A pool bottom structure for producing ultra-clear glass

A technology of ultra-clear glass and pool bottom, applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve the problems of unfavorable microbubble clarification and dispersal, great influence of reflux at clarification place, thick glass flow layer, etc., to achieve Improve homogenization and clarification effects, improve melting efficiency, and reduce viscous layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

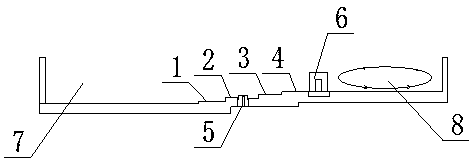

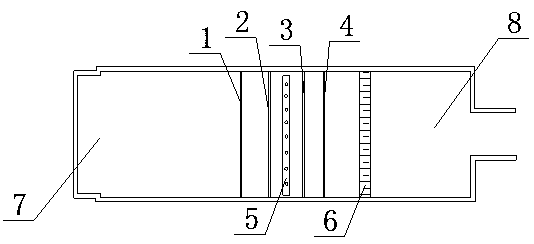

[0022] This program is implemented in this way, please refer to figure 1 and figure 2 .

[0023] 1. Structural composition. Before the hot spot at the feeding port 7 at the bottom of the pool, the feeding liquid flow will be formed, causing fluctuations in the fluctuating liquid flow at the bottom of the pool. The other is the forming liquid flow at the clarification place after the hot spot. The first step 1 is set on the right side of the feeding port 7, the height is 0.1m, the second step 2 is set on the right side of the first step 1, the height is 0.1m, and the third step 3 is set on the right side of the second step 2, and the height is 0.1m m, the right side of the third step 3 is provided with the fourth step 4 with a height of 0.1m, a kiln ridge 6 is set on the right side of the fourth step 4, the height of the kiln ridge 6 is 0.75m, and the depth of the clarification part 8 is 1.1m. The mouth 7 has a depth of 1.5m. Preferably, a plurality of grooves are arranged l...

Embodiment 2

[0025] This program is implemented in this way, please refer to figure 1 and figure 2 .

[0026] Structural composition, the feeding port 7 at the bottom of the pool is before the hot spot, and the feeding liquid flow will be formed, causing the fluctuating liquid flow at the bottom of the pool to fluctuate, and the other is the forming liquid flow at the clarification place after the hot spot. The first step 1 is set on the right side of the place 7, and the height is 0.2m. The second step 2 is set on the right side of the first step 1, and the height is 0.2m. The third step 3 is set on the right side of the second step 2, and the height is 0.2m. The right side of the third step 3 is provided with a fourth step 4 with a height of 0.2m. A kiln ridge 6 is set on the right side of the fourth step 4. The height of the kiln ridge 6 is 0.5m, the depth of the clarification is 0.7m, and the feeding port is 7 The depth is 1.5m. Preferably, multiple grooves are arranged horizontally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com