Bamboo barrel Jinhua Fuzhuan tea and processing method thereof

A processing method and technology of bamboo tube, applied in the field of bamboo tube Jinhua Fu tea and its processing, can solve the problems of lack of innovative design and structure, unable to meet the new demand of market consumption, etc., to achieve convenient ventilation, exquisite appearance, and unique bamboo fragrance and mellow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

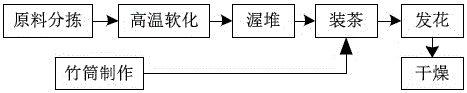

[0065] A method for processing golden flower tea in a bamboo tube is characterized in that it comprises the following processing steps: sieving raw materials, softening at high temperature, stacking, packing into tubes, blooming and drying.

[0066] Further, the processing steps operate in the following manner:

[0067] 1) Screening of raw materials: According to the product grade, different grades of black hair tea are selected for blending, and the sundries in the tea leaves are removed to obtain optimal tea leaves;

[0068] 2) High temperature softening: according to the water content of the tea leaves in step 1), add an appropriate amount of water and mix well, control the water content of the tea leaves after mixing well to 25-30%, and use steam at 110-160°C to reduce the water content to 25% Steam 30% of the optimal tea leaves for 3-5 minutes to fully soften the optimal tea leaves and remove the clear water on the surface of the tea leaves to obtain softened tea leaves; ...

Embodiment 2

[0077] A processing method of golden flower tea in a bamboo tube is characterized in that it also includes the following steps and operation methods:

[0078] 1) Screening of raw materials: According to the product grade, different grades of black hair tea are selected for blending, and the sundries in the tea leaves are removed to obtain optimal tea leaves;

[0079] 2) High temperature softening: according to the water content of the tea leaves in step 1), add an appropriate amount of water and mix well, control the water content of the tea leaves after mixing well to 25-30%, and use steam at 110-160°C to reduce the water content to 25% Steam 30% of the optimal tea leaves for 3-5 minutes to fully soften the optimal tea leaves and remove the clear water on the surface of the tea leaves to obtain softened tea leaves;

[0080] 3) Inducing flowering: spread the softened tea leaves in step 2) evenly, cool naturally to room temperature, grind the loose tea leaves with good flowerin...

Embodiment 3

[0089] A processing method of golden flower tea in a bamboo tube is characterized in that it also includes the following steps and operation methods:

[0090] 1) Screening of raw materials: According to the product grade, different grades of black hair tea are selected for blending, and the sundries in the tea leaves are removed to obtain optimal tea leaves;

[0091] 2) High temperature softening: according to the water content of the tea leaves in step 1), add an appropriate amount of water and mix well, control the water content of the tea leaves after mixing well to 25-30%, and use steam at 110-160°C to reduce the water content to 25% Steam 30% of the optimal tea leaves for 3-5 minutes to fully soften the optimal tea leaves and remove the clear water on the surface of the tea leaves to obtain softened tea leaves;

[0092] 3) Inoculum: Spread the softened tea leaves in step 2) evenly, cool naturally to room temperature, spray the suspension containing the spores of S. corono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com