Hydraulic control system for ship traction winch, transmission device and control method

A hydraulic control system and a towing winch technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems such as the difficulty of completing the recovery operation smoothly, the deployment of the cable tension load, etc., to improve the work ability, improve work efficiency, reduce The effect of small tension changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

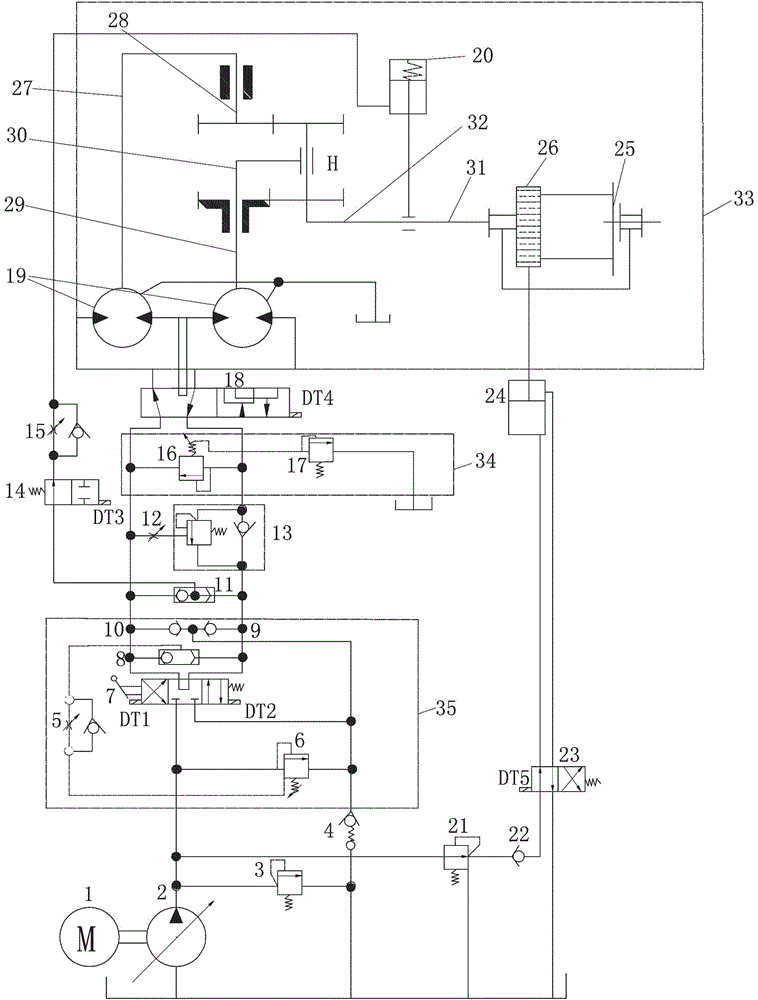

[0039] Further, adopt the marine towing winch transmission device controlled by the hydraulic system, it comprises two-way hydraulic motor 19, wherein the output shaft of one two-way hydraulic motor 19 is connected with the first sun gear 28 through the first coupling 27; The output shaft of the hydraulic motor 19 is connected with the second sun gear 30 through the second coupling 29, and the second sun gear 30 is engaged with the planetary gear 32 for transmission, and the planetary gear 32 is decelerated with the planetary gear through the third coupling 31 The motor 26 is connected, and the output shaft of the planetary reducer 26 is connected with the rotating shaft of the reel 25 to transmit torque.

[0040] Further, in the marine towing winch transmission device, the third coupling 31 is connected with a brake cylinder 20, and the brake cylinder 20 is connected to The second shuttle valve 11 is connected.

[0041] Further, the marine towing winch transmission device, t...

Embodiment 3

[0043] The method for controlling the transmission device of a marine towing winch using the hydraulic control system comprises the following steps:

[0044] In the first step, the hydraulic winch puts the heavy object in the normal operation mode. Once the heavy object is lowered into the water, the pressure setting level is reduced through the adjustable pressure valve 17. In this mode, when the load on the hydraulic winch is higher than the pressure When setting the level, the cable is in the state of unwinding, and when the load of the winch is less than the pressure setting, the cable is retracted;

[0045] In the second step, when the system is in the deployment condition, the DT2 of the three-position four-way reversing valve 7 is energized, the hydraulic motor 19 rotates forward, and the reel 25 is driven forward by the planetary reducer 26 to rotate forward, and the load can be put down;

[0046] In the third step, when the system is in the deploying condition, DT1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com