Bidiindoledione d-a-d type polymer electrochromic material and preparation method thereof

An electrochromic material, D-A-D technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of increasing the difficulty of polymerization and restricting the development of polymers in the field of electrochromism, achieving a wide light absorption range and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

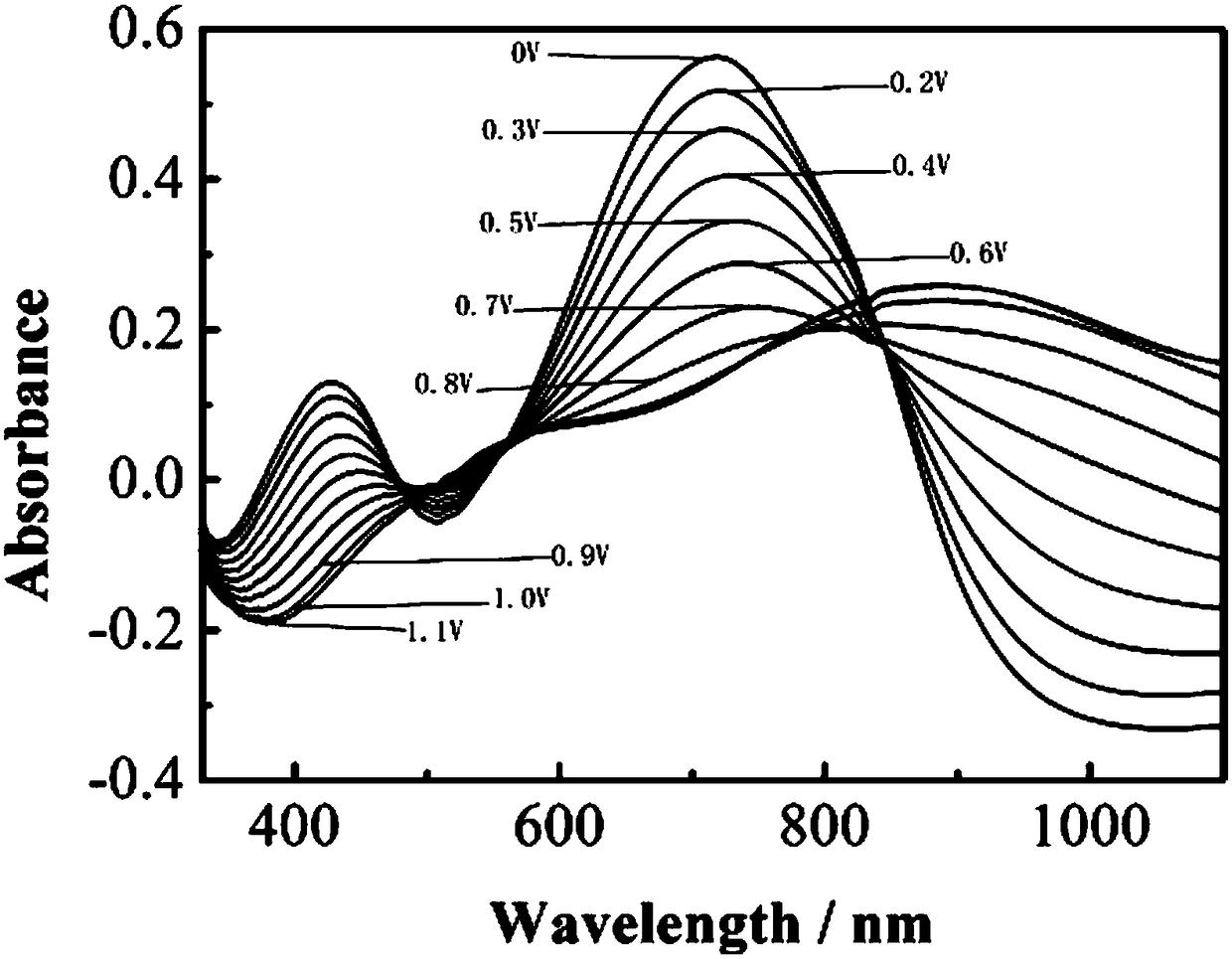

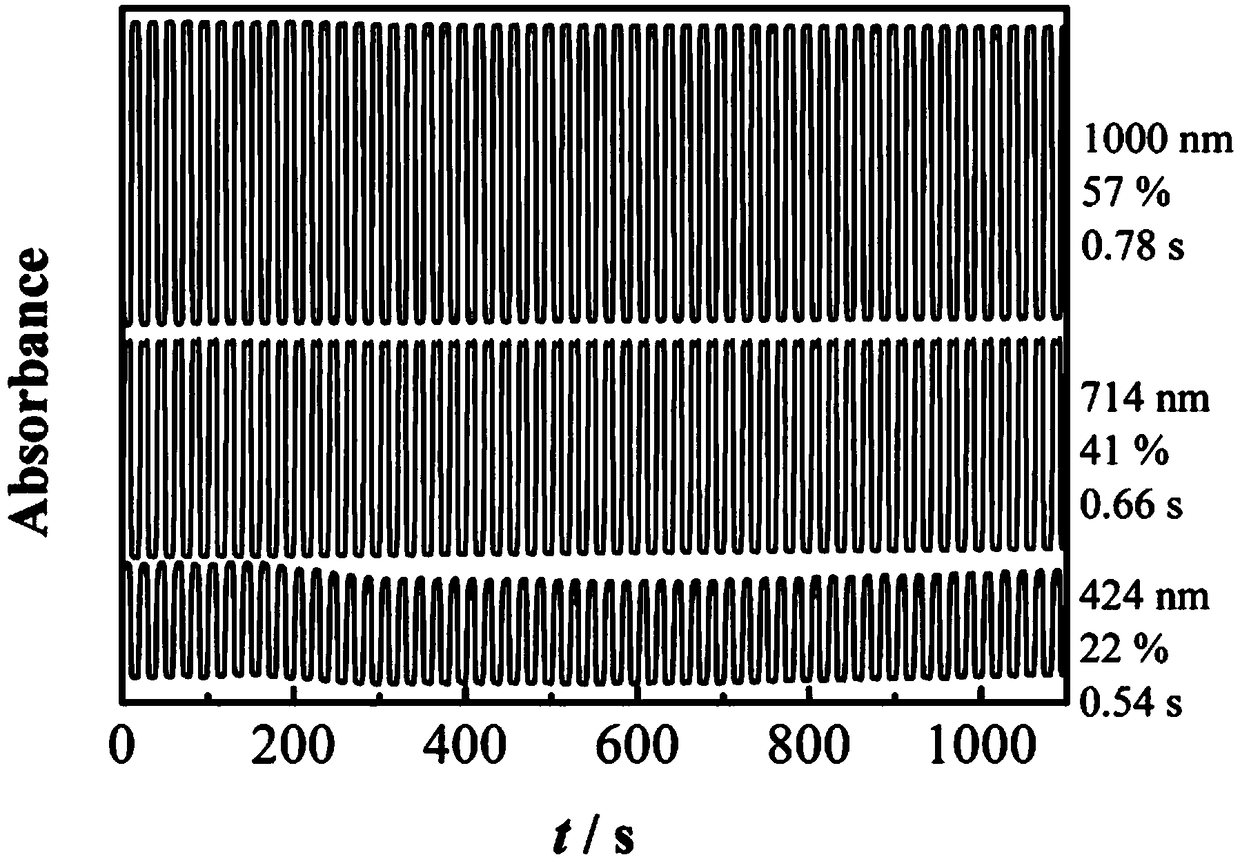

[0059] Embodiment 1: the electrochemical synthesis of P (IDOH-EDOT) polymer electrochromic material

[0060] (1) Synthesis of IDOH-EDOT active precursor

[0061]

[0062] Under the condition of nitrogen protection, add a certain proportion of 6,6'-dibromo-3,3'-dihexylindoledione, 2-tinbutyl-3,4-ethane into a three-necked flask filled with toluene solvent Dioxythiophene, in catalyst Pd(PPh 3 ) 4 Under catalysis, it was condensed and refluxed at 110°C for 12 hours; after the reaction, the product was extracted three times with chloroform, dried with a small amount of anhydrous magnesium sulfate for 24 hours, and then the solvent was distilled off under reduced pressure, separated by silica gel chromatography, and purified to obtain a purple-red solid product , the yield was 80%. 