Olefin copolymer and preparation method and application thereof

An olefin copolymer and copolymerization technology, applied in the field of olefin copolymer, can solve the problems of large rolling resistance of rubber, and achieve the effect of reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

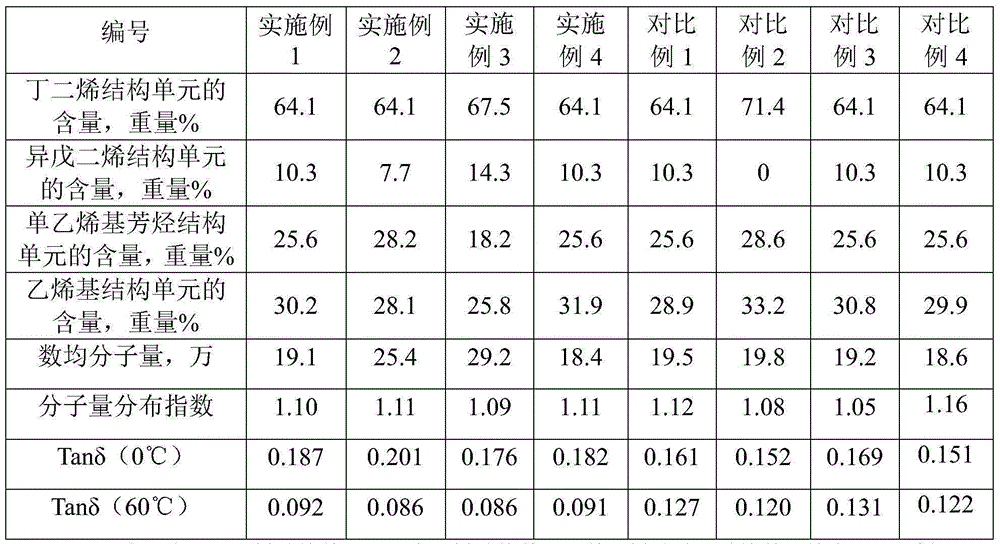

Examples

preparation example Construction

[0022] The preparation method of olefin copolymer provided by the invention comprises the following steps:

[0023] (1) Under an inert gas environment, the tin-containing organic dilithium initiator and a conjugated diene monomer and a monovinylarene monomer are carried out in an inert solvent for the first polymerization reaction;

[0024] (2) When the total monomer conversion rate of the conjugated diene monomer and monovinylarene monomer reaches 70%-85%, the first polymerization reaction product and isoprene monomer are subjected to the second polymerization reaction.

[0025] It can be seen from the principle of polymerization that the olefin copolymer prepared by the above method contains a copolymerization structural unit 1 and a copolymerization structural unit 2, and the copolymerization structural unit 2 is distributed at both ends of the molecular chain of the olefin copolymer, and the copolymerization structural unit 1 is a segment formed by a monovinylarene struct...

Embodiment approach

[0040] According to the present invention, the preparation method of the olefin polymer can be implemented by various existing conventional methods. According to a specific embodiment of the present invention, the preparation method of the olefin polymer may include: replacing the polymerization reactor with high-purity nitrogen for 2-3 times, adding an organic solvent to the polymerization reactor under the protection of high-purity nitrogen, Then add conjugated diolefin monomer, monovinylarene monomer and structure regulator to the polymerization reactor, raise the temperature of the polymerization reaction system to 30-150°C, and then add tin-containing organic dilithium initiator, when When the conversion rate of the total monomers in the polymerization reactor reaches 70%-85%, add isoprene into the polymerization reactor, and after the reaction is complete, add a terminator to carry out the termination reaction.

[0041] According to the present invention, preferably, aft...

preparation example 1

[0052] This preparation example is used to illustrate the tin-containing organic dilithium initiator provided by the present invention and its preparation method.

[0053] In a 250mL three-necked flask, pump and fill nitrogen, add dilithium compound Li(CH 2 ) 4 Li ether solution 20mL, dropwise added (CH 3 (CH 2 ) 7 ) 2 SnCl 2 15 mL of tetrahydrofuran solution, in which the dilithium compound Li(CH 2 ) 4 Li and (CH 3 (CH 2 ) 7 ) 2 SnCl 2 The molar ratio is 2:1, and the reaction is stopped after reacting at 10° C. for 2 hours to obtain a tin-containing organic dilithium initiator. The concentration of active lithium measured by double titration was 0.512 mol / L, and the functionality was 1.88.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com