Waste heat circulation system for direct air cooling tower

A circulation system and air cooling tower technology, applied in lighting and heating equipment, indirect carbon dioxide emission reduction, steam/steam condenser, etc., can solve the problems of waste heat source, temperature increase, thermal pollution, etc., to improve utilization rate and alleviate low temperature Corrosion and thermal pollution reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

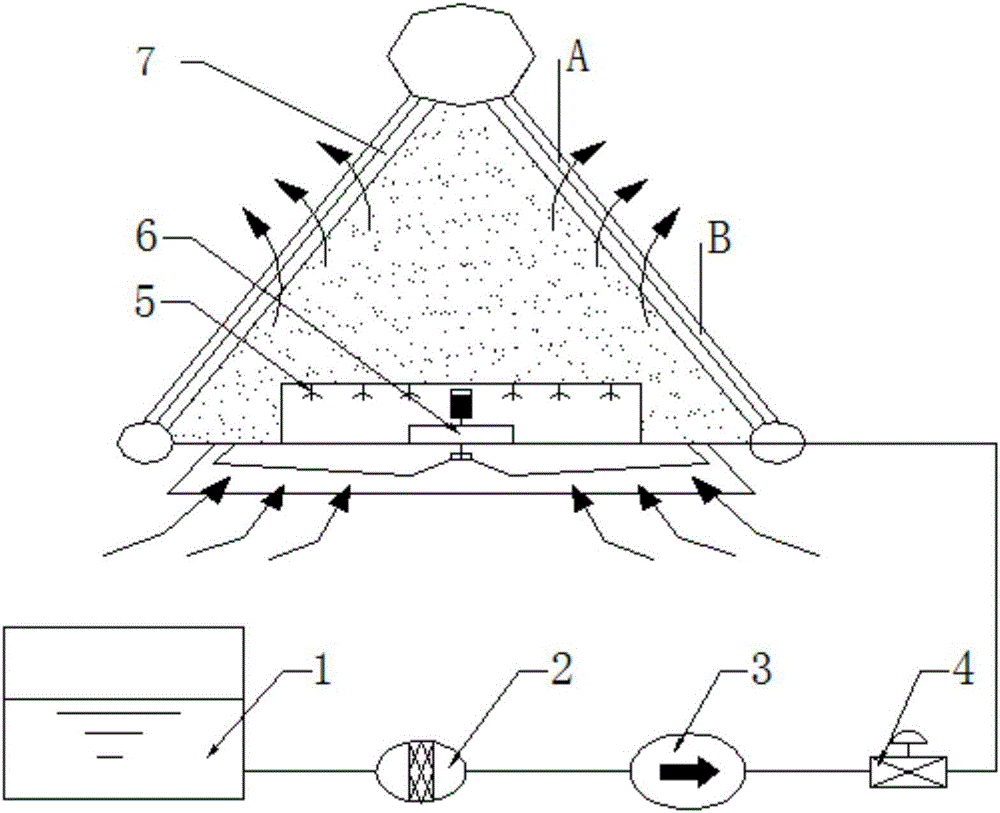

[0017] Such as figure 1 As shown, the present invention discloses a direct air-cooling tower waste heat circulation system. The front part of the system includes a desalinated water tank 1, a filter screen 2, a high-pressure pump 3 and an air-cooling unit 7 connected by pipelines in sequence, wherein the finned tubes in the air-cooling unit 7 The direct air-cooling tower structure is formed by slanting. There is a regulating valve 4 between the high-pressure pump 3 and the inside of the air-cooling tower. The fan 6 is located below the air-cooling tower. There is a nozzle 5 above the fan 6. The fan 6 sucks air at normal temperature from the outside. Flow through the nozzle 5 to the inside of the air cooling unit 7 above.

