Dynamic voltage restorer

A dynamic voltage recovery and controller technology, applied in the direction of AC network voltage adjustment, etc., can solve the problems of poor anti-shake power of inverter, poor anti-shake power of contactor, tripping, etc., to improve safety and high authority requirements , Guarantee the effect of load working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

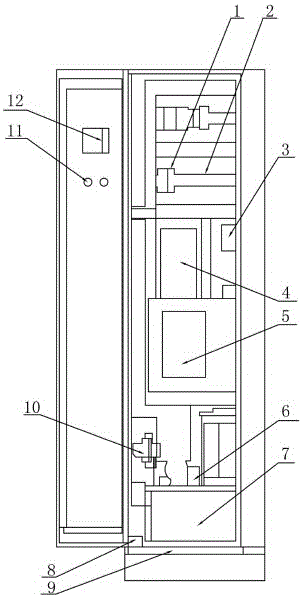

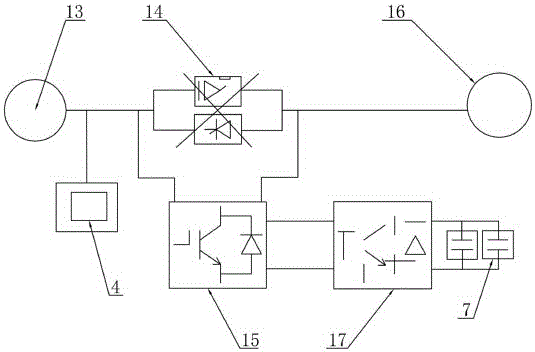

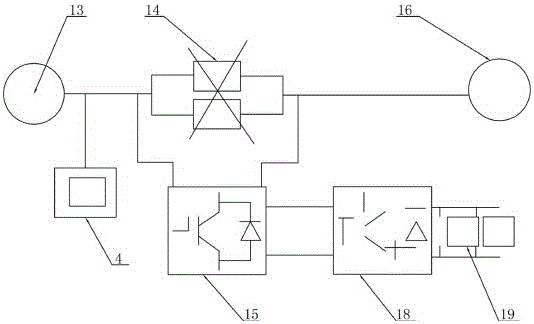

[0017] see figure 1 , figure 2 and image 3 As shown, the present invention provides a dynamic voltage restorer, including a secondary circuit control switch 1, a signal collector 2, a switching power supply 3, a controller 4, a power module 5, a filter circuit 6, a supercapacitor 7, and a ground bus Row 8, cabinet body 9, incoming line circuit 10, operation button 11, LCD touch screen 12, power system 13, anti-parallel thyristor 14, H-bridge inverter 15, load 16, DC chopper boost circuit 17, Electronic switch 18 and release resistor 19, cabinet body 9 is provided with secondary circuit control switch 1, signal collector 2, switching power supply 3, controller 4, power module 5, filter circuit 6, super capacitor 7, grounding bus bar 8 and the incoming line circuit 10, the cabinet body 9 is provided with a cabinet door, the cabinet door is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com