Novel gear machining tool

A technology for machining tools and gears, applied in the field of new gear machining tools, can solve problems such as poor meshing, knife punching, stress concentration at inflection points, etc., to improve strength and service life, increase fillet radius size, and avoid tool stress concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

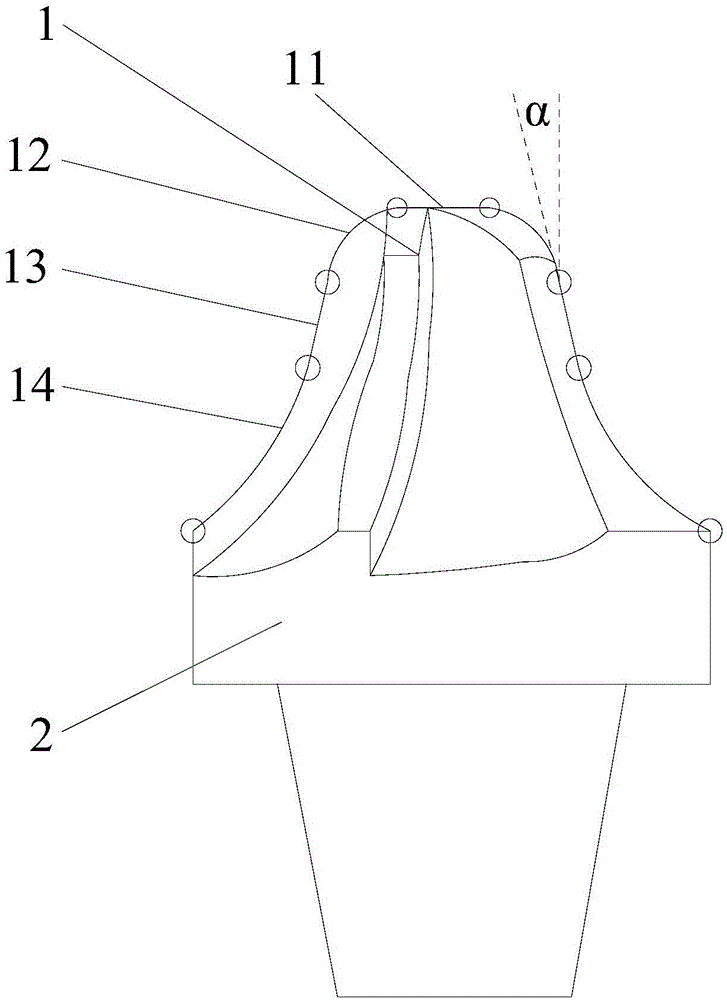

[0017] The inclination angle α of the oblique line portion is 3.5°, and the radius of the arc portion is in the range of 9mm-11mm.

Embodiment 2

[0019] According to the above structure, the preferred inclination angle α of the oblique portion 13 in the present invention is 3°9′6″, and the radius of the rounded corner of the arc portion 12 is 8.6 mm.

Embodiment 3

[0021] According to the above structure, the preferred inclination angle α of the oblique portion 13 in the present invention is 3°25′54″, and the radius of the arc portion 12 is 12 mm.

[0022] The present invention increases the size of the radius of the arc part 12 of the tool by optimizing the structure of the machining tool, and improves the strength and service life of the tool. The oblique line part 13 is used between the involute part 14 and the arc part 12. The transition connection can eliminate the inflection point, avoid tool stress concentration, and solve the problem of tool breakage and cutting during gear machining. It has the characteristics of high quality, high efficiency, and low consumption for gear machining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Radius size | aaaaa | aaaaa |

| Radius size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com