A Model Adaptive Illumination Homogenization Method for Face-to-face Exposure 3D Printing

A model self-adaptive and 3D printing technology, which is applied in the fields of intelligent control and image recognition, can solve the problems affecting the precision of parts, differences in resin curing, and small exposure surface, etc., to achieve improved exposure time, high printing success rate, and high exposure The effect of time enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

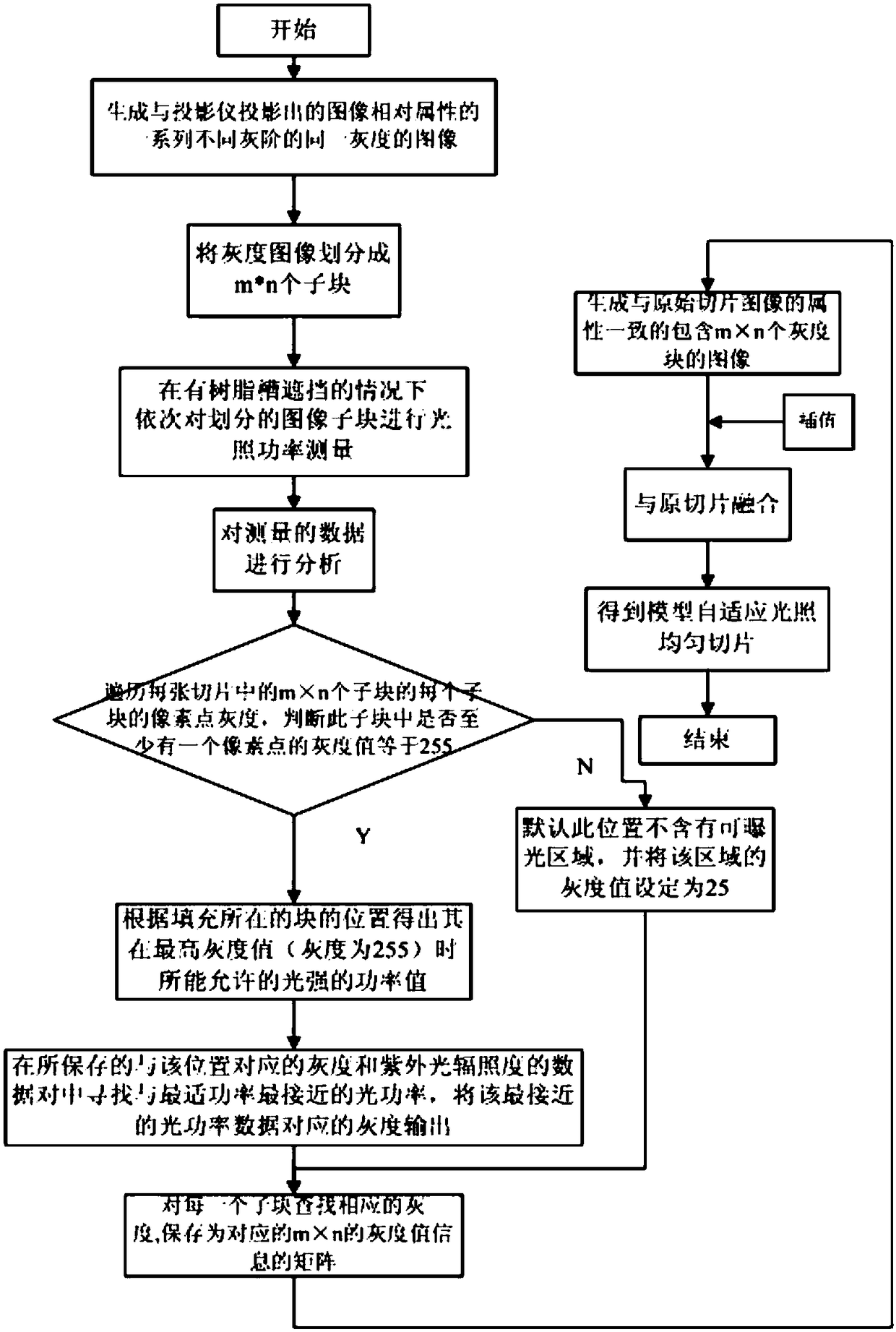

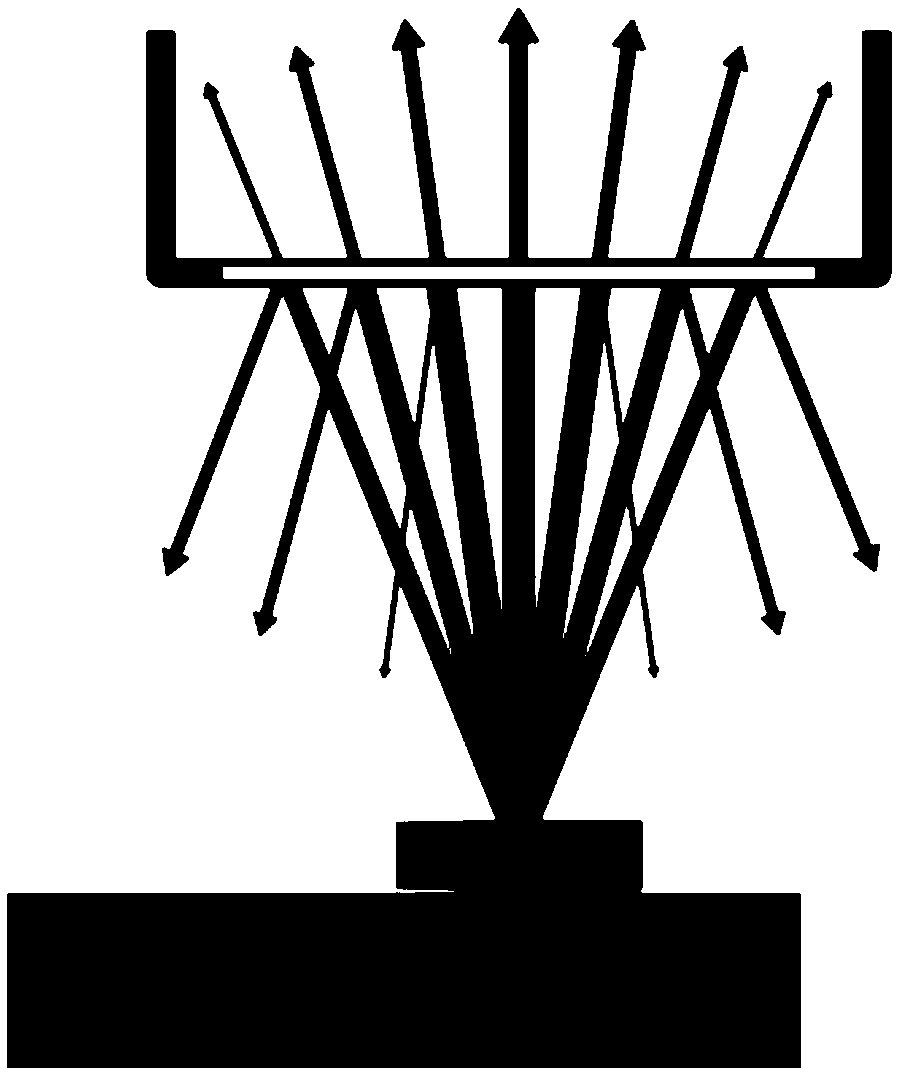

