Production method of simple and high-effective Raman enhanced substrate

A substrate, high-efficiency technology, applied in the field of fluorescent materials, can solve problems such as limited use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

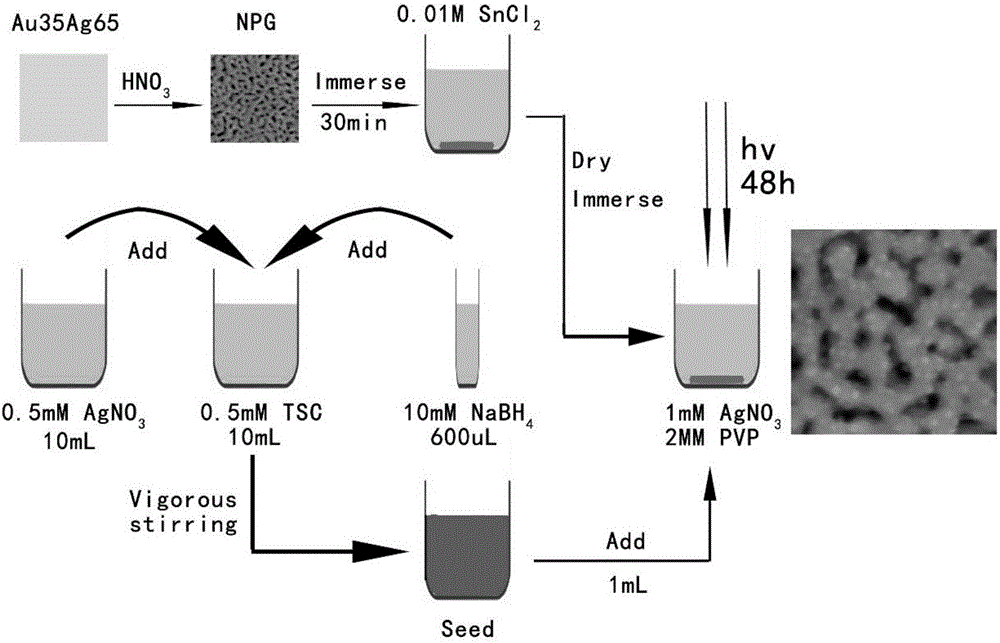

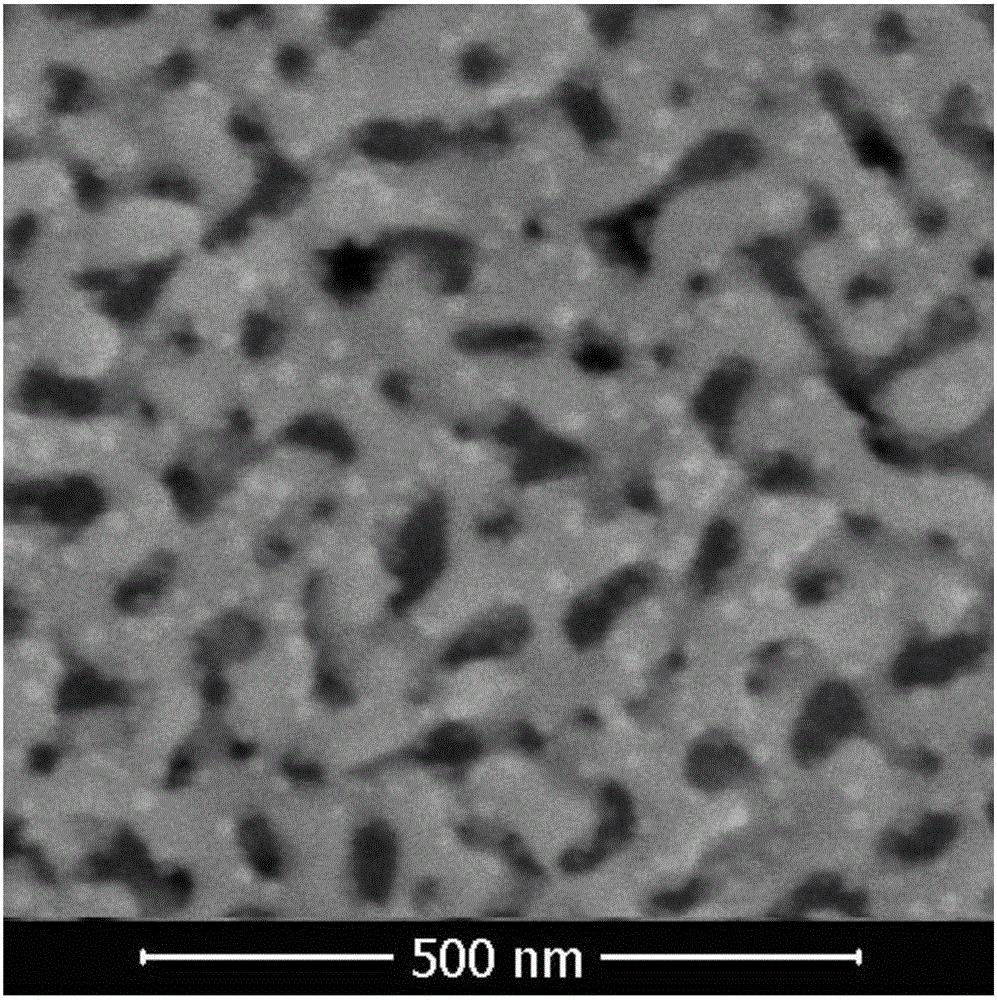

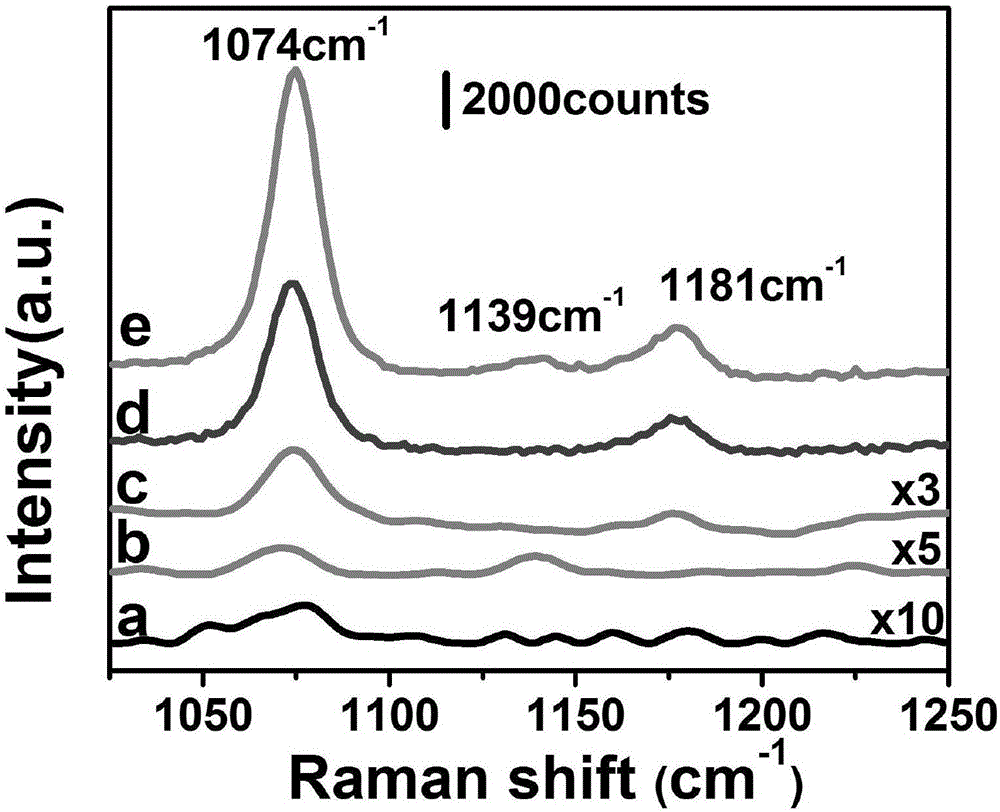

[0027] This embodiment relates to a preparation method of silver nanoparticles modified porous gold surface enhanced Raman substrate, such as figure 1 As shown, the steps are as follows:

[0028] 1. Preparation of porous gold:

[0029] Immerse a 100nm thick gold-silver alloy film in concentrated nitric acid for about 30 minutes to obtain porous gold with a pore size of 29nm. In this gold-silver alloy film, the mass fractions of gold and silver elements are 35% and 65% respectively;

[0030] Take out the porous gold and wash it repeatedly in deionized water to remove the residual chemicals on its surface;

[0031] 2. Preparation of seed crystals:

[0032] 10mL of 0.5mmol / LAgNO 3 Add the aqueous solution to 10mL of 0.5mmol / L sodium citrate aqueous solution, stir vigorously, and quickly add 0.6mL of 10mmol / L NaBH 4 Solution, after stirring, a suspension of silver nanoparticles, i.e. seed crystals, is obtained;

[0033] 3. Making the Ag@NPG substrate:

[0034] The porous gol...

Embodiment 2

[0041] This embodiment relates to a preparation method of silver nanoparticles modified porous gold surface enhanced Raman substrate, such as figure 2 As shown, the steps are as follows:

[0042] 1. Preparation of porous gold:

