Electrolytic degreasing device for chip type medium and high power semiconductor element lead frame

A technology for component lead and electrolysis degreasing, applied in electrolysis components, electrolysis process, etc., can solve the problems of poor degreasing effect, inconvenient connection of stamped bare copper plates, and inability to completely remove oil stains, and achieves convenient connection and good degreasing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

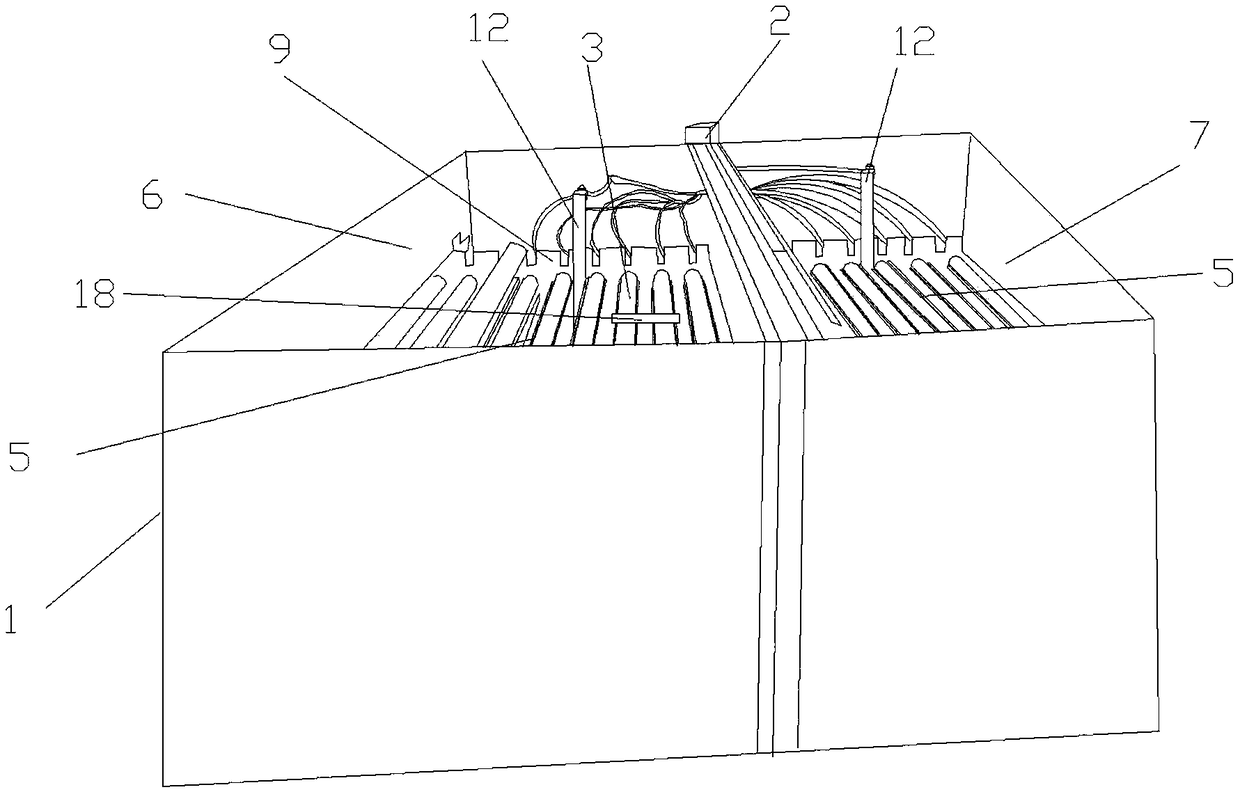

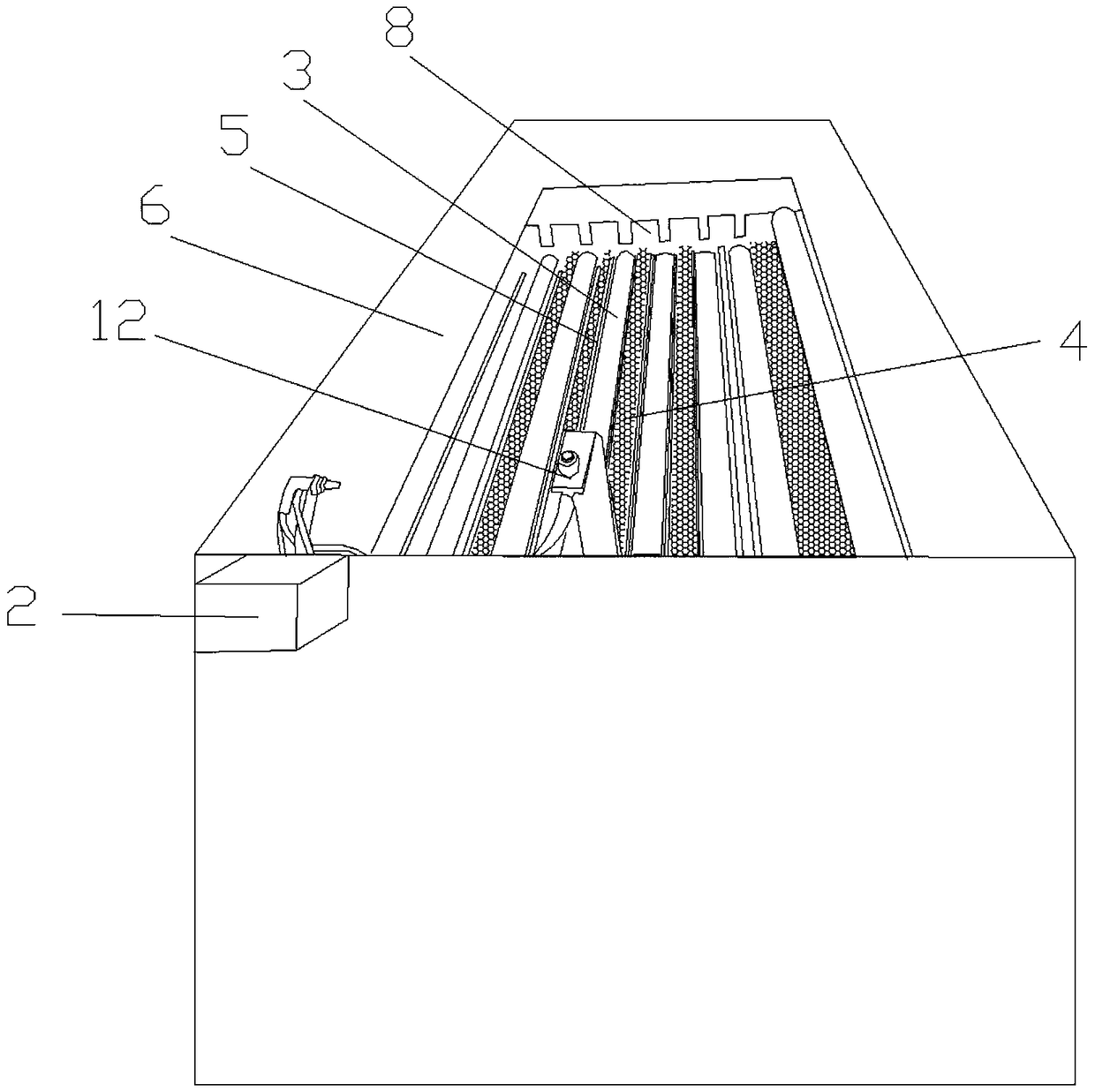

