Method of manufacturing sofa cut pile

A production method and technology of cutting flannel, which are applied in the direction of cutting loop, textile, fabric, etc., can solve the problems of poor product quality and easy occurrence of hair loss, and achieve the effects of good product quality, good wear resistance, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

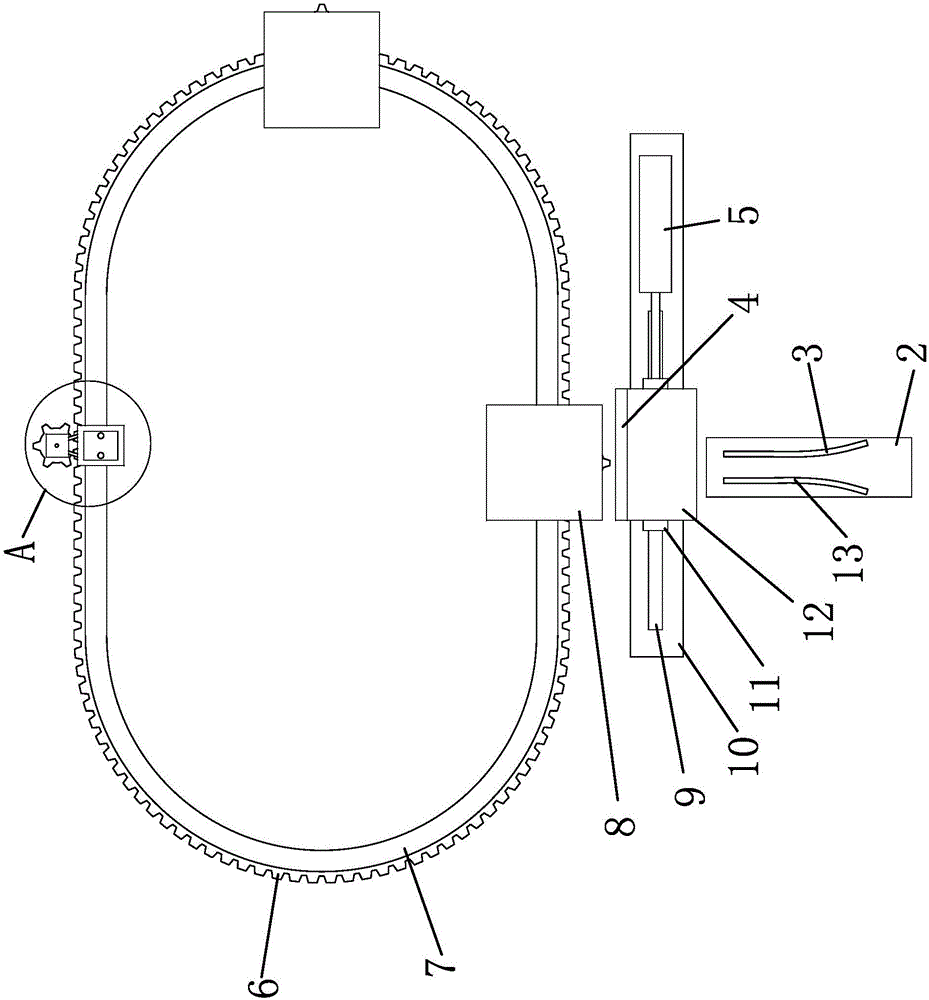

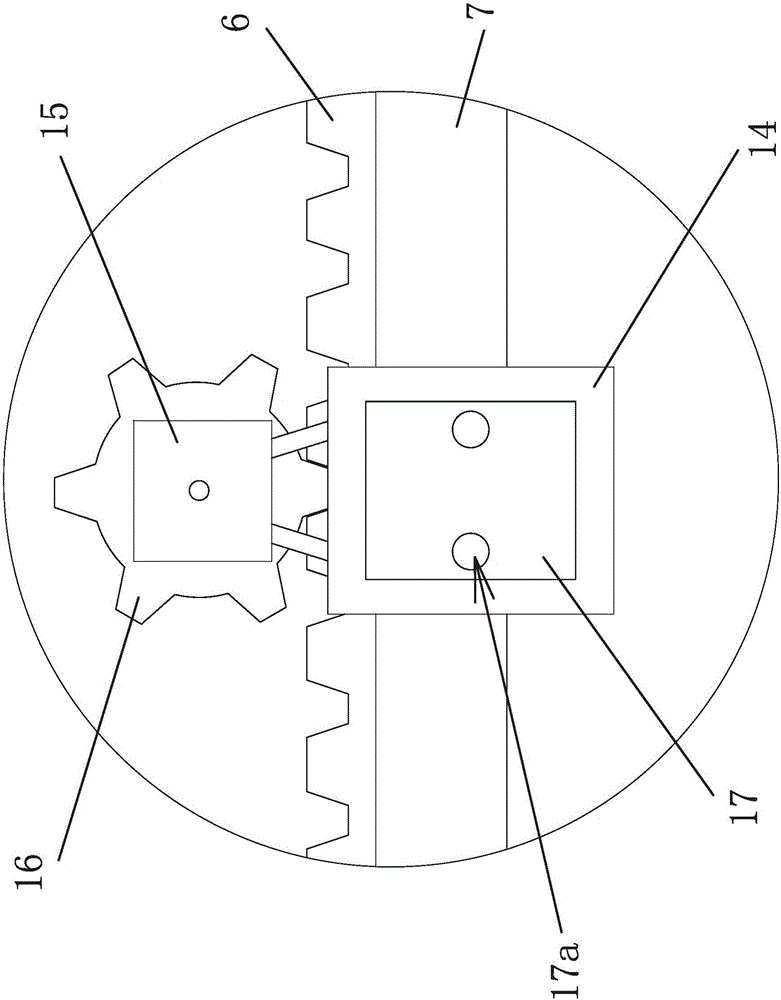

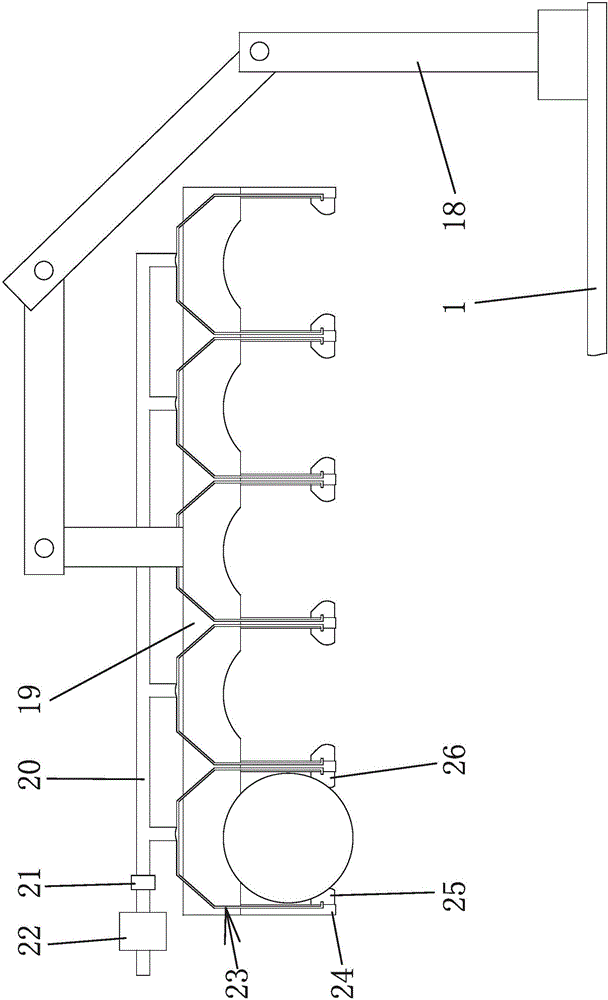

[0061] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0062] The preparation method of the sofa cut velvet cloth, the method comprises the following steps:

[0063] a, material preparation: take rayon as velvet warp, take large chemical fiber as bottom warp, get large chemical fiber and thermal fuse as weft yarn, and use it as raw material for standby; in this embodiment, 6S / 2 rayon can be used as velvet warp, 32S / 2 large chemical fiber is used as the bottom warp, 21S / 2 large chemical fiber and 150D / 2 thermal fuse are used as weft yarns; artificial cotton and large chemical fiber adopt existing products available on the market, and thermal fuse adopts all commercially available products Melted polyester filament;

[0064] B, weaving: the raw material is woven by common knit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com