Steel rail crack detection method based on multiple acoustic emission event probabilities

A technology of event probability and crack detection, which is applied in the direction of material analysis, measuring devices, and processing detection response signals using acoustic wave emission technology, which can solve problems not considered by CNN

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

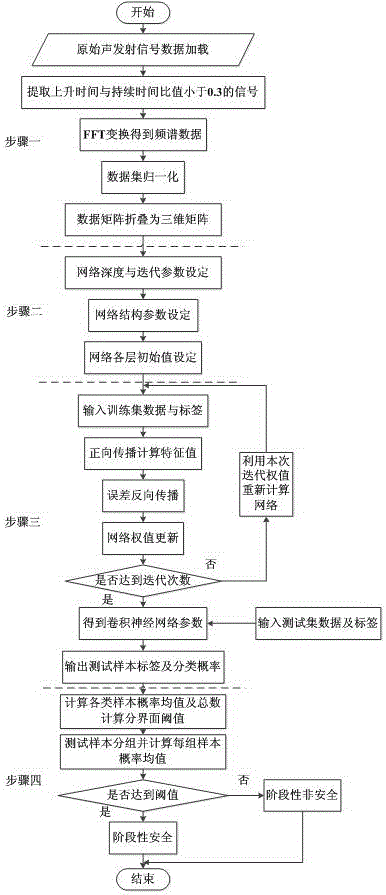

Method used

Image

Examples

specific Embodiment approach

[0039] Below in conjunction with embodiment and accompanying drawing illustrate the specific implementation of the present invention: verify that the sample library of the present invention comes from the acoustic emission time-domain signal library that obtains in the steel plate tensile fracture experiment, and the signal library itself is collected and stored according to the chronological order in the experiment, and the experimental sampling The frequency is 5 MHz, and each signal includes 2048 sampling points. Therefore, the damage stage of the signal library should be divided first according to the stress-strain curve of the rail material, which is divided into two categories: safe and unsafe, and the corresponding labels are recorded as 0 and 1. Create a corresponding label database, and remove the signals that are in the transition stage and the category affiliation is not clear enough, and then normalize the data to facilitate subsequent operations.

[0040] Execute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com