Medical grinding tool

A grinding and cutting tool technology, applied in medical science, dentistry, dental drilling, etc., can solve the problems of tool movement interference, inconvenient use, unstable control, etc., to reduce treatment costs, improve surgical efficiency, and facilitate stable control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

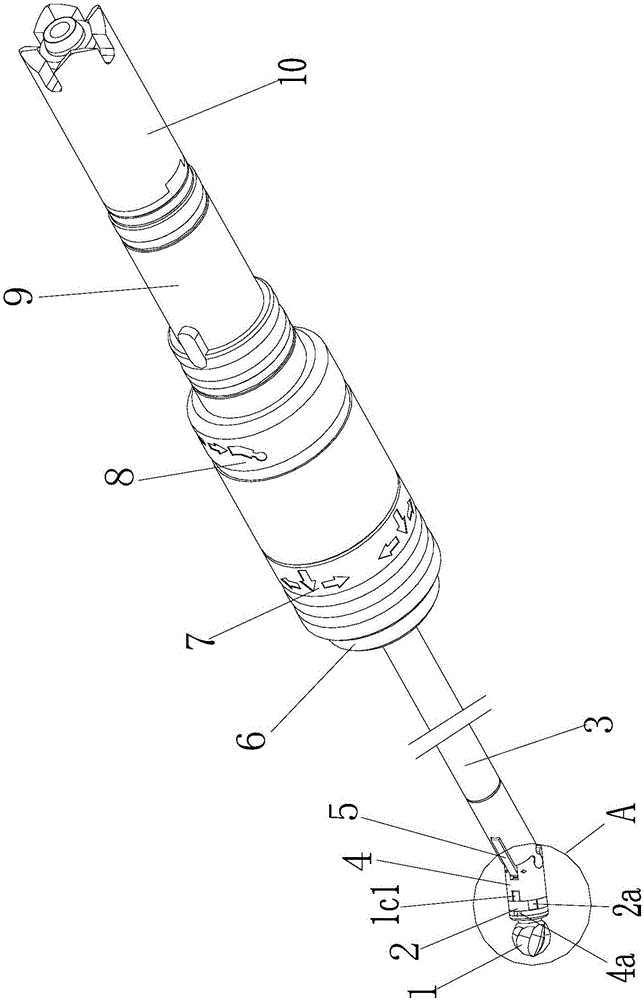

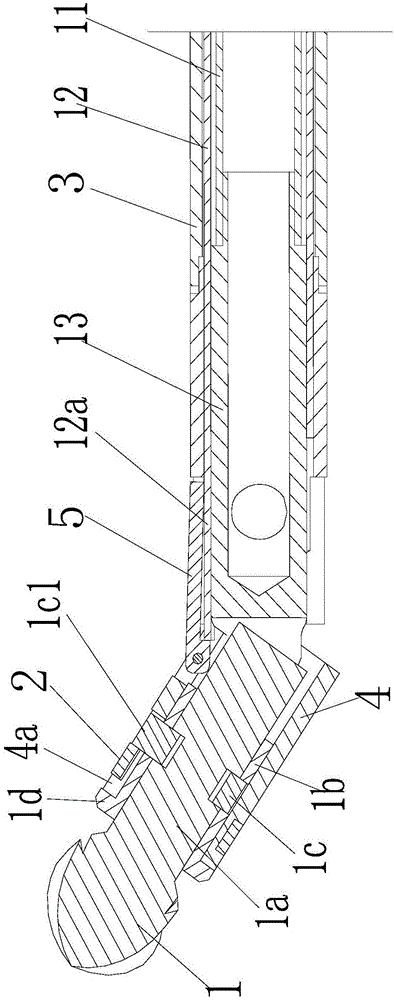

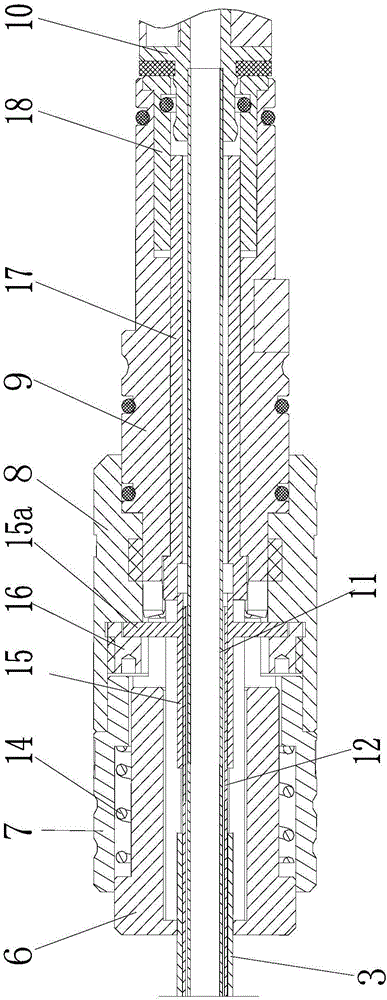

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a sectional view of the front section of the present invention, image 3 It is a sectional view of the rear section of the present invention, Figure 4 is the structure diagram of the grinding head, Figure 5 for figure 1 Enlarged view at A, Figure 6 For the purpose of hinged grinding head and inner knife tube, as shown in the figure: the medical grinding tool of this embodiment includes a knife tube assembly and a grinding head 1 installed on the front end of the knife tube assembly, and the grinding head 1 can be driven Pitch, rotation and revolution are set up; pitch refers to the rotation at a certain angle relative to the axis of the cutter tube assembly, autorotation refers to the rotation of the grinding head for grinding under the drive, and revolution refers to the movement of the entire grinding head around the cutter tube assembly The axis rotates to achieve the purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com