[0039]The invention provides a model adaptive illumination homogenization method for surface exposure 3D printing, which can realize adaptive adjustment of the gray scale of each slice, so as to achieve uniform distribution of ultraviolet light irradiance in the view generation plane , providing the possibility for subsequent large-area exposure.

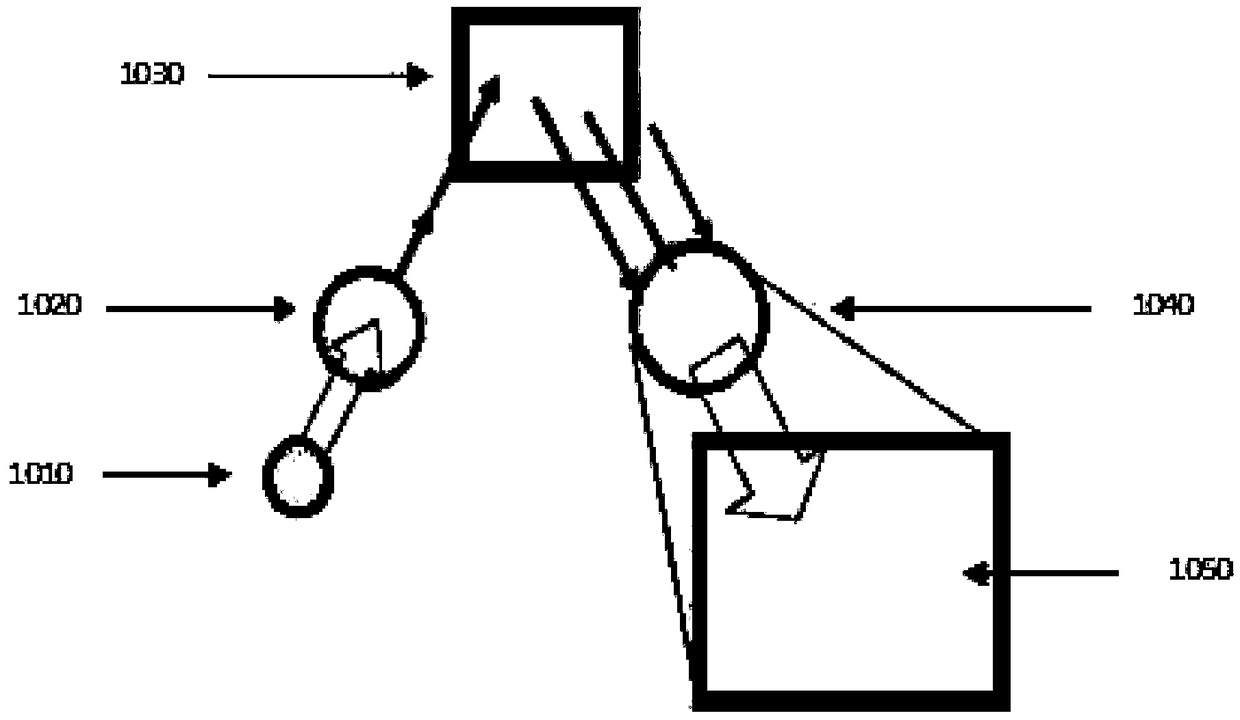

[0040] Surface exposure 3D printers mainly use a projector as a light source, and the most important thing in a projector is a digital micromirror device (DMD) to complete the technology of visual digital information display. Specifically, the digital light processing (DLP) projection technology uses a digital micromirror chip (DMD) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com