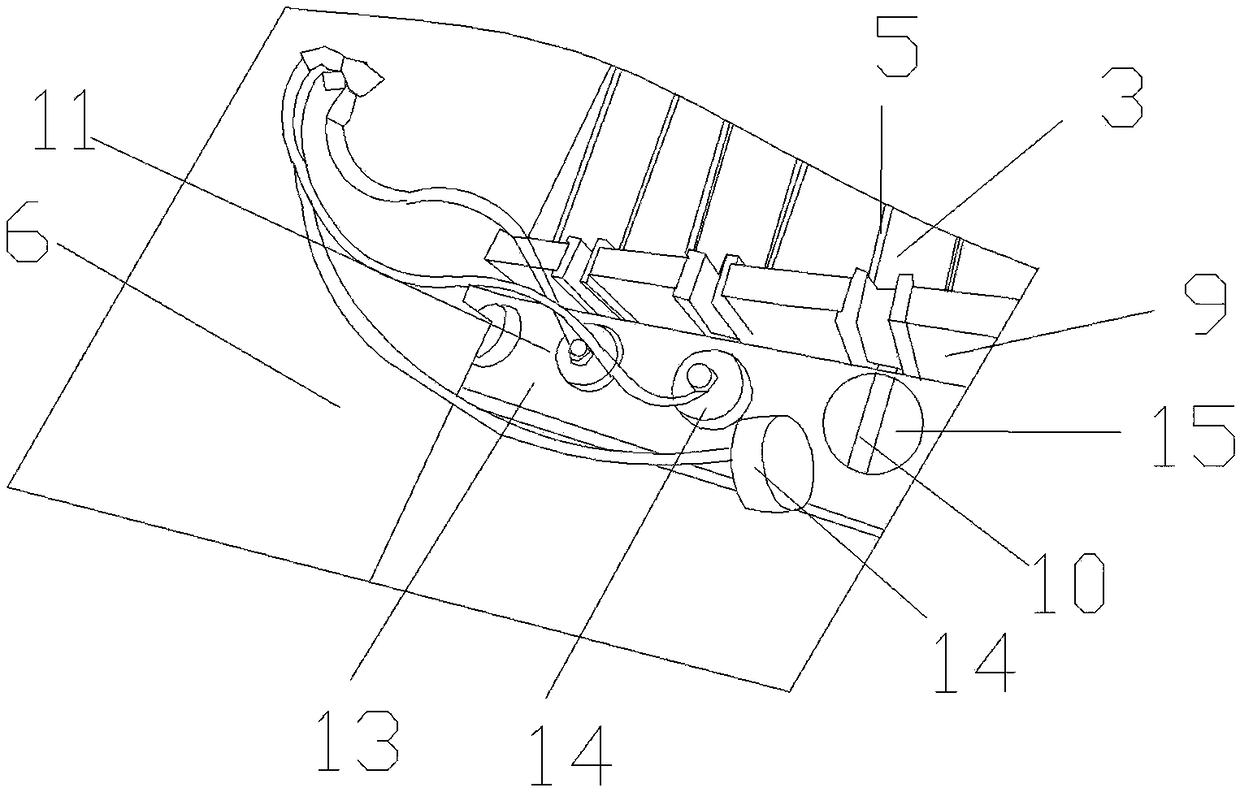

[0020] Such as figure 1 , figure 2 , image 3 As shown, an electrolytic degreasing device for chip-type medium and high-power semiconductor element lead frames includes a degreasing tank 1 and a rectifier 2, and is characterized in that: it also includes a chip type that is arranged side by side on the upper part of the degreasing tank 1 for transmission and electrical connection. A plurality of conductive rollers 3 of the bare copper plate 18 and a conductive plate 4 arranged at the bottom of the oil removal tank 1, the plurality of conductive rollers 3 are electrically connected to the positive or negative pole of the rectifier 2, and the conductive plate 4 is connected to the other of the rectifier 2 Electrode connection, the conductive plate 4 can be mesh, the conductive roller 3 is driven to rotate by the driving device, and the bottom of each conductive roller 3 is provided with an insulating sleeve 5, so that the power line bypasses the bottom of the conductive roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com