A kind of toothbrush and its manufacturing process

A technology of toothbrush and bristles, applied in the field of toothbrush and its manufacturing process, can solve the problem of low efficacy of toothbrush and toothpaste, and achieve the effect of simple structure and improved polishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

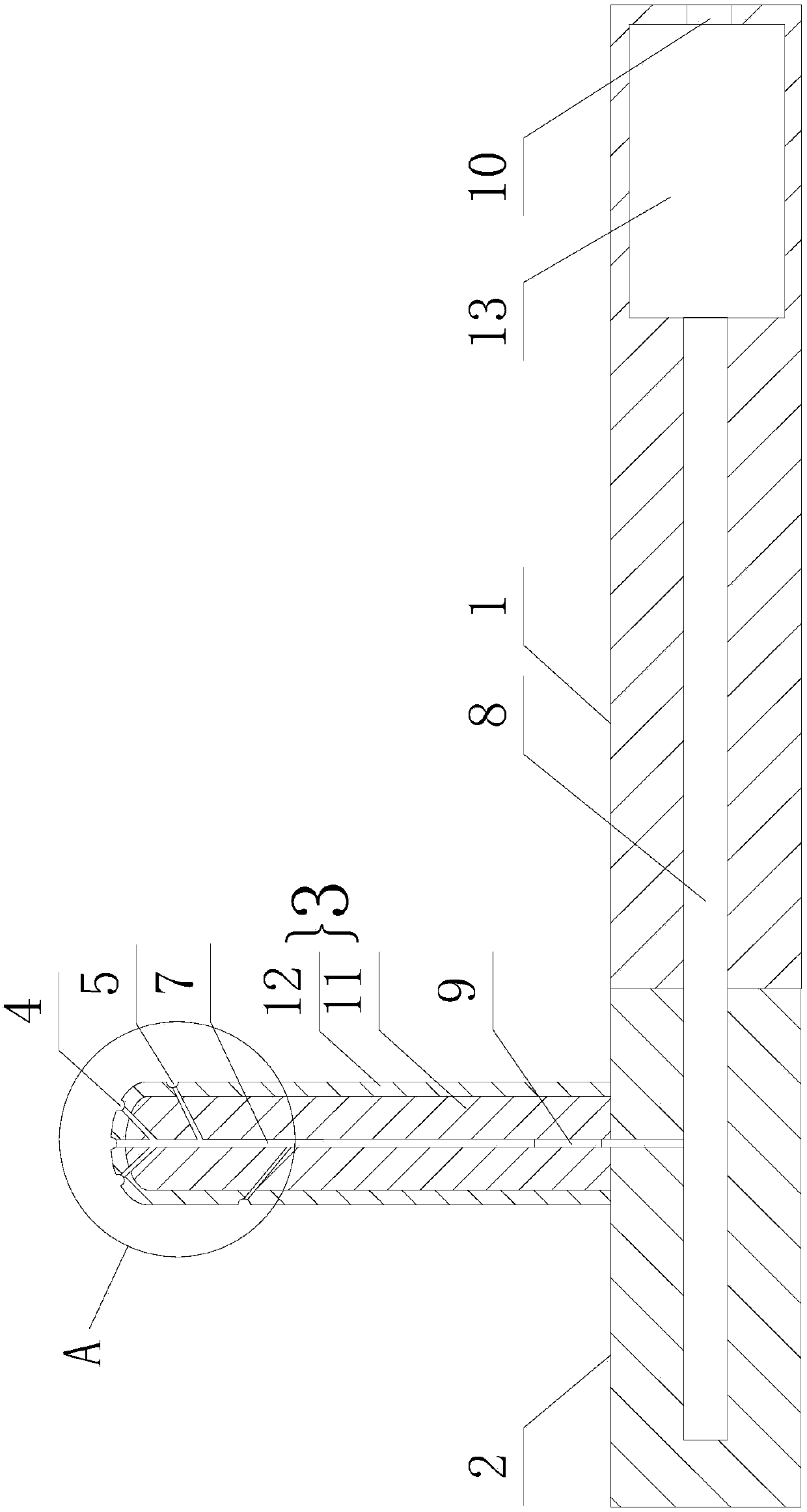

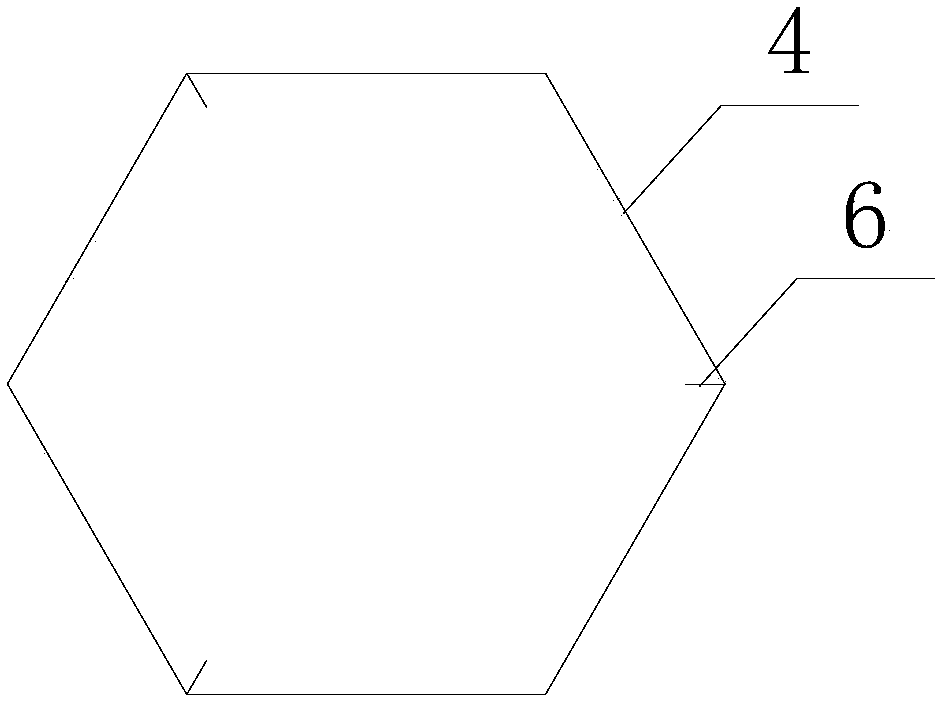

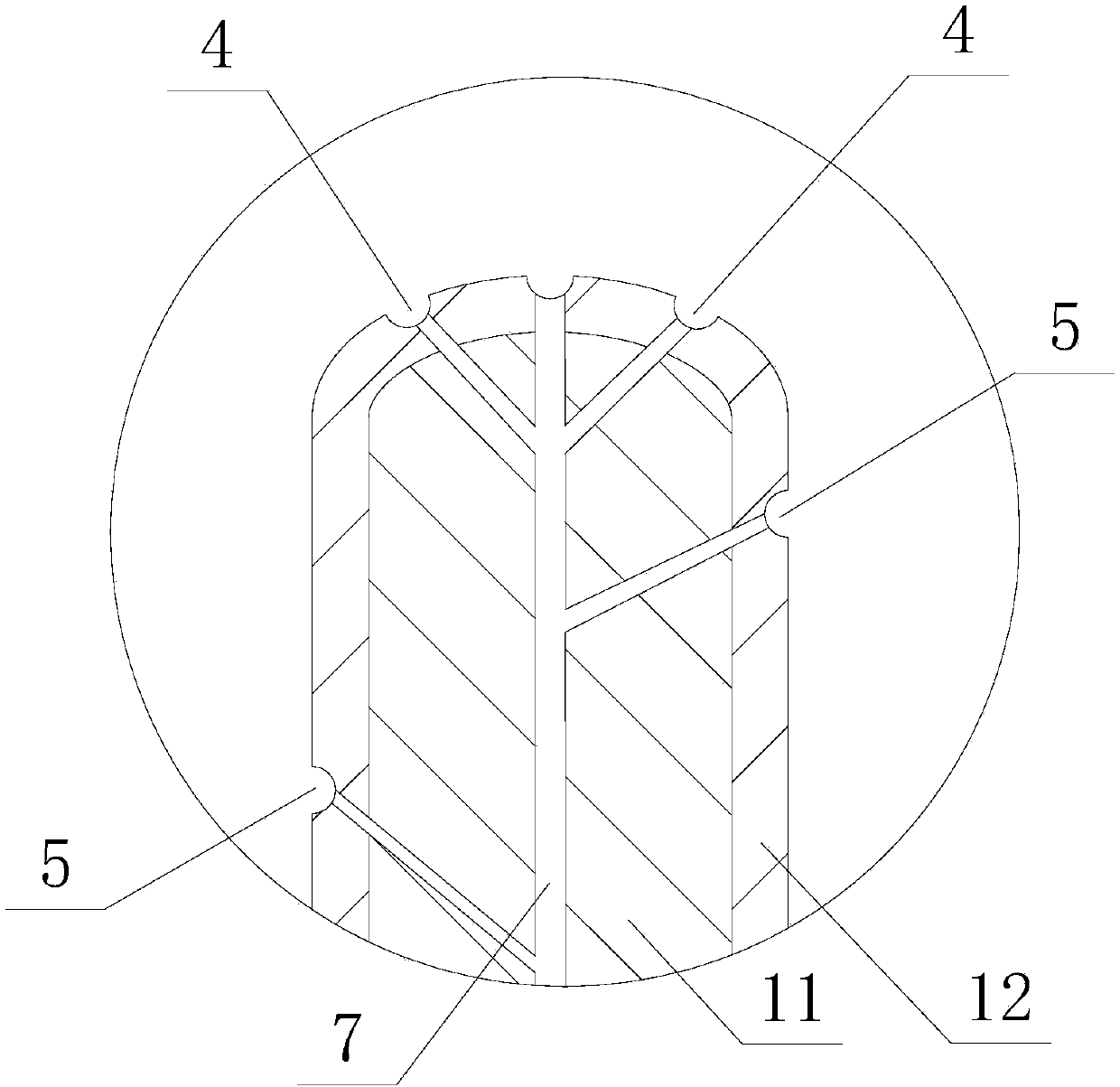

[0018] refer to figure 1 , figure 2 , image 3 It is an embodiment of a toothbrush and its manufacturing process of the present invention. In order to show the structure of the bristle clearly, the size of the bristle is enlarged in the figure. A toothbrush includes a brush handle 1, a brush head 2 and a bristle 3, and the bristle The top of the 3 is provided with a top clamping hole 4 for clamping a single toothpaste abrasive, and along the side wall of the bristle 3 is provided with a side clamping hole 5 for clamping a single toothpaste abrasive, and the side clamping holes 5 are arranged from bottom to top along the side wall of the bristle 3. A gradually rising curve, with the length of the bristles as the X-axis of the curve, the circumference of the bristles after expansion as the Y-axis, the projection of the curve in the vertical plane is a tangent curve or a sinusoidal curve, and two adjacent side clamping holes 5 The straight-line distance of the projection in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com