Explosion diode based on detonation wave corner effect

A corner effect and detonation wave technology, applied in the field of explosive diodes, can solve problems such as property loss, casualties, safety accidents, etc., and achieve the effects of reducing transportation safety, flexible and diverse forms, and preventing huge losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

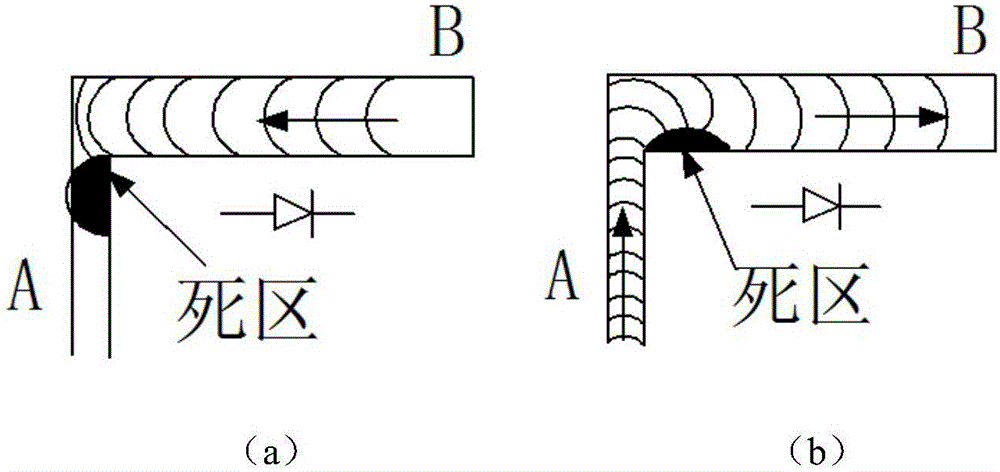

Problems solved by technology

Method used

Image

Examples

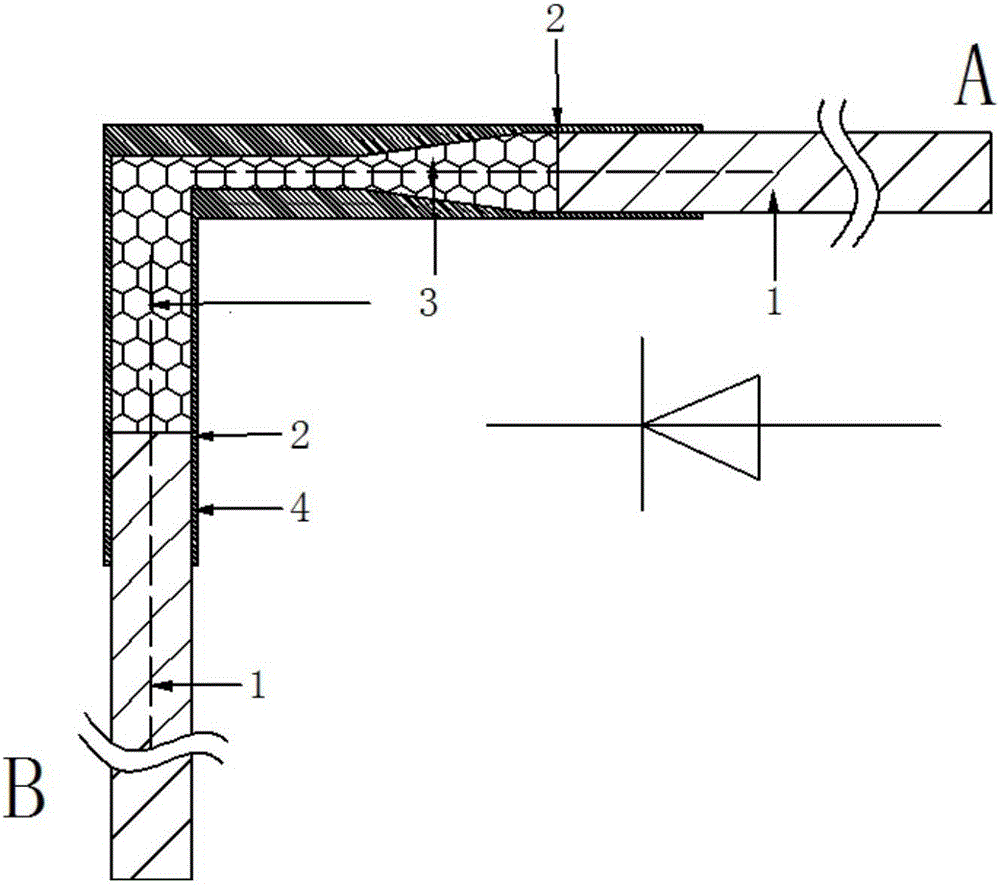

Embodiment 1

[0024] figure 2 That is the structural diagram of the explosive diode of the present invention, corresponding to the working conditions: A is used as the detonating end, B is used as the output end, the outer diameter of the shell is 6.8mm, the inner diameter of the input port is 6mm, and there is a positioning step at 12mm deep into the port, and then the inner diameter begins to gradually Reduced to 3mm, held to the corners. Put the detonating cord into the B end, go deep into the positioning step 2 inside the nozzle, and fix the detonating cord to the shell with a closing machine. Then put the booster Taian (density 0.88g / cm2) from the input end 3 ) to the positioning step of the input end, and finally put in the detonating cord, squeeze and fix it on the shell with a closing machine. Finally, put an iron sheet at the detonating cord at the output end B as a verification board. When the detonating cord at the output end detonates, a pit will be left on the iron sheet, wh...