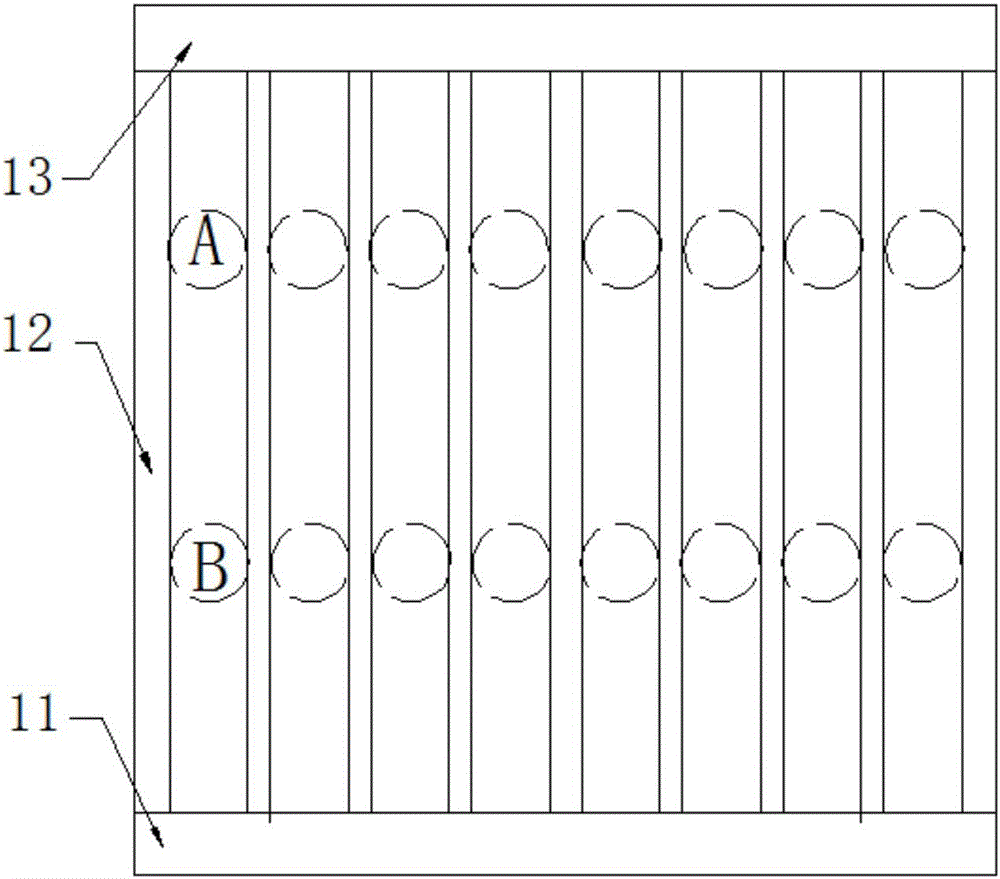

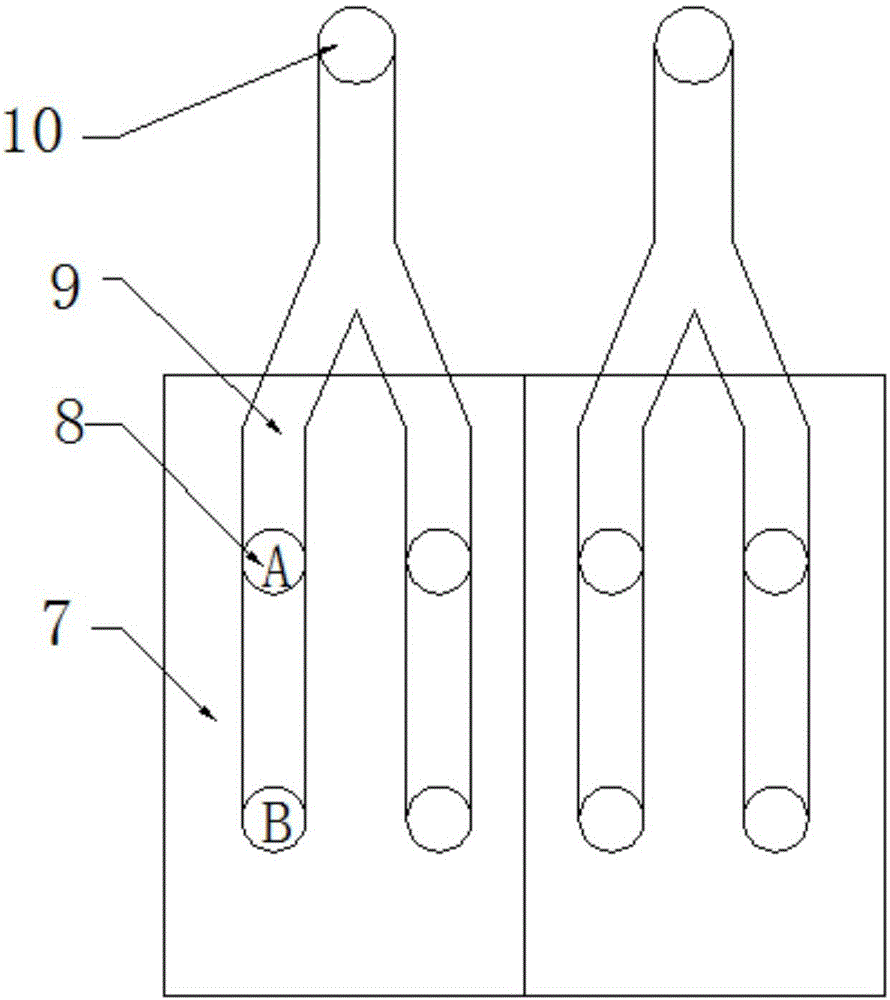

[0018] Such as figure 2 As shown, the air-cooling unit 7 located on the slope of the direct air-cooling tower is provided with a plurality of finned tubes 12 as condensers, the upper ends of the finned tubes 12 are connected with the exhaust steam pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com