1 HNMR (CDCl 3 ): δ9.14(d,J=8.47Hz,2H),7.35–7.33(dd,J 1 =8.4Hz, J2=1.6Hz, 2H), 7.22(s, 2H), 6.39(s, 2H), 4.36–4.28(m, 8H), 3.82–3.79(m, 4H), 1.65-1.55(m, 4H), 1.43–1.24(m,12H), 0.98–0.86(m,6H). ...

Embodiment 2

[0073] Embodiment 2: the electrochemical synthesis of P (IDOD-EDOT) polymer electrochromic material

[0074] (1) Synthesis of IDOD-EDOT active precursor

[0075]

[0076] Under the condition of nitrogen protection, a certain proportion of 6,6'-dibromo-3,3'-bidocosindoledione, 2-tinbutyl-3,4 -Ethylenedioxythiophene, in catalyst Pd(PPh 3 ) 4 Under catalysis, it was condensed and refluxed at 110°C for 12 hours; after the reaction, the product was extracted three times with chloroform, dried with a small amount of anhydrous magnesium sulfate for 24 hours, and then the solvent was distilled off under reduced pressure, separated by silica gel chromatography, and purified to obtain a purple-red solid product , the yield was 88%. 1 HNMR (CDCl 3 ): δ9.01(d,J=8.47Hz,2H),7.35–7.33(dd,J 1 =8.4Hz,J 2 =1.6Hz,2H),7.22(s,2H),6.39(s,2H),4.36–4.28(m,8H),3.8–3.7(m,4H),1.65-1.55(m,4H),1.43– 1.24(m,36H),0.98–0.86(m,6H).

