Double-layer self-breathing thermal-insulation squat silo

A self-breathing, double-layer technology, applied in the field of shallow round bins for grain storage, can solve the problems of large power loss and cost increase, and achieve the effects of simplifying the structure, reducing heat, and isolating heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

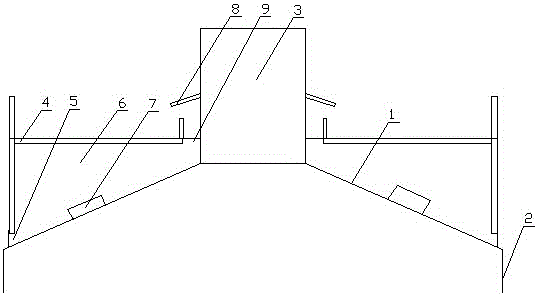

[0046] Such as figure 1 As shown: this embodiment provides a double-layer self-breathing and heat-insulating shallow circular warehouse, including a warehouse wall 2 and a conical warehouse roof 1, the center of the conical warehouse roof 1 is a closed upper corridor 3, and the conical warehouse roof 1 A top cover 4 is arranged above the warehouse roof 1, and an air interlayer 6 is formed between the roof 4 and the conical warehouse roof 1, and an air layer 6 is provided between the roof 4 and the closed upper corridor 3. An air outlet 9 connected to the interlayer 6, an air inlet 5 is provided between the top cover 4 and the edge of the conical roof 1, and a rain-shielding mechanism 8 is provided at the air outlet 9.

[0047] There is an oblique air space between the top cover and the conical silo roof. The lower end of the air space is the air inlet, and the upper end is the air exhaust port. Using the chimney effect, the hot air in the air space can be effectively removed u...

Embodiment 2

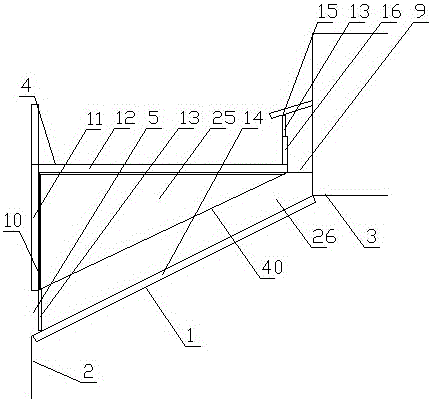

[0050] Such as figure 1 and figure 2 Shown: its difference with embodiment one is:

[0051] The top cover 4 includes a circle of L-shaped brackets 10 arranged on the conical silo roof 1, one end of the L-shaped bracket 10 is connected to the side wall of the closed upper corridor 3, and the L-shaped bracket 10 The other end is connected with the edge of the conical silo roof 1, the L-shaped bracket 10 side is provided with a coaming plate 11, the upper part of the L-shaped bracket 10 is provided with a top plate 12, and the lower side of the coaming plate 11 is connected with the conical Between the edges of the warehouse roof 1 is the air inlet 5 , and between the inner side of the top plate 12 and the side wall of the closed upper corridor 3 is the air exhaust port 9 .

[0052] The top cover is a mechanism added on the roof of the warehouse, so there are great requirements for the firmness of the top cover. The support part of the roof adopts several L-shaped brackets, a...

Embodiment 3

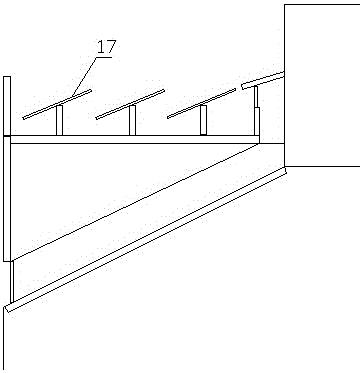

[0058] Such as image 3 and Figure 4 Shown: its difference with embodiment two is:

[0059] A solar panel 17 is arranged above the top cover 4 . The solar panels installed on the top cover can convert solar energy into electrical energy, which can not only provide electrical energy for the electrical equipment in the shallow circular warehouse, but also reduce the heat converted from solar energy, and indirectly reduce the heating effect of the solar radiation on the shallow circular warehouse .

[0060] Or the surrounding board 11 and the roof board 12 adopt solar panels. Solar panels can also directly replace the coaming and roof panels on the top cover, which can not only absorb and convert solar energy, but also play the role of enclosing the city's air space. Compared with installing solar panels on the top cover, it saves coaming and The material of the top plate simplifies the structure of the top cover.

[0061] The solar panel 17 is respectively connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com