Backfill device and backfill method for chambers formed during exploitation of natural gas hydrate in seafloor

A hydrate and natural gas technology, applied in mining equipment, mining fluids, safety devices, etc., can solve the problem of reduced stability of hydrate-occurring formations and overlying formations, reduced structural strength of mining work areas, and complicated backfilling methods and processes and other issues, to achieve the effect of reducing the cost of hydrate mining, improving the safety of the project, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

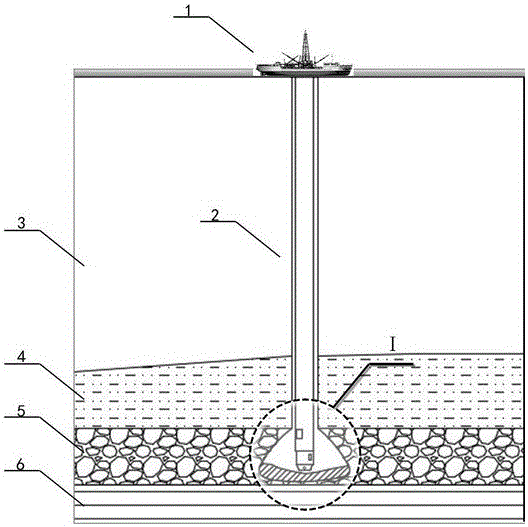

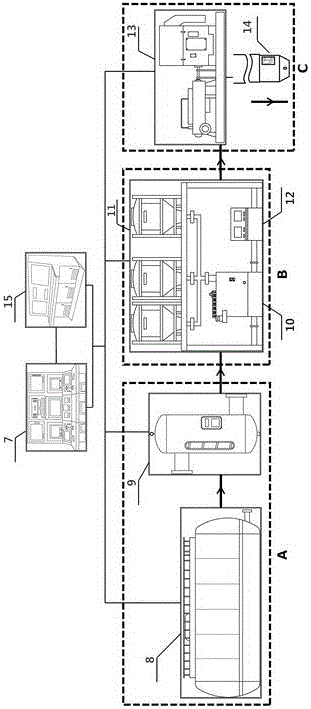

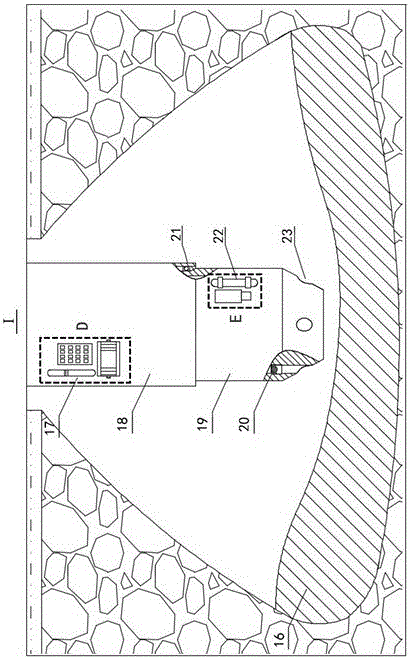

[0028] Such as figure 1 , figure 2 with image 3 As shown, a chamber backfill device used in the exploitation of seabed natural gas hydrates in the present invention is composed of an in-situ chamber condition monitoring system D, a raw material collection system A, a batching system B, a pumping injection system C, and a backfill effect detection system Composed of E, the chamber situation in-situ monitoring system D is composed of the chamber situation comprehensive measurement equipment 7 and the chamber situation collection unit 17, the digital signal of the chamber situation collection unit 17 is transmitted to the chamber situation comprehensive measurement equipment 7 through a special cable, Three-dimensional visual monitoring of complex conditions in the chamber;

[0029] The raw material collection system A is composed of a storage tank 8 and a filter box 9, which is used to store and record the amount of returned slurry, and process the slurry as backfill raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com