Vertebral compression fracture implantation filling-repairing device

A technique for compressive fractures and vertebral bodies, applied in the direction of fixers, etc., can solve the problems of incomplete filling of the vertebral body cavity, increase the risk of secondary fractures of the vertebral body, and increase the occurrence of other complications, so as to reduce pain and economic burden, control bone cement leakage, and increase the effect of bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In these drawings, the size and relative sizes of layers and regions may be exaggerated for clarity.

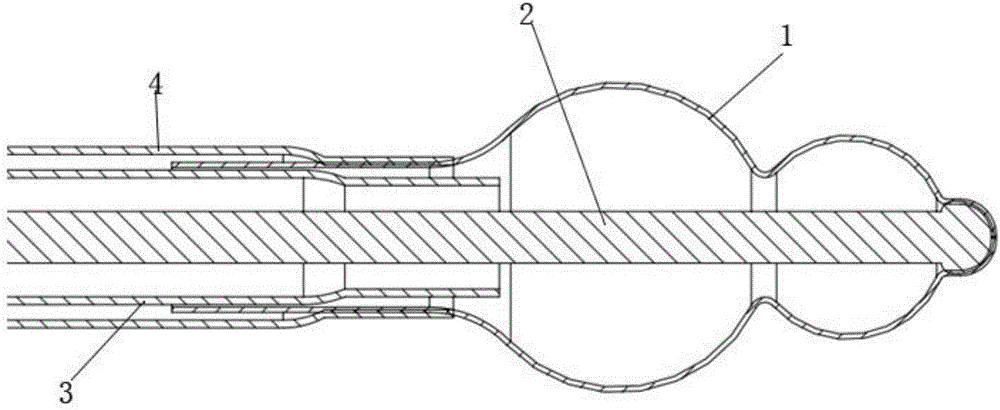

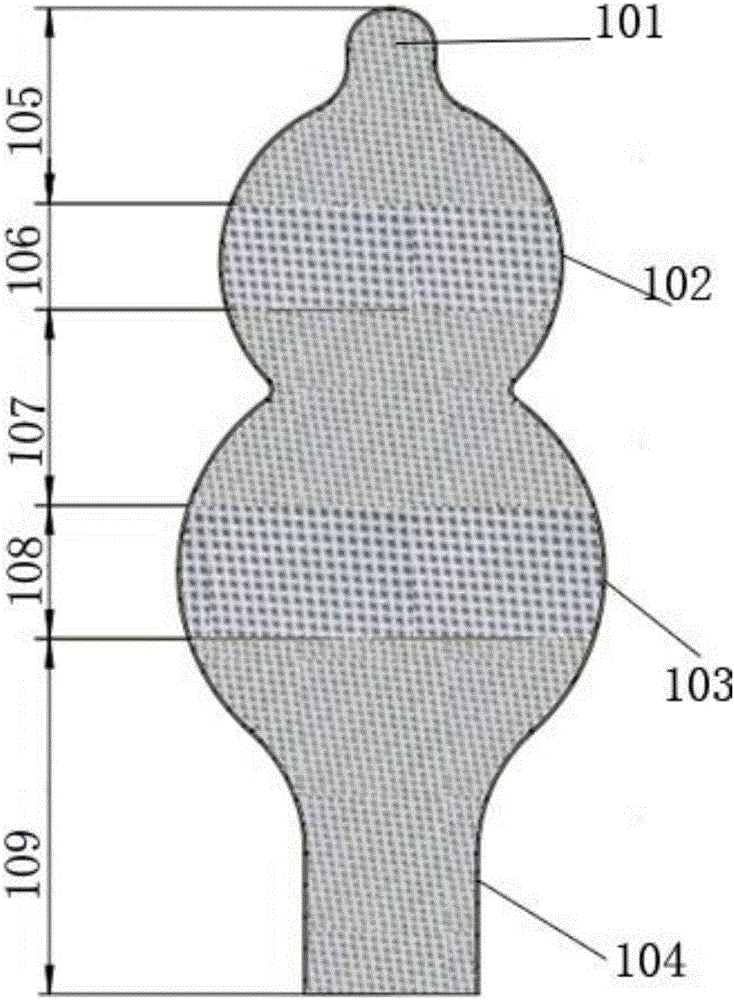

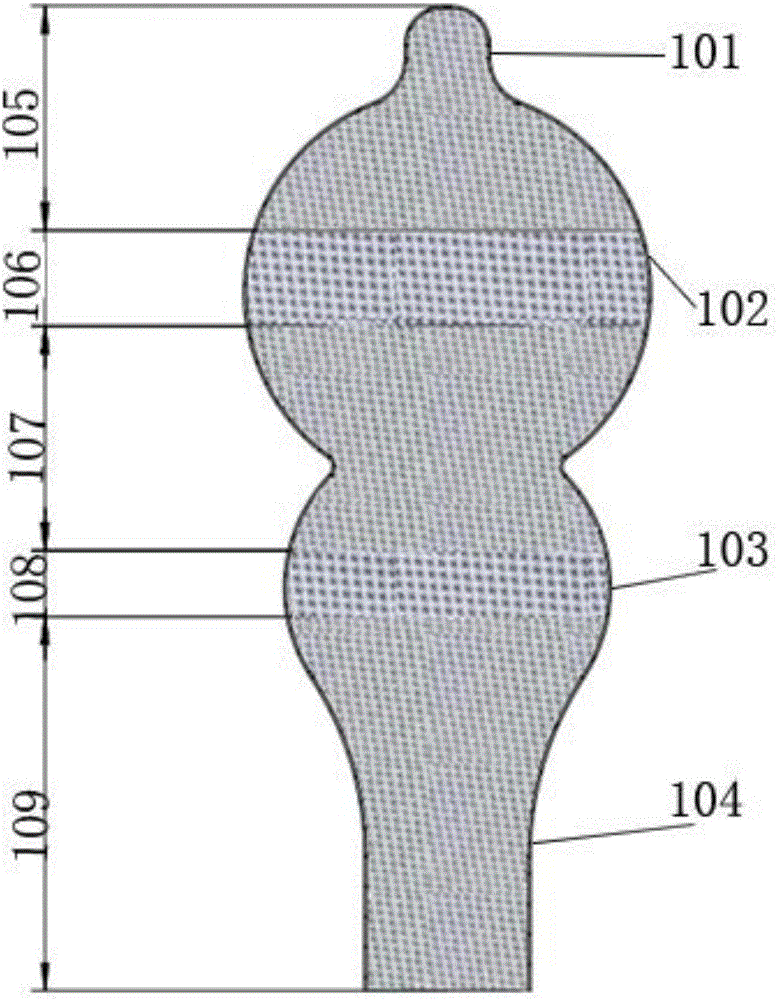

[0029] refer to Figure 1-7 As shown, the present invention provides a kind of implant filling and repairing device for vertebral body compression fracture, comprising a fabric capsule body 1, and the fabric capsule body 1 is in the shape of a sub-cucurbit after being stretched (the sub-cucurbit shape is the shape of a sub-waist gourd) similar shape), the fabric capsule body 1 as a whole is a mesh structure woven by polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com