[0077] (2) Electrochemical polymerization of P(IDOD-EDOT) polymer...

Embodiment 3

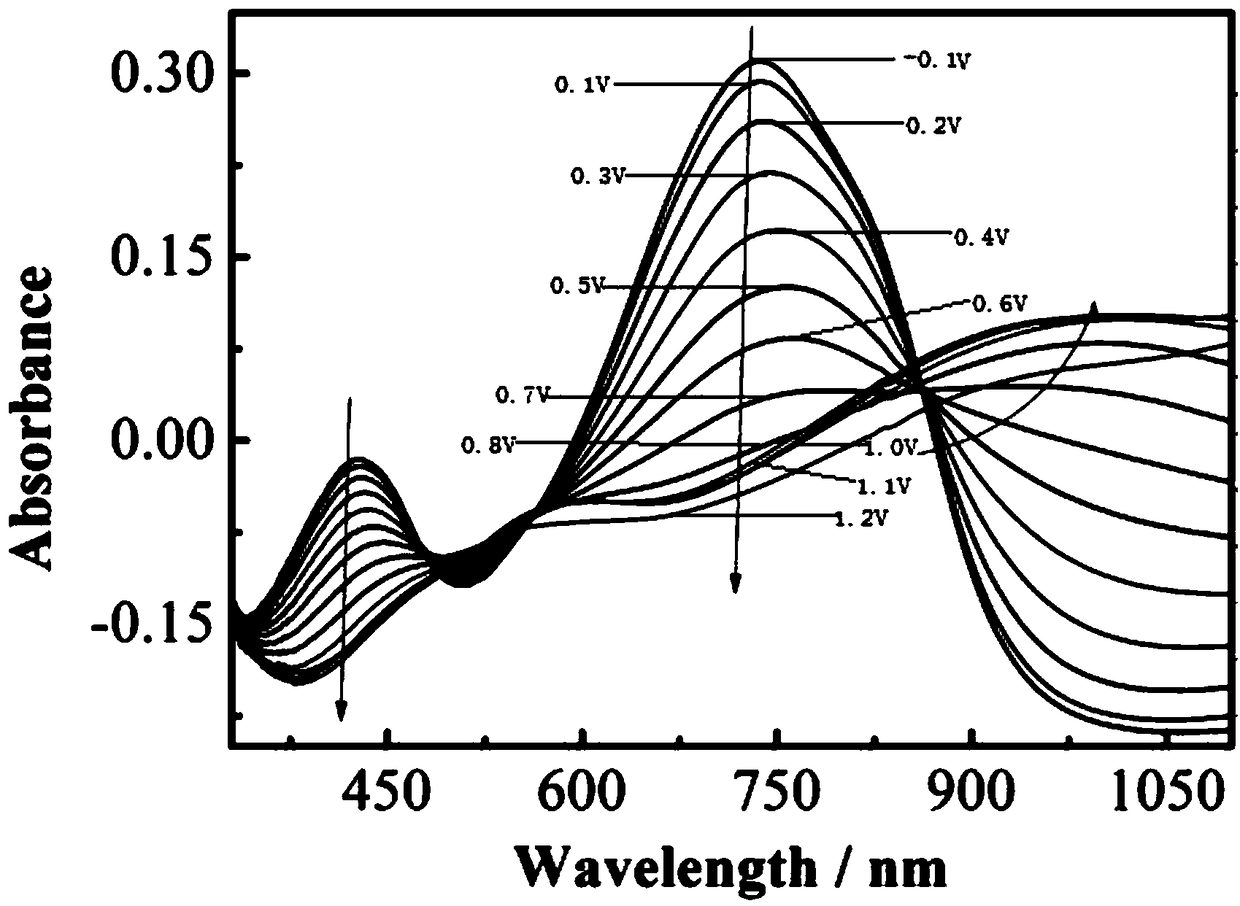

[0086] Embodiment 3: Electrochemical synthesis of P (IDOH-Th) polymer electrochromic material

[0087] (1) Synthesis of IDOH-Th active precursor

[0088]

[0089] Under nitrogen protection conditions, a certain proportion of 6,6'-dibromo-3,3'-dihexylindoledione and 2-tinbutylthiophene were added to a three-necked flask filled with toluene solvent, and the catalyst Pd( PPh 3 ) 2 Cl 2 Under catalysis, it was condensed and refluxed at 110°C for 12 hours; after the reaction, the product was extracted three times with chloroform, dried with a small amount of anhydrous magnesium sulfate for 24 hours, and then the solvent was distilled off under reduced pressure, separated by silica gel chromatography, and purified to obtain a reddish-brown solid product , the yield was 65%. 1 H-NMR (CDCl 3 ): δ9.14(d,J=8.47Hz,2H),7.35–7.33(dd,J 1 =8.4Hz,J 2 =1.6Hz,2H),7.22(s,2H),6.39(s,2H),4.36–4.28(m,8H),3.8–3.7(m,4H),1.65-1.55(m,4H),1.43– 1.24(m,12H),0.98–0.86(m,6H).(eg Figure 9 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com