Construction method for enabling underground pipeline to horizontally and directionally penetrate through complex gravel-cobble stratum

A horizontal directional, underground pipeline technology, applied in directional drilling, drilling equipment and methods, earthwork drilling, etc., can solve the problem of not being able to meet high-density pebble strata, unable to evaluate the relative distribution of pebble strata, unable to detect pebble and gravel strata etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

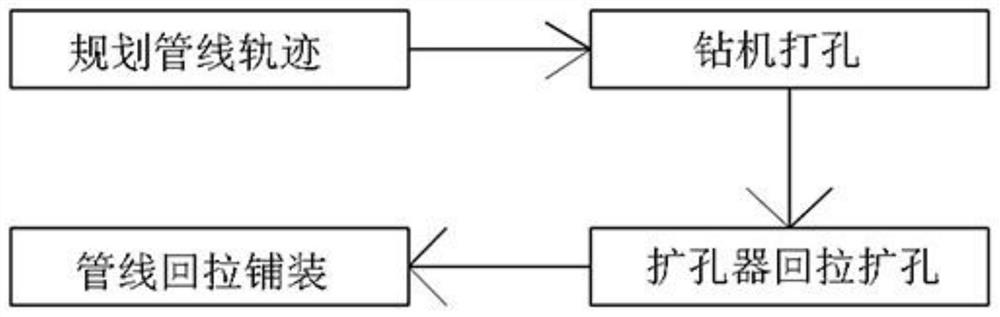

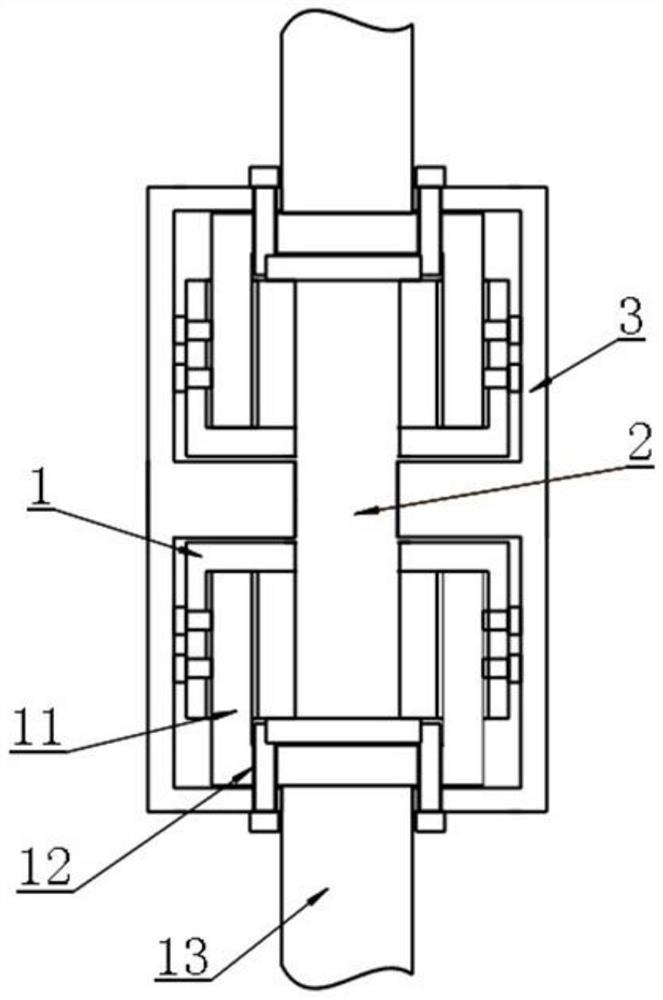

[0027] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Image 6 As shown, a construction method for underground pipelines horizontally directional passing through complex pebble formations is characterized in that it includes the following steps in sequence:

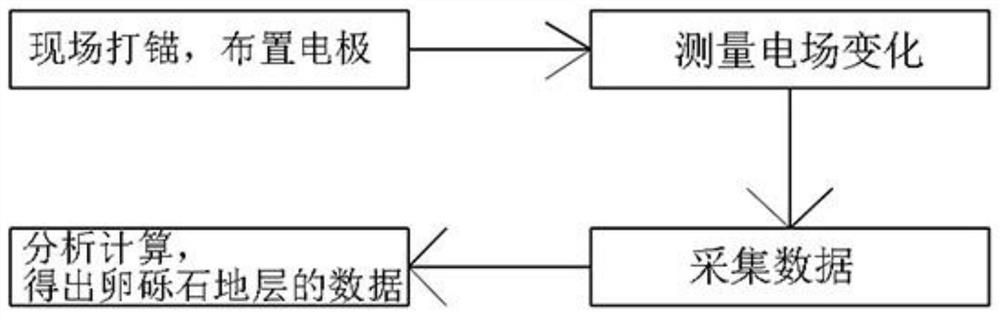

[0028] S1. To plan the pipeline trajectory, it is necessary to explore the pebble formation through high-density electrical method and drilling exploration method, and adjust the pipeline trajectory to reduce the probability of encountering the pebble formation;

[0029] S2. To drill a hole with a drilling rig, it is necessary to assemble a drill pipe of a suitable length, install a suitable type of drill bit, open the channel according to the pipeline track, and discharge the mud during the drilling process;

[0030] S3. The reamer pulls back and reams the hole, that is, adopts the multi-stage step-by-step pull-back reaming method to obtain a hole with a diameter sufficient for pipeline laying;

[0031] S4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com