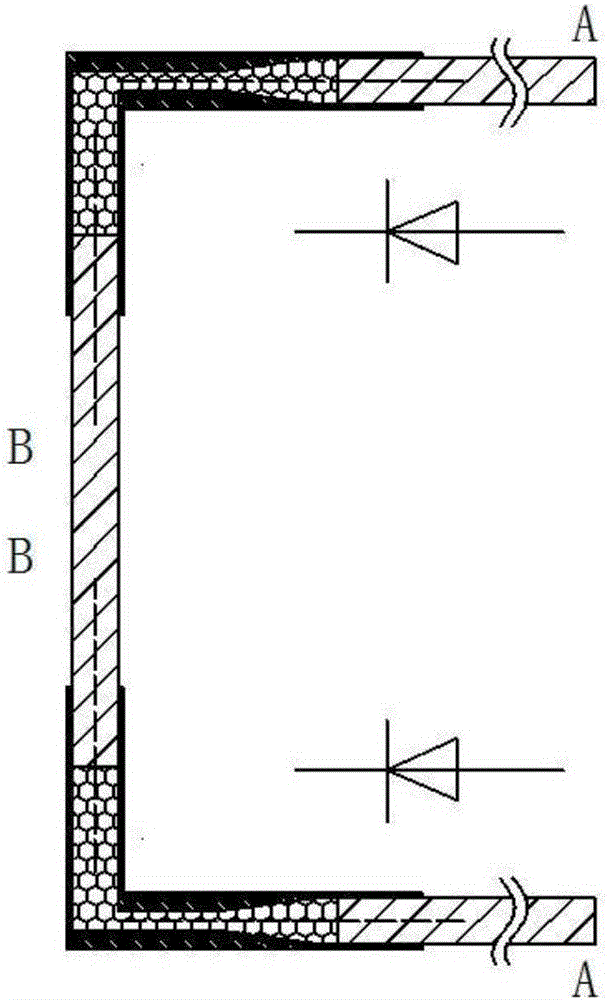

Embodiment 2

[0026] according to image 3 Schematic diagram to make an explosive diode device with a positive and negative symmetrical structure. This structure is completely symmetrical, and it can conduct positive and stable explosion transmission and reverse reliable explosion prevention experiments at one time. Choose the iron shell, according to the attached image 3 As shown, assemble, now connect the detonating cord and rubber plug at the B end to the wall of the tube shell, then install it into Taian from the other section, and finally install the detonating cord. The entire charge structure is completely symmetrical, and then one end is selected as the detonating end, then the charge of the tube shell is used as the forward explosion transfer experiment, and the other tube shell is used as the reverse flameproof end, marked and detonated. The test was repeated 10 times, and the results showed that the one at the detonating end detonated normally, while the one at the flameproof e...

Embodiment 3

[0028] Such as Figure 4 As shown, make series explosive diodes, 10 rounds of explosive diodes are connected in series, and detonate from the positive direction A. The experiment found that the explosive diodes detonated sequentially. The results show that the explosive diode has a very stable forward transmission capability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com