Control system and control method for process control of distribution of technology equipment

A technology on the equipment and equipment side, applied in the field of control systems, to achieve the effect of optimizing energy consumption and optimizing adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

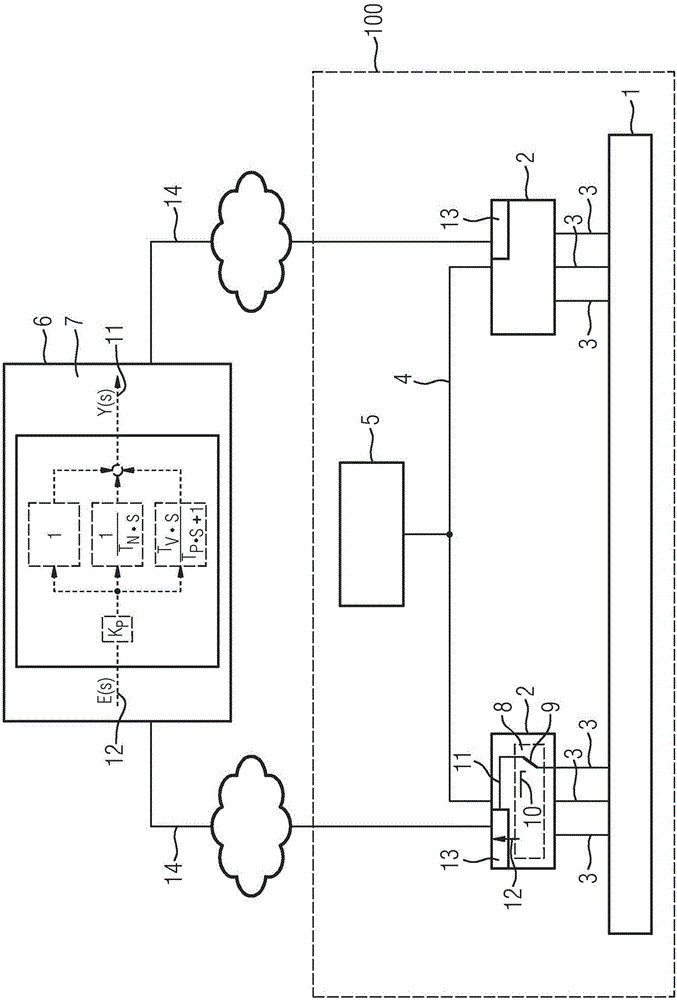

[0017] figure 1 A system 100 is shown for controlling an industrial process 1 , for example a process for water treatment in a purification plant or a process for conveying liquids or gases through pipelines. The process 1 is controlled and regulated via a decentralized plant-side automation unit 2 which for this purpose has an on-site connection to the process. figure 1 A series of operative connections 3 of sensors and actuators not shown in detail. Two automation units 2 are shown by way of example, in reality there are many more which control, regulate and monitor the process. The automation unit 2 is connected via a first data connection 4 to a monitoring system 5 which controls and monitors the process 1 . The automation unit 2 performs monitoring and regulating functions 8 acting on the process. In this configuration, the system 100 is efficient and able to fulfill its control, regulation and monitoring tasks. The system 100 is expanded by a computing unit 6 outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com