied in the direction of manufacturing motor generators, electromechanical devices, electrical components, etc., which can solve the problems of large space occupation and loose overall structure, and achieve safe working process, simplified steps, and easy control of the operation of the motor The effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

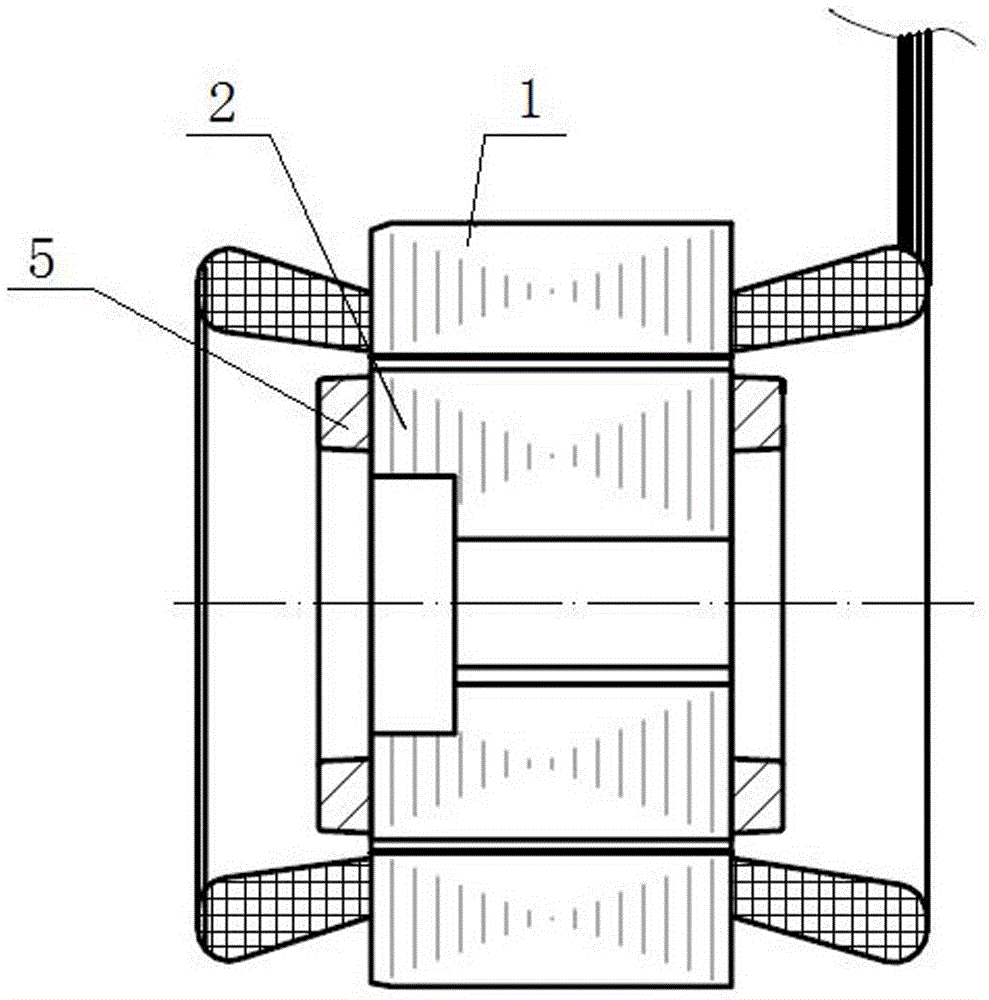

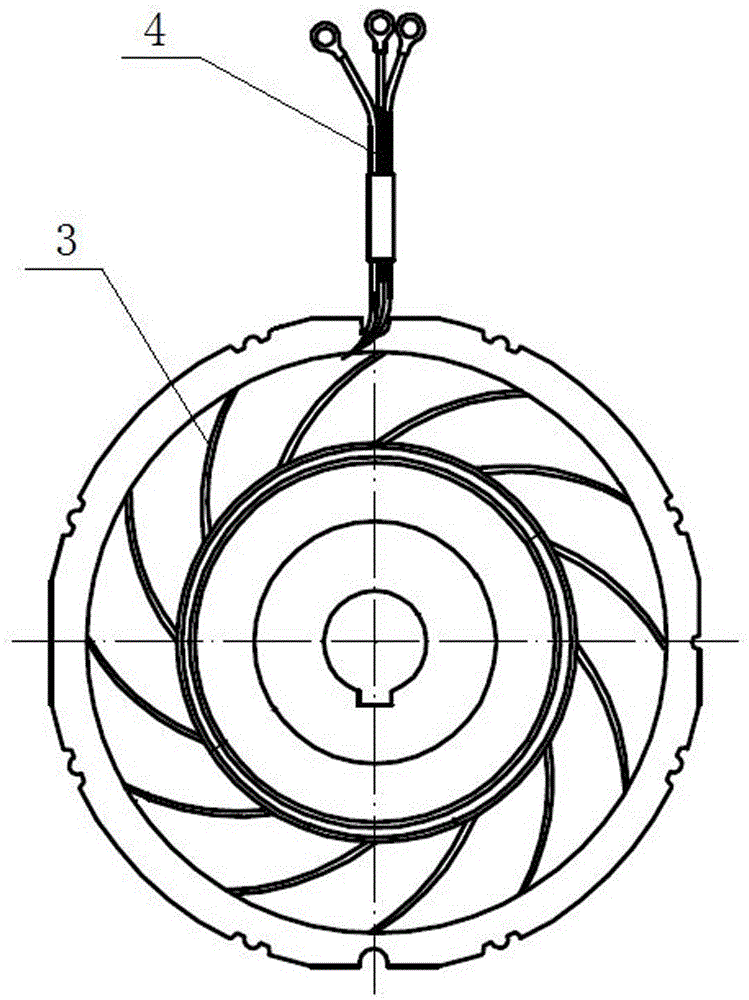

[0021] A built-in oil pump motor of the present invention, such as figure 1 with figure 2 As shown, it includes a stator core 1 and a rotor 2, which are directly installed inside the oil pump, wherein the rotor 2 is directly installed on the shaft of the oil pump, the stator core 1 is directly installed on the housing of the oil pump, and the stator core 1 is provided with Winding 3 and connecting wire 4; the stator core 1 is formed by welding and lamination of a set of stator punched pieces with stator slots; the rotor 2 is laminated by a set of cast aluminum rotor punching pieces with rotor slots The two ends are respectively provided with a rotor end ring 5; the winding 3 is provided with a temperature sensor, and the temperature sensor is a PT100 thermal resistance temperature sensor; the coil of the winding 3 is wound by a composite enameled wire, wherein the composite enameled wire includes The conductor and the insulating layer covering the conductor, wherein the conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com