Transformer three-layer insulated wire hot-melt crimping line high equipment and hot-melt crimping line high technology

A three-layer insulation and transformer technology, applied in the field of transformer manufacturing, can solve the problems of large differences and high defect rate, and achieve the effect of improving efficiency, saving manpower and material resources, and peeling cleanly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

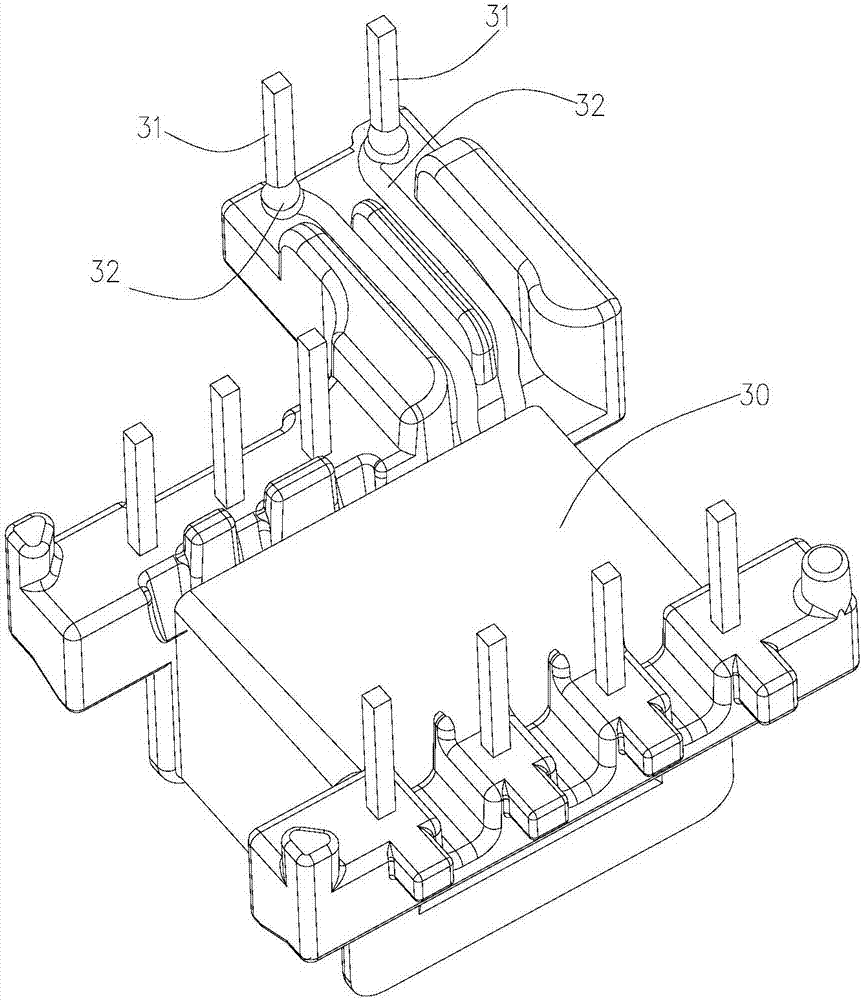

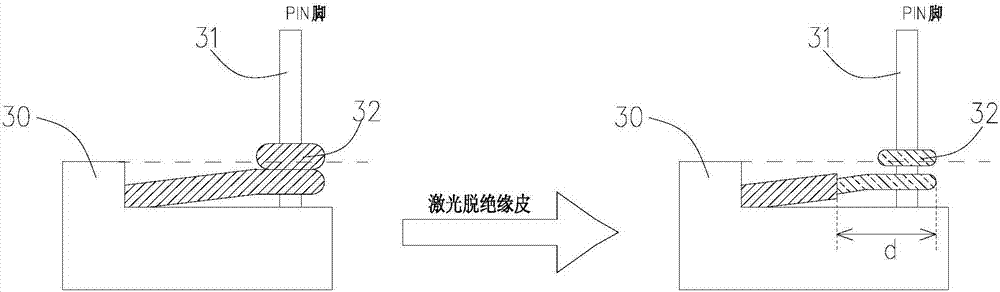

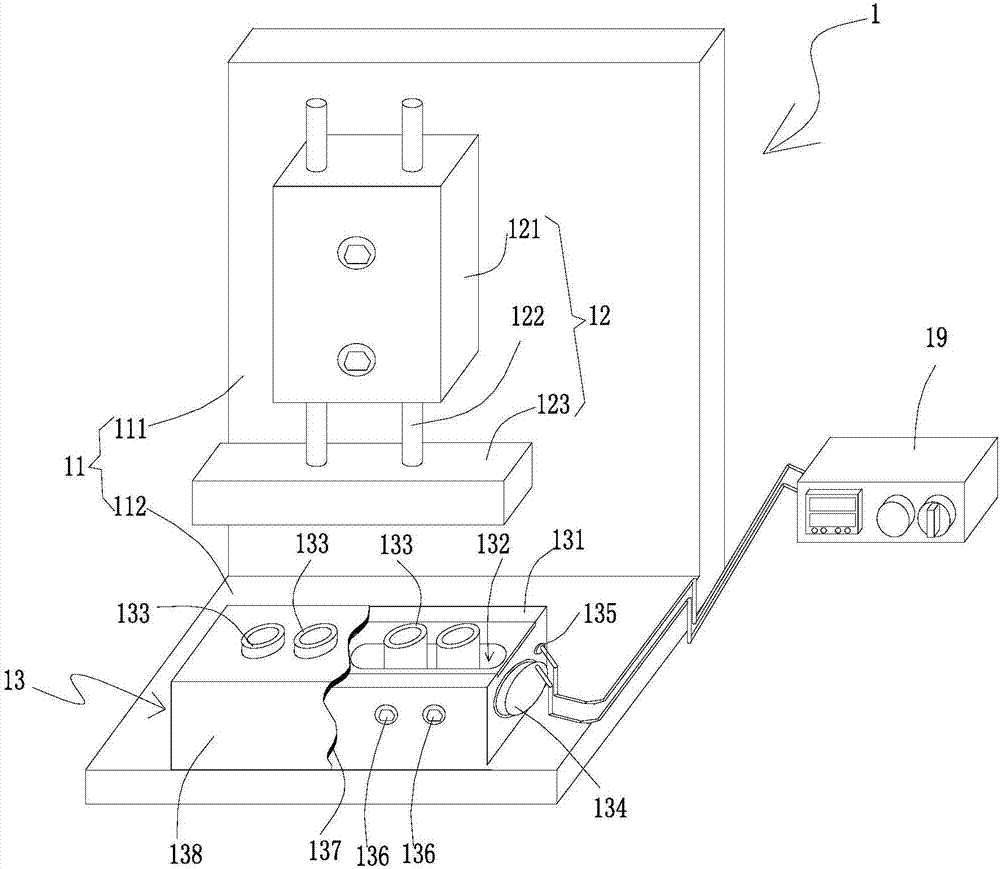

[0029] Such as Figure 3 ~ Figure 6 As shown, a transformer three-layer insulated wire hot-melt crimping equipment includes a hot-melt crimping module 1, a manipulator 2, and a PLC control module that coordinates the hot-melt crimping module 1 and the manipulator 2 to work together (not shown in the figure) show). The manipulator 2 places the transformer to be processed from the feeding place 50 on the hot-melt pressing line height module 1 to carry out the heat-melting pressing line height of the three-layer insulated wire on the transformer PIN pin 31. After the process is completed, it will The processed transformer is placed at the blanking place 60 .

[0030] The hot-melt pressure line height module 1 includes an L-shaped fixing frame 11 , the fixing frame 11 is composed of a bottom plate 112 and a vertical plate 111 , and a block-shaped hot-melt table 13 is arranged on the bottom plate 112 . Preferably, the hot-melt table 13 is in the shape of a cuboid, including the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com