Automobile tractor bracket punching die

A tractor and punching technology, which is applied in the field of punching molds for automobile tractor brackets, can solve the problems of punch breakage, small thick holes, and large production volume, and achieve the effects of reasonable structure, prolonging service life, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

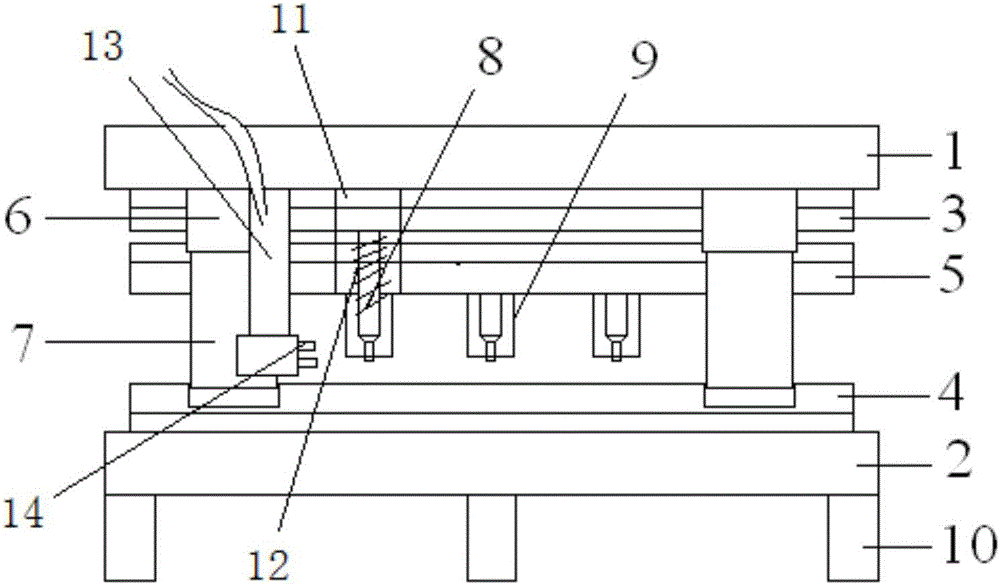

[0012] see figure 1 , a punching die for an automobile tractor bracket, comprising upper and lower mold bases 1 and 2, an upper template 3 is fixedly installed on the inner side of the upper mold base 1, a lower template 4 is fixedly installed on the lower mold base 2, and an upper mold base 4 is fixedly installed on the inner side of the upper mold base 1 A binder plate 5 is fixedly installed on the inner side of the formwork 3, guide sleeves 6 are respectively provided on both sides of the inner surface of the upper formwork 3, guide posts 7 are fixedly installed on both sides of the upper surface of the lower formwork 4, and the guide posts 7 are nested Slide up and down in the guide sleeve 6 and along the inner wall of the guide sleeve 6; three punches 8 are respectively installed on the inner surface of the upper template 3, and a sheath 9 is respectively arranged around the outer side of each punch, and the punches 8 Tail is provided with guide groove 11, and described g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com