Automatic pneumatic-conveying feeding system for deep sea cage culture

A technology for automatic feeding and deep-sea cages, applied in the field of aquaculture machinery, can solve the problems of uneven feeding, low feeding efficiency, poor adaptability to the environment, etc., and achieve the effects of improving conveying efficiency, improving feeding efficiency and reducing gas leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

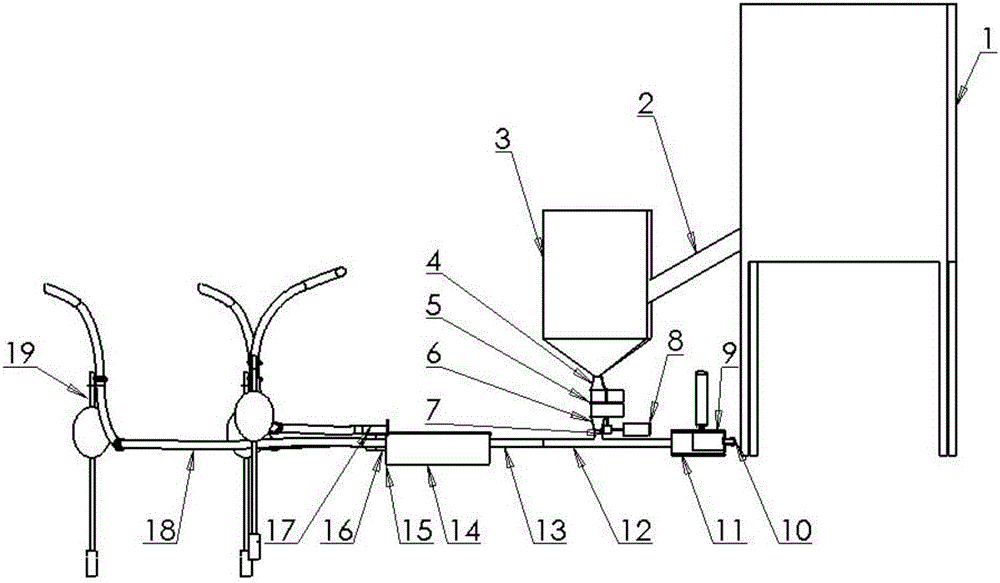

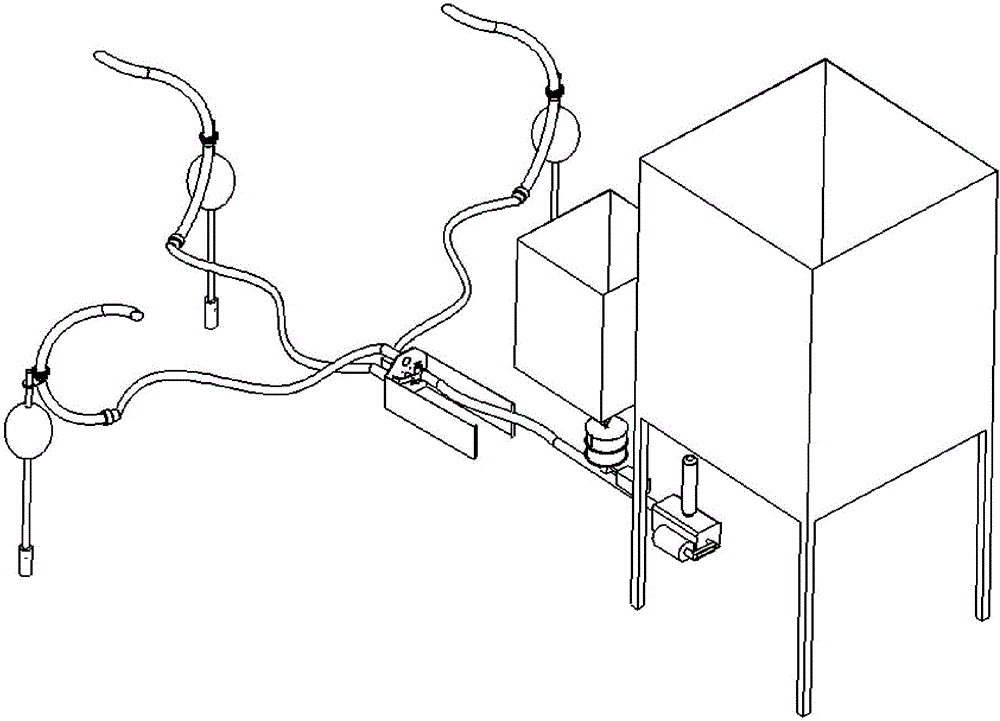

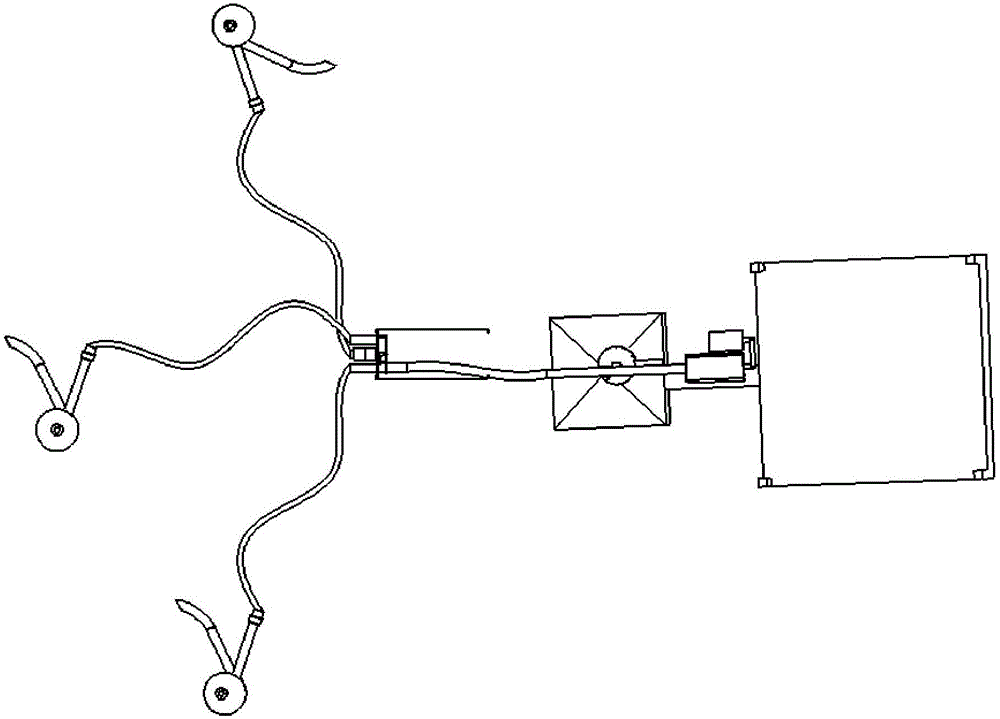

[0031] Such as figure 1 , figure 2 , image 3 As shown, a deep-sea net cage cultivation air feeding automatic feeding system includes an air feeding mechanism, a feeding mechanism, a pipeline distributor 14, and a feeder 19; the air feeding mechanism includes a Roots blower 11, a fan drive motor 9 and a front steel pipe 12. The Roots blower 11 and the blower drive motor 9 are connected through a transmission belt 10, the transmission belt 10 is a V-shaped transmission belt, and a transmission belt tensioner is provided. The air outlet of Roots blower 11 is connected with the front steel pipe 12, which is used to convey the pressure air into the pipeline; the unloading mechanism includes a large material box 1, a small material box 3 and a feeder 5, a large material box 1 and a small material box 3 are connected through the inclined material pipe 2, the horizontal position of the large material box 1 is higher than that of the small material box 3, and the angle between the ...

Embodiment 2

[0036] The principle is the same as in Embodiment 1, and the Roots blower 11 can be replaced with a pump body such as a compressed air pump that delivers positive pressure air. The feeder can use external groove wheel feeder, screw feeder and other feeders. The end spreader can be changed to other floating system to make the spreading rotating tube float on the water surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com