Optimized design method for trimming centrifugal pump impeller cover plate

A centrifugal pump impeller, optimized design technology, applied in the field of centrifugal pump research, can solve the problems affecting the working environment and overall performance, the low vibration and low noise design of the centrifugal pump is not paid enough attention, and only pays attention to the efficiency, cost and life of the centrifugal pump. Reduce the effect of severe pressure pulsation, stabilize the flow, and reduce the effect of vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

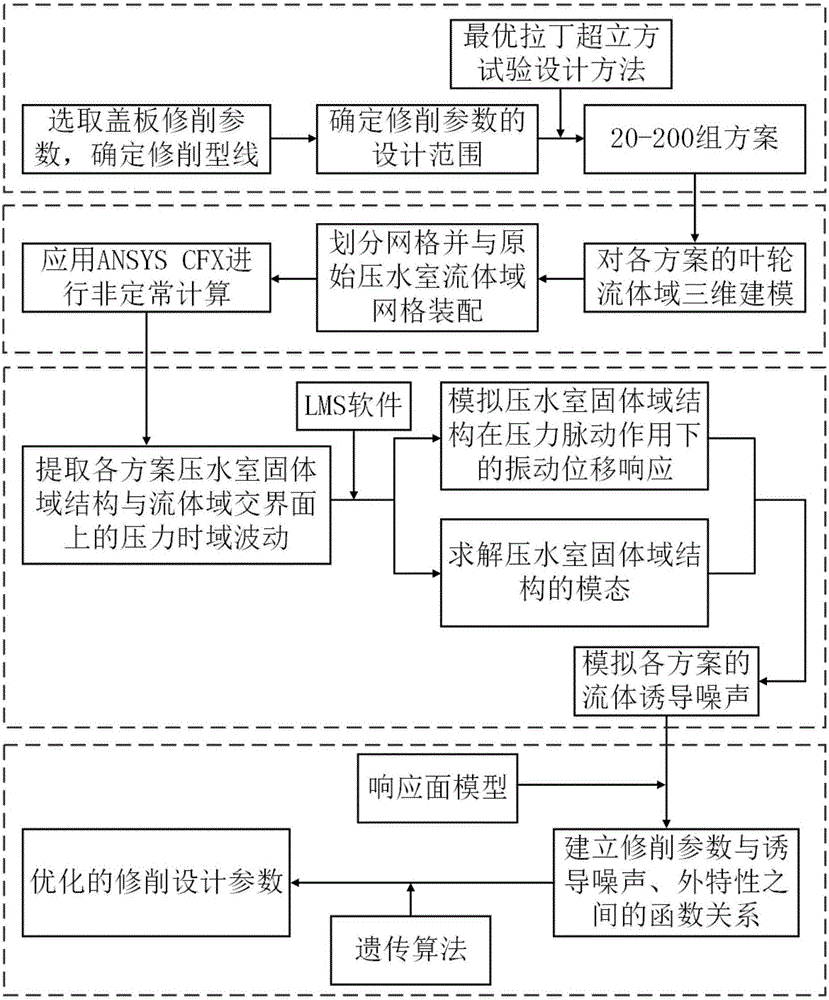

[0025] figure 1 Shown is an embodiment of the optimal design method for trimming the impeller cover plate of the centrifugal pump according to the present invention, and the optimal design method for trimming the impeller cover plate of the centrifugal pump includes the following steps:

[0026] S1. Select the trimming parameters of the impeller cover plate of the centrifugal pump, and determine the design range of the trimming parameters, and design 20 to 200 groups of trimming schemes by using the optimal Latin hypercube test design method;

[0027] S2. Carry out three-dimensional modeling of the impeller basin of each group of schemes, divide the grid and assemble it with the fluid domain grid of the original pressurized water chamber, use ANSYS CFX software to perform steady and unsteady calculations, and obtain the external characteristics of each scheme through the steady calculation;

[0028] S3. Extract the pressure time-domain fluctuations on the interface between the...

Embodiment

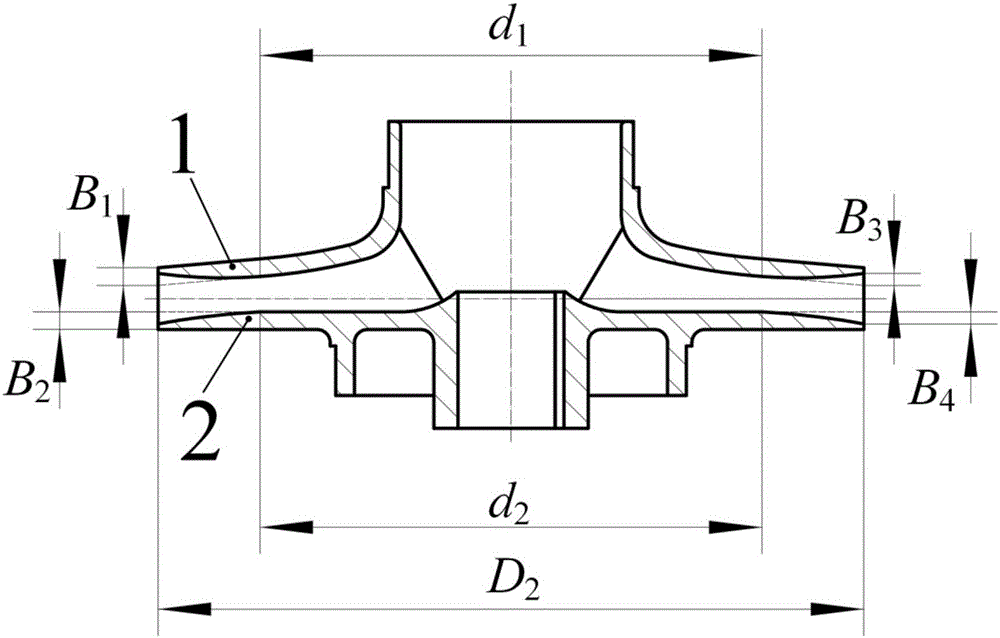

[0033] Taking a low specific speed centrifugal pump IS50-32-160 as an example, the design flow of the pump is 6.3m 3 / h, pump impeller outlet diameter D 2 = 160mm, design head H = 8m, efficiency η = 65%, the thickness of the outlet of the front cover is equal to the thickness of the outlet of the rear cover, namely B 1 =B 2 = 4 mm. When the pump was working under the design conditions, severe vibration and noise were produced, so the design method of the present invention was adopted to improve it, and the design steps were as follows:

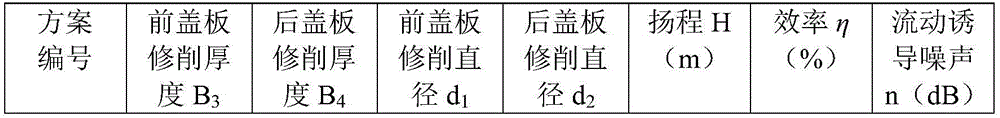

[0034] S1. Select the trimming thickness of the front cover B 3 , Rear cover trimming thickness B 4 , Front cover trimming diameter d 1 , Rear cover trimming diameter d 2 , and determine the design range of trimming parameters, respectively (0, 2], (0, 2], [80, 160), [80, 160), using the optimal Latin hypercube experiment design method, to obtain 25 groups of designs Program;

[0035] S2. Carry out three-dimensional modeling of the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com