On-line automatic compensation resistance tester

A resistance tester and automatic compensation technology, applied in the direction of measuring resistance/reactance/impedance, instruments, measuring devices, etc., can solve the problems of inability to automatically switch the magnification, affecting the detection accuracy and detection efficiency, and improve the detection accuracy and detection efficiency. The efficiency of improving the applicability and detection efficiency, the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

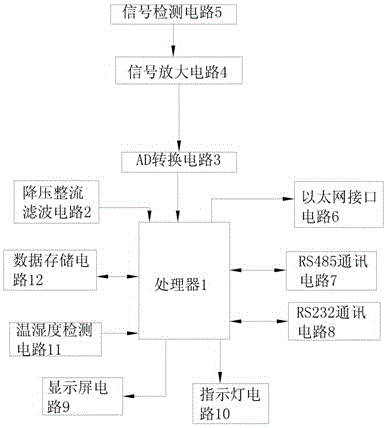

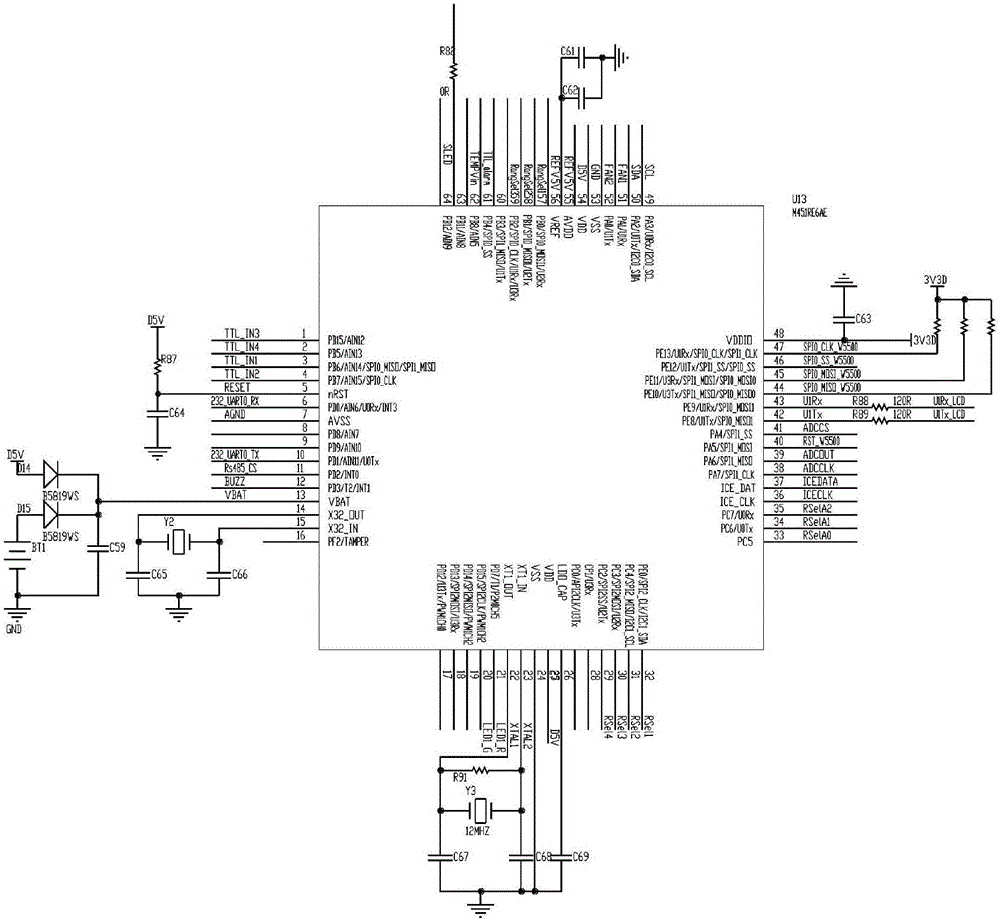

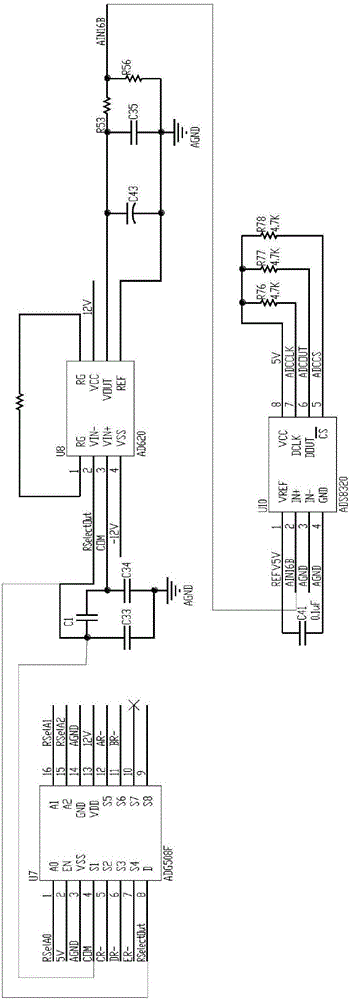

[0016] Figure 1 to Figure 4 A specific embodiment of the invention is shown in which figure 1 It is a structural block diagram of the present invention; figure 2 It is a specific circuit diagram of the processor circuit of the present invention; image 3 It is a specific circuit diagram of the signal detection circuit of the present invention; Figure 4 It is a specific circuit diagram of the constant current source detection circuit of the present invention.

[0017] See Figure 1 to Figure 4 , an online automatic compensation resistance tester, comprising a processor 1, a step-down rectification filter circuit 2 connected to the processor 1, an AD conversion circuit 3 connected to the processor 1, and the AD conversion circuit The signal amplifying circuit 4 connected to the signal input end of the circuit 3, the four groups of signal detection circuits 5 connected to the input end of the signal amplifying circuit 4, the Ethernet interface circuit 6 connected to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com