Crushing system for cement pavement resonance crusher

A cement pavement and crushing system technology, which is applied in the field of maintenance machinery and road construction, can solve the problems of shear rubber shock absorber heat generation and high performance requirements, low energy utilization rate, and high engine power, etc., to achieve energy improvement Utilization rate, prevention of front and rear and left and right irregular beating, and large impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

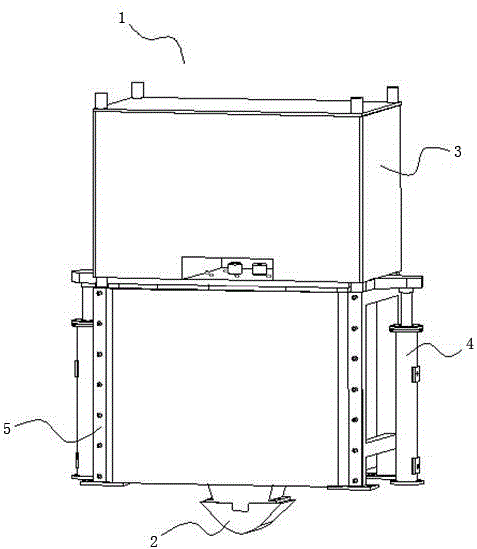

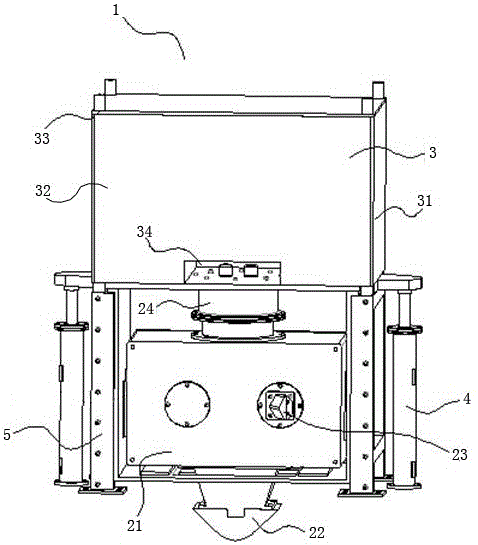

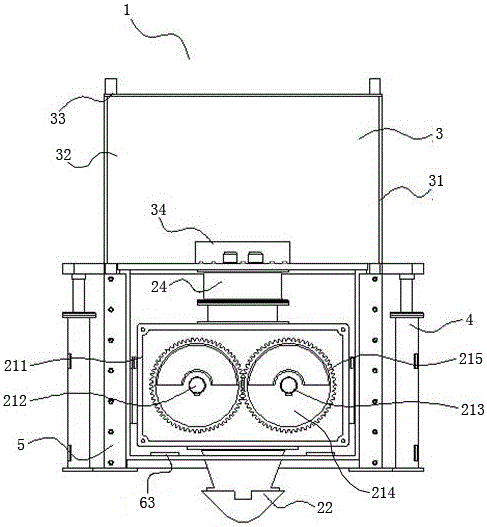

[0055] Embodiment 1: as Figure 1-4 As shown, a current preferred embodiment of the crushing system for the resonance crusher in the present invention is shown, and the crushing system unit in the preferred embodiment is generally designated by reference numeral 1 . In the preferred embodiment shown, the crushing system includes a vibration excitation system 2, a counter force device 3, a lifting mechanism 4 and a support frame 5, and the vibration excitation system 2 is used to input power and convert power into vibration force At the same time, the exciting force is transmitted to the cement concrete pavement that needs to be broken. The counter force device 3 is a supporting structure, which is used to provide counter force for the exciting system and reduce the vibration of the whole resonance crusher. The lifting mechanism 4 Used to realize the lifting of the vibration excitation system and the counter force device in the non-working state and the landing in the working s...

Embodiment 2

[0094] Embodiment 2: as Figure 13-16 As shown, another preferred embodiment of the crushing system used in the resonance crusher in the present invention is shown, wherein the reaction force device 3 is a floating structure, and the reaction force device 3 includes a counterweight device 31 , the counterweight device 31 is connected to the lifting lug 526 on the top of the mounting frame 52 through the connecting part 35 at the bottom, the counterforce device 3 is connected to the lifting mechanism 4, and symmetrically arranged on both sides of the counterweight device 31 Lifting plate 36, the driving part of the lifting mechanism 4 acts on the lifting plate 36, and the lifting mechanism 4 drives the counter force device 3, the mounting frame 52 and the vibration excitation system 2 to lift synchronously in the vertical direction. The lifting mechanism 4 is not stressed during the working process of the crusher, and the counterweight device 31 is in the working process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com