Absolute radiometer for solar irradiance calibration and radiometer internal thermal structure

A technology of absolute radiation and solar radiation, applied in the field of remote sensor on-orbit light radiation measurement, can solve the problems of limited processing technology, the contact between the absorption cavity and the thermopile cannot meet the accuracy requirements of the absolute radiometer, and reduce the time constant. , The temperature collection method is designed reasonably and the effect of speeding up the transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

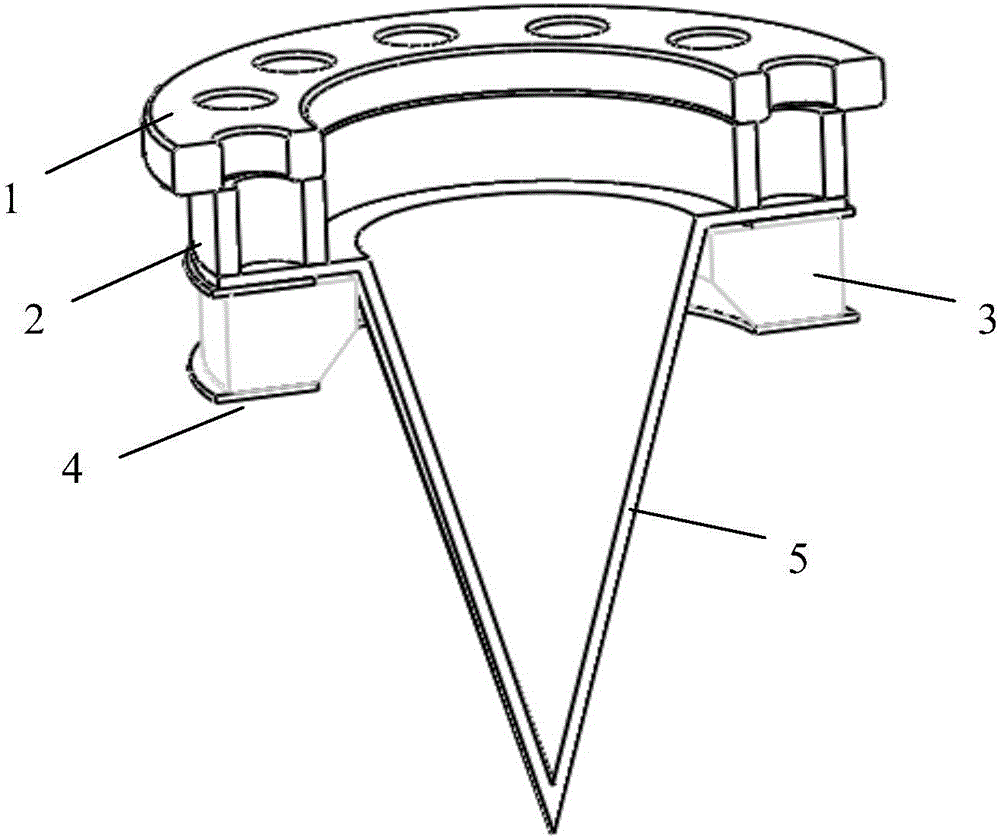

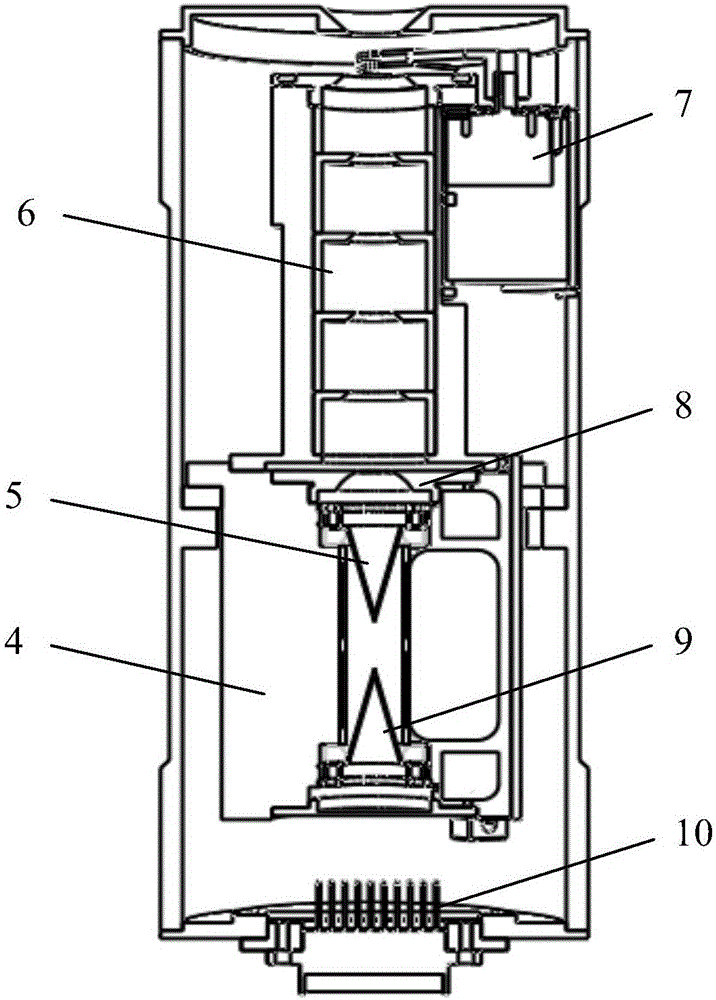

[0014] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this embodiment, the absolute radiometer used for solar irradiance calibration includes: stray light stop 6, motor 7, main stop 8, internal thermal structure of the radiometer, reference cavity 5, and 38-pin plug 10 . The internal thermal structure of the radiometer is as follows: figure 1 Including: pressing plate 1, polyimide gasket 2, thermopile 3, heat sink 4 and absorption chamber 5. The absorption cavity is embedded with a heating wire for electric heating in the light radiation area. In the electric heating stage, the cone cavity is heated by the electric heating wire to achieve the equivalent of light heating. The inside of the absorption cavity 5 is coated with a mirror reflective paint . The reference chamber 9 is connected back to back with the absorption chamber 5 . The heat sink 4 is used to package the reference cavity 9 and the absorption cavity 5; the absorption cavity 5 ado...

specific Embodiment approach 2

