Small gap non-binding electrostatic sealing process for sensor

A small gap, sensor technology, applied in the direction of circuits, relays, electric switches, etc., can solve problems such as adhesion, achieve high connection strength, reliable long-term stability, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

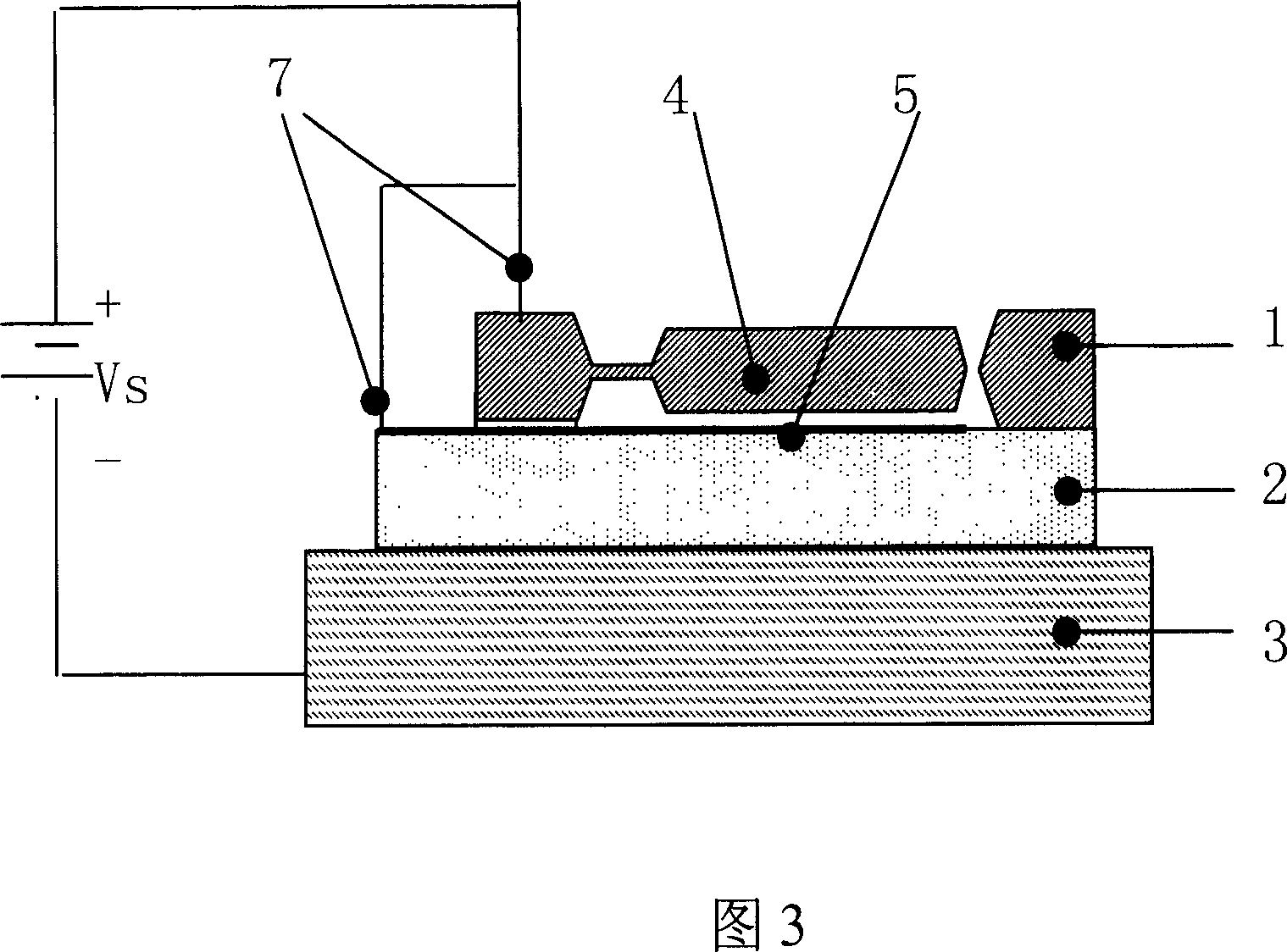

[0021] Embodiment 3, as shown in Figure 6: in this example, each part is arranged in the order of 1-3 as example 1, and the power connection method is also the same as the above-mentioned example 1, and it is characterized in that the perforated glass 2 ` adopts Structure, in order to make the electrode layer 5 located in the middle of the porous glass 2' connect to the negative electrode, add a spacer 6 between the porous glass 2' and the heating plate 3, so that there is a gap between 2' and 3 to introduce the potential Line 7 is exported. The conductive spacer 6 is made of conductive material, such as metal or silicon. The porous glass 2' is connected to the negative electrode through the heating plate 3 and the spacer 6. Fig. 7 shows the top view of perforated glass 2 ' in example 3; It is characterized in that perforated glass 2 ' has a hole in the center of the plane, and there are metal electrode layers 5 formed by sputtering process on the upper and lower sides, and t...

Embodiment 4

[0022] Embodiment 4 As shown in FIG. 8, the sequence of parts and power connection are the same as the above-mentioned Example 3, but the film area of the silicon chip 1 can be on the surface of the device, such as piezoresistive acceleration sensors and capacitive acceleration sensors.

[0023] The metal electrode layer 5 is fabricated on the surface of the glass or perforated glass by sputtering process, and then the electrode layer is processed into the electrode connection line 8 connected with the edge pads by the photoetching process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com