An Electron Beam Exposure Method for Improving the Uniformity of Grating Structure

A technology of grating structure and uniformity, which is applied in microlithography exposure equipment, diffraction gratings, photolithographic process exposure devices, etc., can solve problems such as electron scattering and superposition, and achieve the effect of improving exposure uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

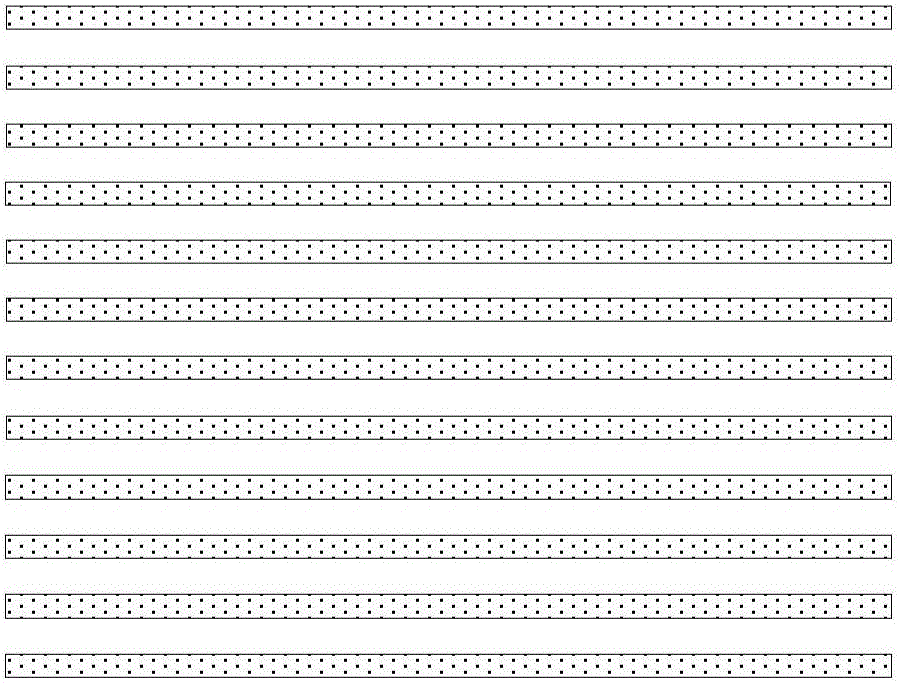

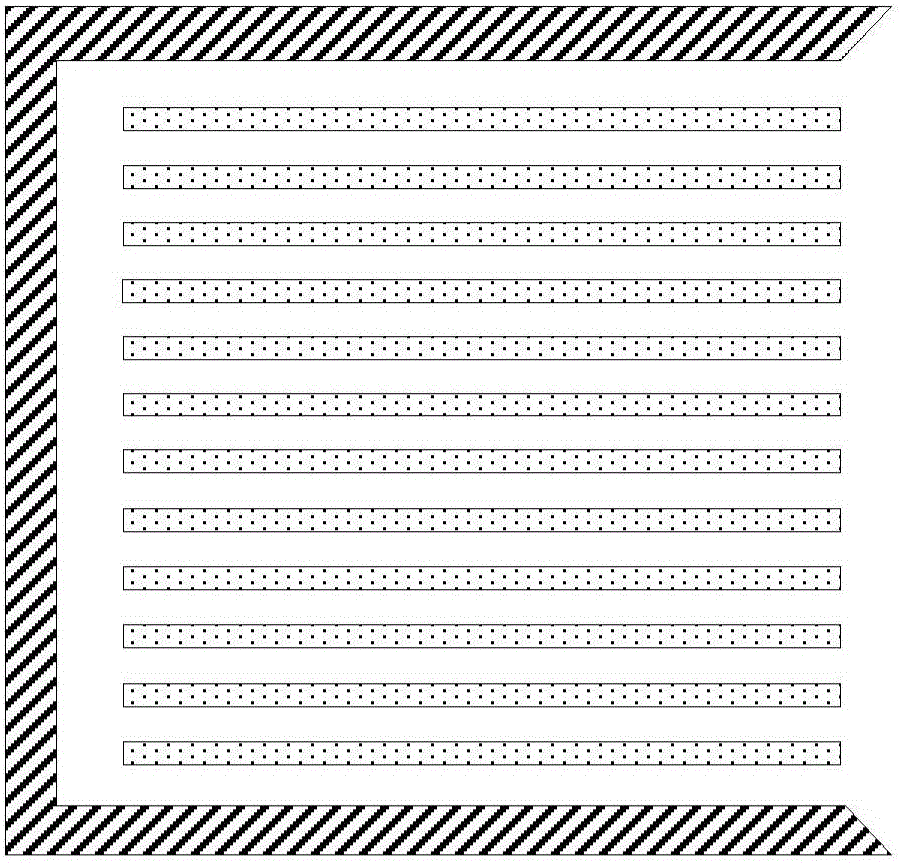

[0021] The method for improving the exposure uniformity of the grating provided by the present invention arranges trapezoidal compensation patterns around