High-temperature superconductivity magnetic levitation system and magnetic levitation train

A high-temperature superconducting and magnetic levitation technology, which is used in sliding/floating railway systems, motor vehicles, electric vehicles, etc., can solve the problem that the high-temperature superconducting magnetic levitation system does not obtain better results, and achieves improved magnetic field utilization and suspension force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

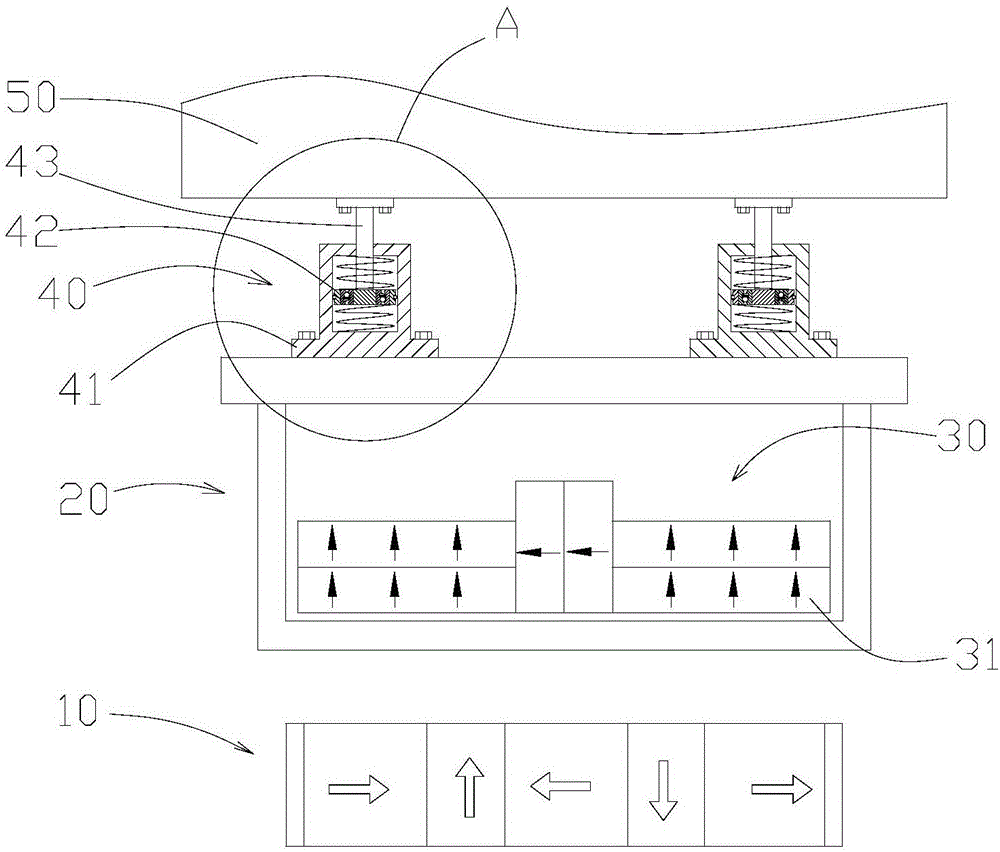

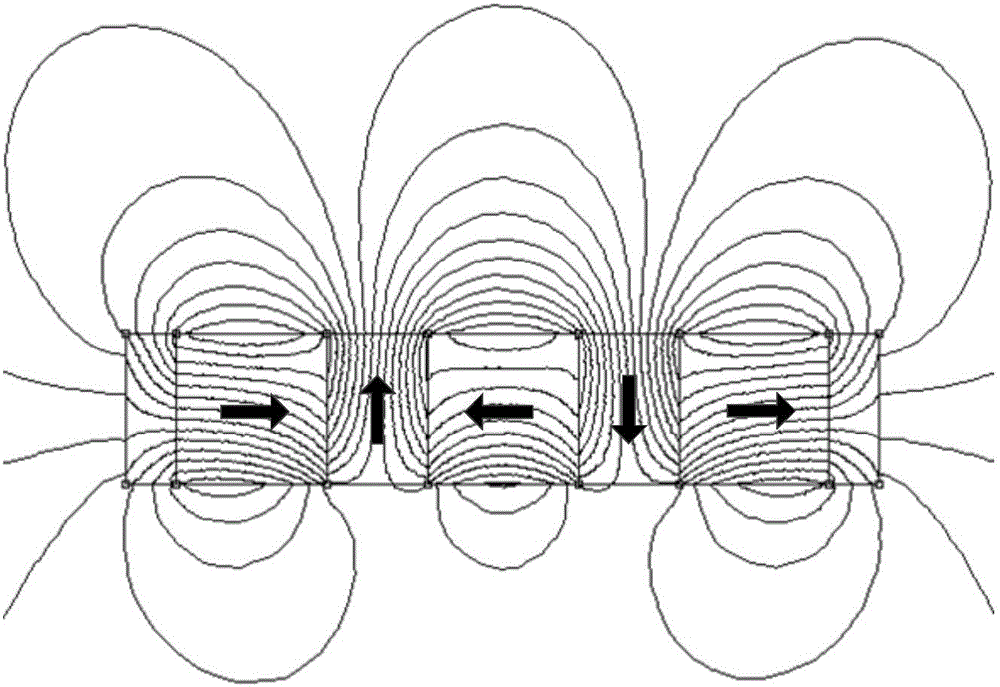

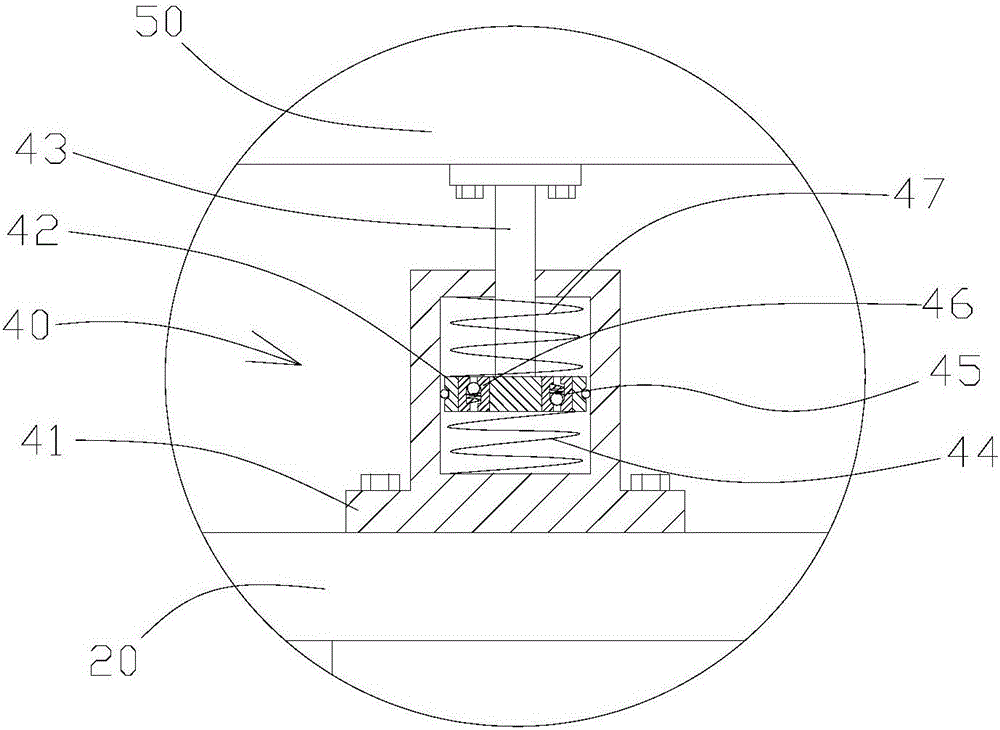

[0018] Such as figure 1 As shown, the preferred embodiment of the present invention discloses a high-temperature superconducting maglev system, which can be applied to rail 10 transportation vehicles but is not limited thereto. The high temperature superconducting maglev system includes a magnetic levitation mechanism and a buffer mechanism 40, the magnetic levitation mechanism is used to provide suspension force and guiding force for the vehicle so that the vehicle can run under a certain load condition, and the buffer mechanism 40 is used to slow down the vertical movement of the vehicle. Movement to cushion the vibrations that occur when the vehicle is in motion. Among them, the magnetic levitation mechanism specifically incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com