Main power controller assembly

A technology of controller and main power supply, which is applied in the direction of circuits, electrical components, electrical equipment casings/cabinets/drawers, etc., which can solve the problems of time-consuming maintenance and replacement, waste of stalls, and large space occupation, and achieve low production and maintenance costs. Ease of selection and use, and reduced footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

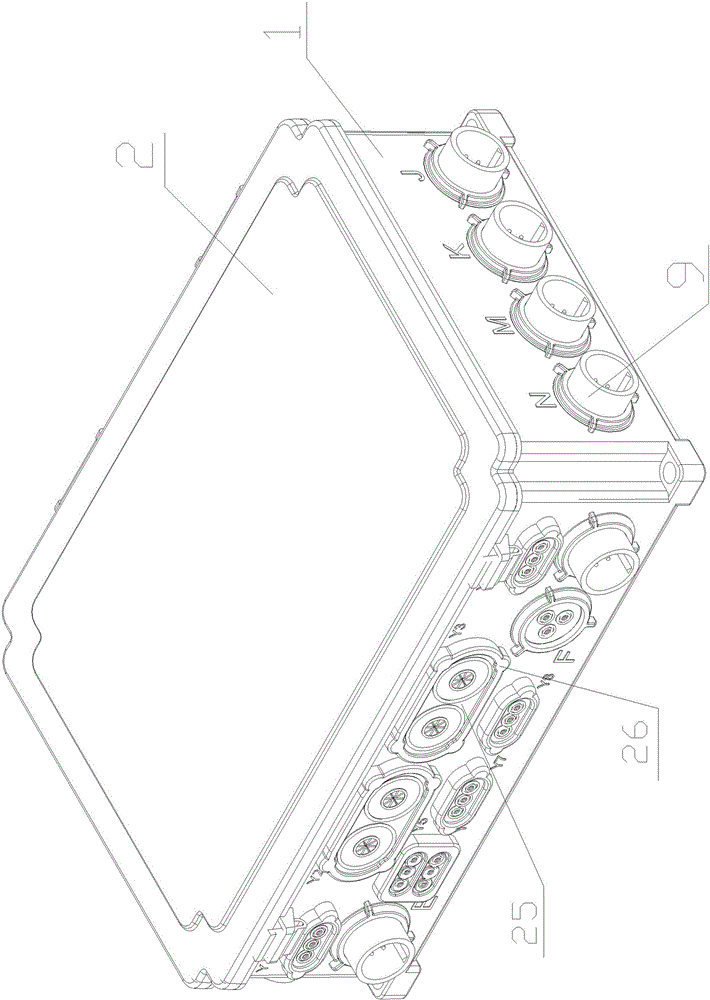

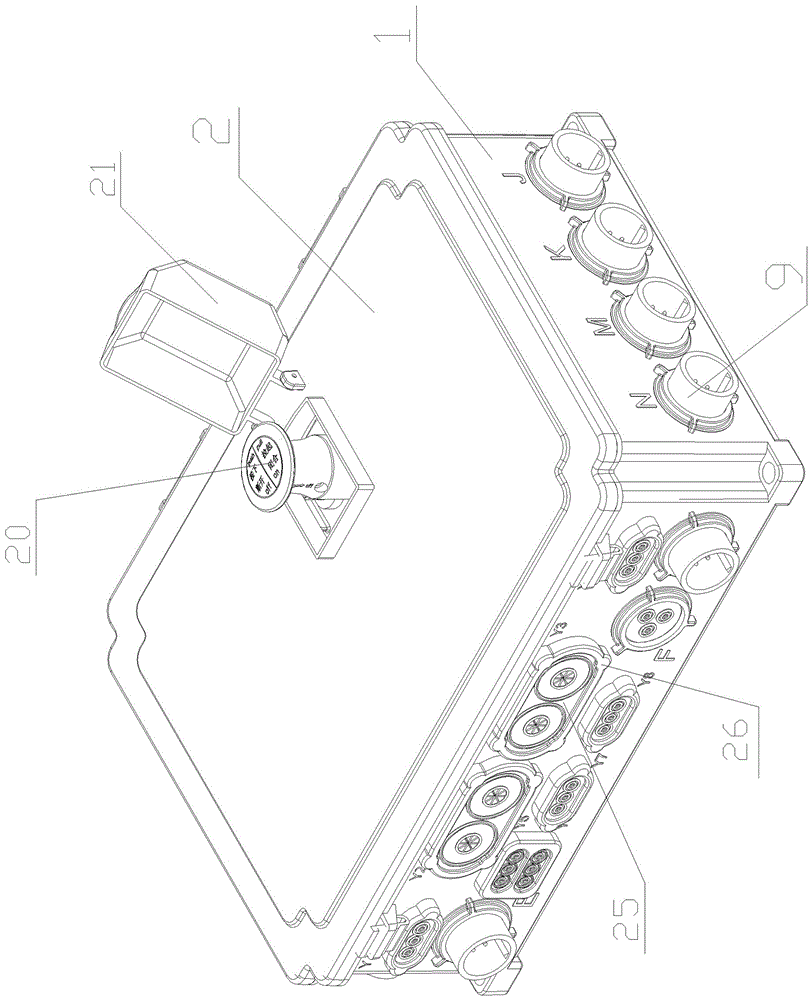

[0039] Embodiment 1: A main power controller assembly, including a box body 1 and a box cover 2. A control circuit board 3 is installed on the inner bottom of the box body 2. The control circuit board 3 can be installed on both sides of the bottom of the box body close to The position of its side wall. The control circuit board 3 is connected to the external wiring harness through the elbow plug-in 4; the elbow plug-in 4 includes a plug-in box and a set of pins 5 arranged in the plug-in box. The outlet end of the plug-in box and the inlet end form a 90-degree spatial angle , The pins 5 are distributed in a circular honeycomb array at the outlet end, and are distributed in a matrix at the inlet end. The pins 5 pass through the inside of the plug-in box and have at least one bend inside to meet the distribution mode; The plug-in box is provided with an insulating partition for isolating each pin and a slot for installing and positioning each pin; a plug-in installation hole 6 is ...

Embodiment 2

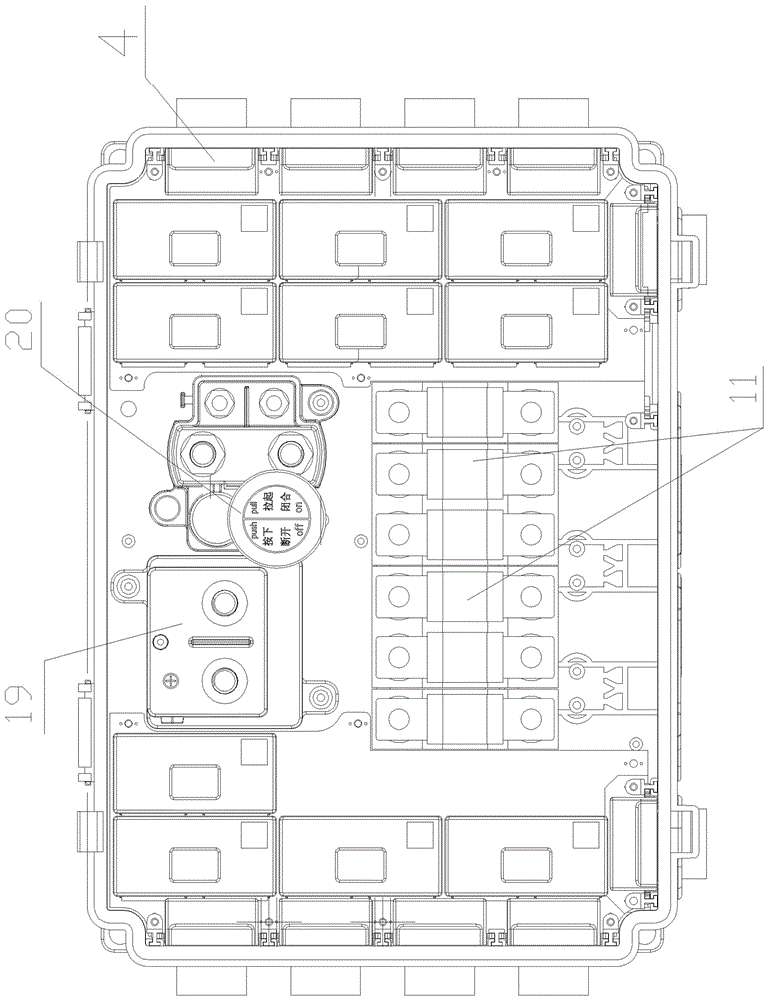

