A kind of butyl hot melt adhesive warm edge spacer

A warm-edge spacer and butyl hot-melt adhesive technology, which is applied to building components, buildings, parallel glass structures, etc., can solve the problem of difficulty in maintaining the stability of the overall shape of the insulating glass thickness, size, production, storage, transportation, and installation of insulating glass. Problems such as large-scale promotion and application cannot be obtained, and the effects of improving water absorption performance, simple structure, and convenient production are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

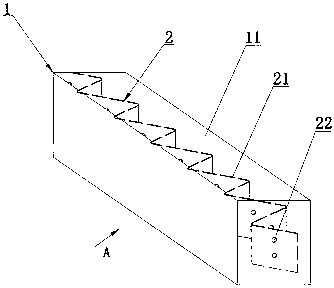

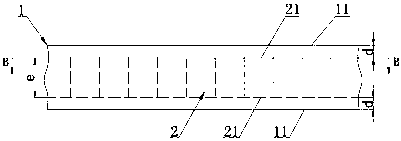

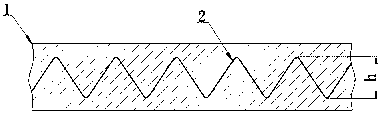

[0016] Such as figure 1 , figure 2 , image 3 As shown, a kind of butyl hot melt adhesive warm edge spacer according to the present invention comprises: a warm edge spacer matrix 1 made of butyl hot melt adhesive, and the cross-sectional shape of the warm edge spacer matrix 1 is Rectangular, this shape of butyl hot melt adhesive warm edge spacer can be applied to most of the insulating glass, and can fit better with the glass surface, easy to seal; the warm edge spacer matrix 1 is mixed with dry Molecular sieve, which can improve the water absorption performance of the butyl hot melt adhesive warm edge spacer; in the warm edge spacer matrix 1, a corrugated support plate 2 made of plastic material with low thermal conductivity is arranged, and the corrugated support plate 2 Wrapped in the warm edge spacer matrix 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com