Test system for gas repeated explosion of simulated coal mine diagonal connection roadway net

A test system and network technology, applied in the direction of material explosion, can solve the problems of less repeated gas explosion, unclear mechanism and influencing factors, large casualties and property losses, etc., and achieve simple structure, flexible combination and comprehensive The effect of many functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

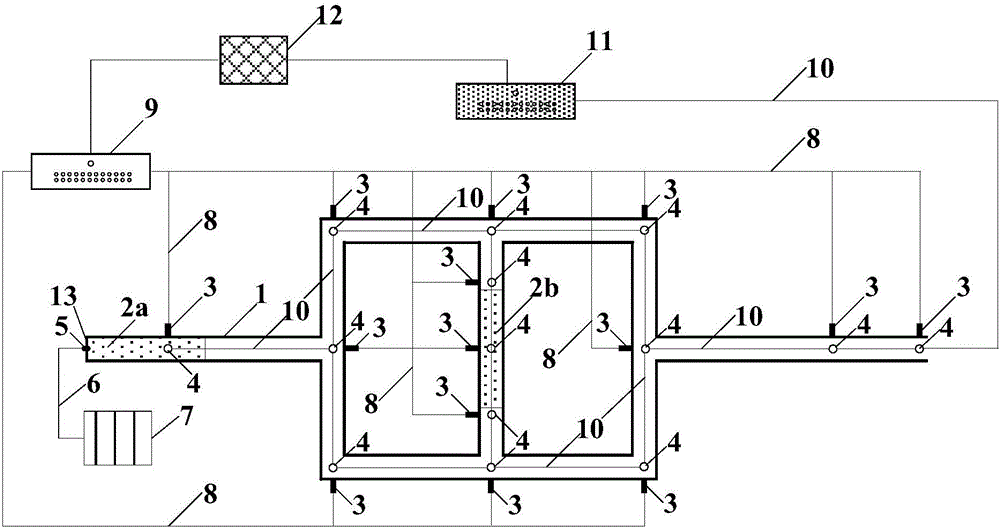

[0015] Embodiment one, as figure 1 As shown in the figure, a test system for simulating repeated gas explosions in a coal mine corner network consists of a simulated coal mine corner network 1, two methane-air premixed air bags 2a set in the simulated coal mine corner network 1, and 2b. The high-frequency flame sensor 3 and the high-frequency pressure sensor 4 set on the outer wall surface of the simulated coal mine corner network 1, and the high-voltage discharge spark plug 5 with one end extending into the previous methane-air premixed gas bag 2a, through the high-voltage shield The high-voltage discharge igniter 7 connected to the other end of the high-voltage discharge spark plug 5 by the cable 6, the flame data collector 9 connected to the high-frequency flame sensor 3 through the flame signal transmission line 8, the pressure sensor 4 connected to the high-frequency pressure sensor 4 through the pressure signal transmission line 10 Data collector 11, the data processor 1...

Embodiment 2

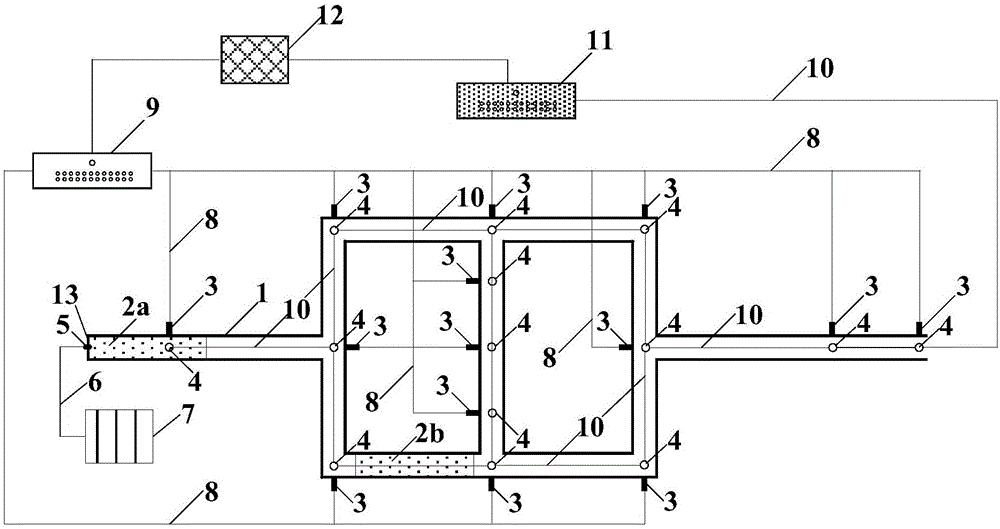

[0016] Embodiment two, such as figure 2 As shown in the figure, a test system for simulating repeated gas explosions in a coal mine corner network consists of a simulated coal mine corner network 1, two methane-air premixed air bags 2a set in the simulated coal mine corner network 1, and 2b. The high-frequency flame sensor 3 and the high-frequency pressure sensor 4 set on the outer wall surface of the simulated coal mine corner network 1, and the high-voltage discharge spark plug 5 with one end extending into the previous methane-air premixed gas bag 2a, through the high-voltage shield The high-voltage discharge igniter 7 connected to the other end of the high-voltage discharge spark plug 5 by the cable 6, the flame data collector 9 connected to the high-frequency flame sensor 3 through the flame signal transmission line 8, the pressure sensor 4 connected to the high-frequency pressure sensor 4 through the pressure signal transmission line 10 Data collector 11, the data proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com