[0043] Embodiment 2: A main power controller assembly. On the basis of Embodiment 1, a high-power fuse assembly is also installed in the box 1. The high-power fuse assembly includes at least one independent fuse holder 10 and Corresponding to the fuse 11 installed on the fuse holder 10; the fuse holder includes a main body, and a pair of fixing bolts 13 symmetrically arranged on the main body, and the fixing bolts on each fuse holder 10 are at least one pair. A heat dissipation round table 14 is provided at the lower part of each fixing bolt 11, and the heat dissipation round table 14 is preferably a copper platform; at least one mounting limiter 12 is provided on the bottom surface of the main body, and a mounting limiter 12 is provided on the bottom plate of the box body 1. Piece 12 matching limit slot. The high-power fuse assembly also includes a spacer block 15 for elevating the fuse holder. A limit groove matching the installation limit member 12 at the bottom of the main ...

Embodiment 3

[0044] Embodiment 3: A main power controller assembly. On the basis of embodiment 2, the high-power fuse assembly further includes an overheating fuse alarm device, and the overheating fuse alarm device includes a heat conduction device for pressing and fixing on a fixing bolt Sheet 16, and correspondingly connected to the thermal conductive sheet 16, and arranged on the side wall of the fuse holder overheating alarm circuit board 17, on the overheating alarm circuit board 17 is provided with an overheating alarm circuit and alarm indicator 18, see Figure 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com