[0043] Immerse a 90nm thick gold-silver alloy film in concentrated nitric acid for about 5 minutes to obtain porous gold with a pore size of 22nm. In this gold-silver alloy film, the mass fractions of gold and silver elements are 30% and 70% respectively;

[0044] Take out the porous gold and wash it repeatedly in deionized water to remove the residual chemicals on its surface;

[0045] 2. Preparation of seed crystals:

[0046] 9mL of 0.45mmol / LAgNO 3 Add the aqueous solution to 9mL of 0.45mmol / L sodium citrate aqueous solution, stir vigorously, and quickly add 0.5mL of 9mmol / L NaBH 4 Solution, after stirring, a suspension of silver nanoparticles, i.e. seed crystals, is obtained;

[0047] 3. Making the Ag@NPG substrate:

[0048] Put the porous gol...

Embodiment 3

[0052] This embodiment relates to a preparation method of silver nanoparticles modified porous gold surface enhanced Raman substrate, such as figure 2 As shown, the steps are as follows:

[0053] 1. Preparation of porous gold:

[0054] Immerse a 110nm thick gold-silver alloy film in concentrated nitric acid for about 3 hours to obtain porous gold with a pore size of 36nm. In the gold-silver alloy film, the mass fractions of gold and silver elements are 40% and 60% respectively;

[0055] Take out the porous gold and wash it repeatedly in deionized water to remove the residual chemicals on its surface;

[0056] 2. Preparation of seed crystals:

[0057] 11 mL of 0.55 mmol / LAgNO 3 Add the aqueous solution to 11mL of 0.55mmol / L sodium citrate aqueous solution, stir vigorously, and quickly add 0.7mL of 11mmol / L NaBH 4 Solution, after stirring, a suspension of silver nanoparticles, i.e. seed crystals, is obtained;

[0058] 3. Making the Ag@NPG substrate:

[0059] The porous go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com