the original nanoscale grating, which reduces the influence of the proximity effect on the pattern, so that each grating bar is not deformed and superimposed. The nanoscale gratings are densely arranged in submicron order period, and the edges of the pattern are smooth.

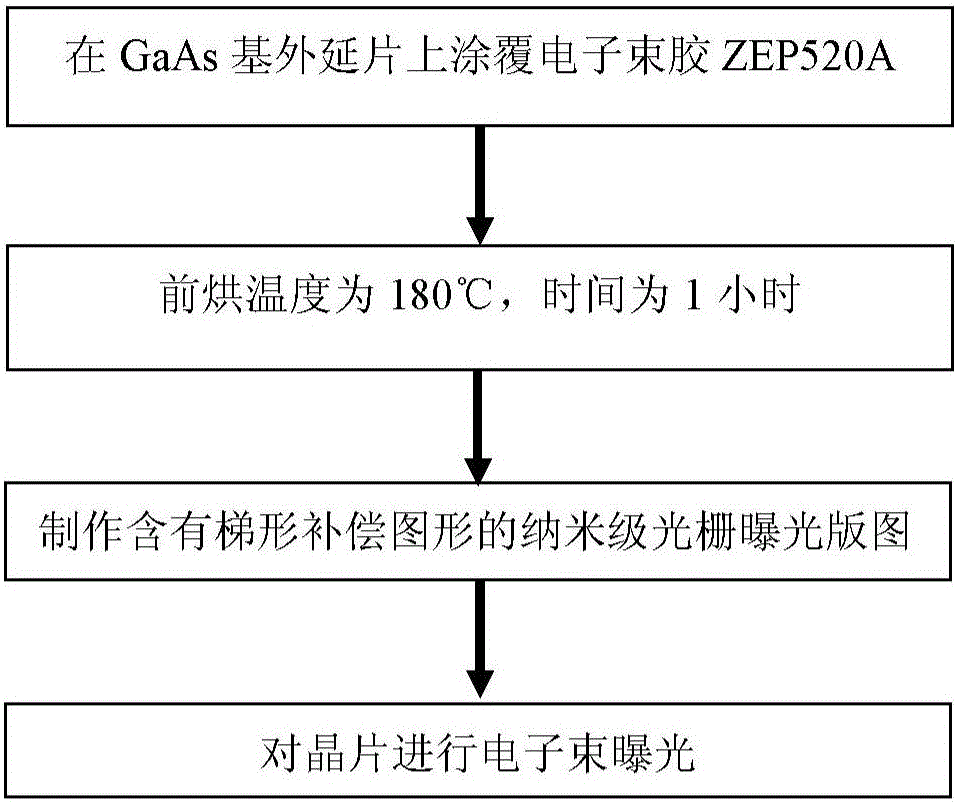

[0022] figure 1 A flow chart of an electron beam exposure method for improving grating exposure uniformity according to an embodiment of the present invention is shown. Such as figure 1 As shown, this embodiment takes a GaAs-based epitaxial wafer as an example, and the method includes the following s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com