[0016] Specific embodiment two, combine figure 1 In this embodiment, the internal thermal structure of the absolute radiometer used for solar irradiance calibration includes a pressing plate 1, a polyimide gasket 2, a thermopile 3, a heat sink 4, and an absorption cavity 5; the absorption cavity 5. A heating wire for electric heating is embedded in the light radiation area. In the electric heating stage, the electric heating wire is used to heat the absorption cavity 5 to achieve the equivalent of light heating. The interior of the absorption cavity 5 is coated with mirror-reflective paint. The reference chamber 9 is connected back to back with the absorption chamber 5 . The heat sink 4 is used to package the reference cavity 9 and the absorption cavity 5 ; the material of the pressing sheet 1 is aluminum, which plays a role of fixing the absorption cavity 5 . The material of the polyimide gasket 2 is polyimide, which plays a role of isolating heat transfer in this direction....

specific Embodiment approach 3

[0018] Specific embodiment three, this embodiment is the method for designing the thermal structure on the absolute radiometer for on-orbit solar irradiance calibration described in specific embodiment two, and this method is realized by the following steps:

[0019] 1. Establishing a 3D model: The engineering software Soliderworks is used for modeling, and the model is established by using the method of matrix rotation. The central angle α of the absorption cavity 5 is 30°, and the inner wall thickness is 0.1 mm. The outer diameter of the visor is determined according to the shape of the thermal link, that is, the radius of the visor should be similar to the radius of the thermopile ring, so that the visor can be better connected with the thermopile and maintain thermal contact. After the two-dimensional sketch is established, rotate along the centerline of the absorption cavity to obtain the required three-dimensional model of the absolute radiometer absorption cavity. Usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com