Cooking method

A pot body and rotation axis technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of difficult heat conduction, unsatisfactory, low heating and cooking efficiency, etc., to increase the heat transfer area and reduce the heat transfer Distance, effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

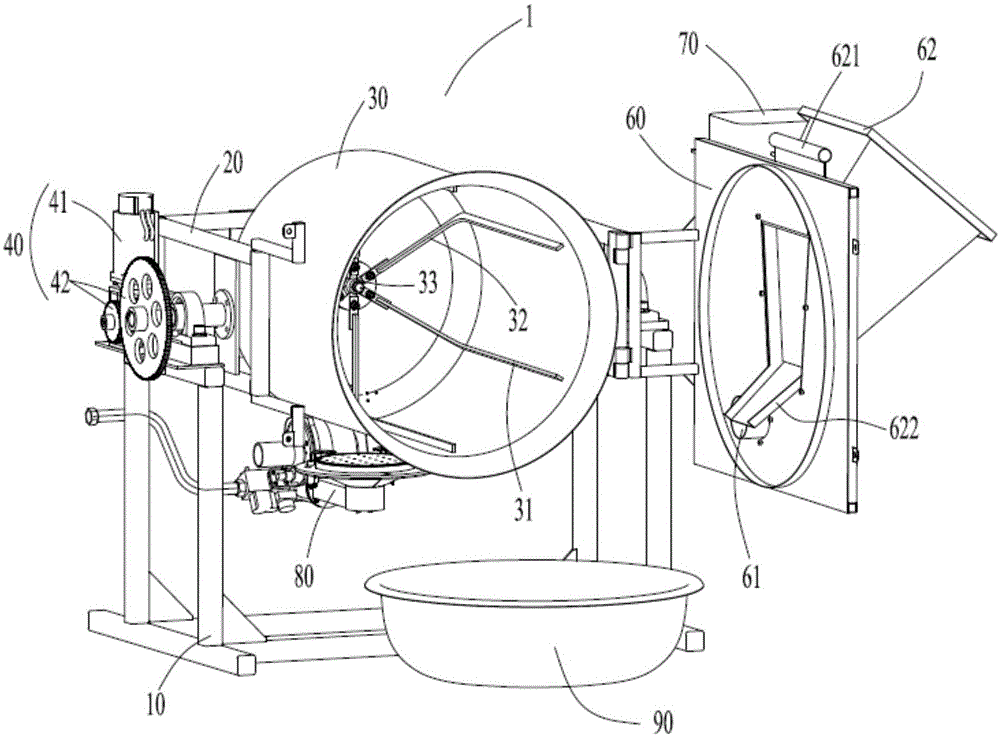

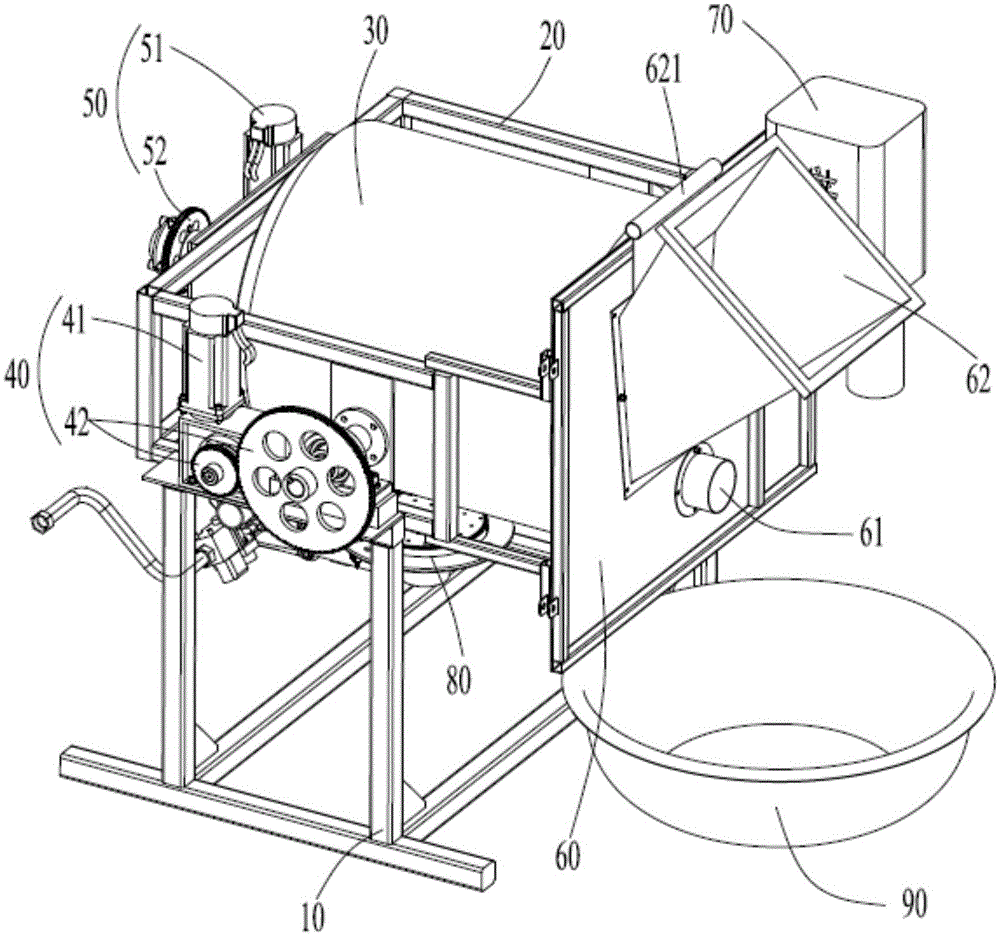

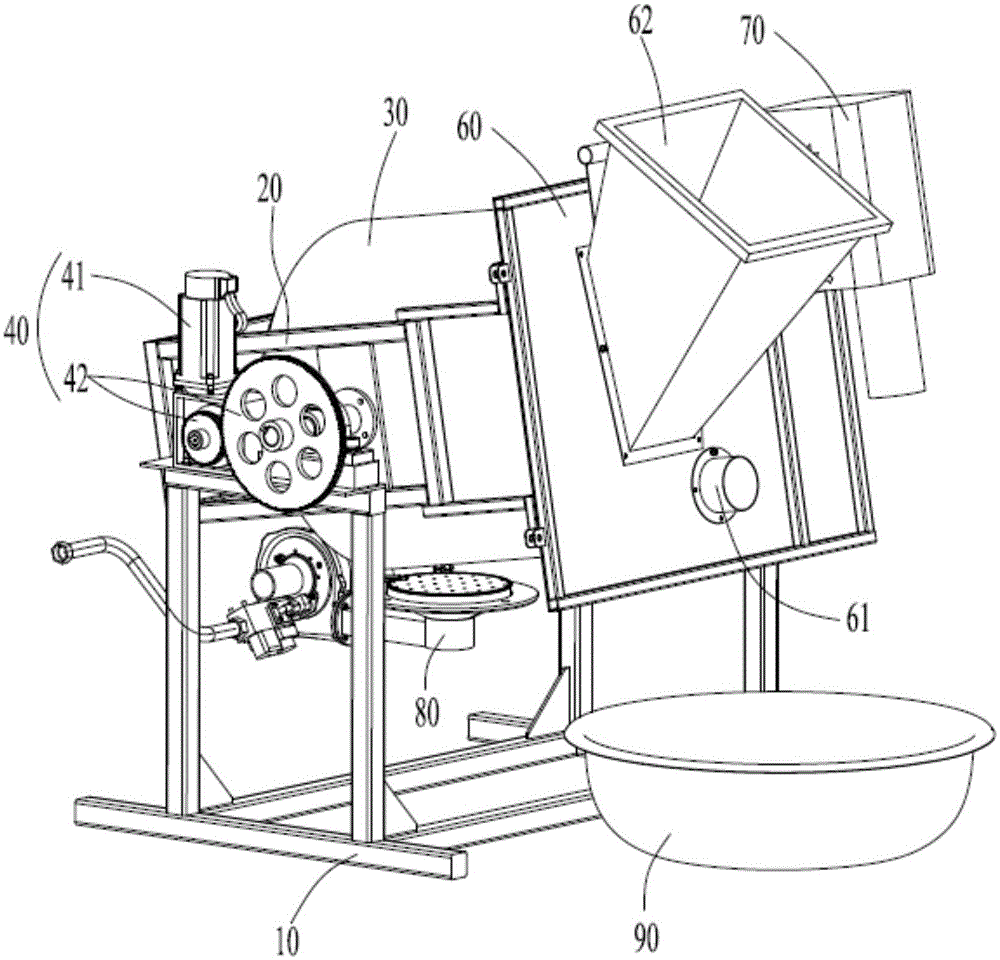

[0061] Such as Figure 1-2 As shown, the cooking system 1 in this embodiment includes a controller (not shown in the figure), a main body support 10, a pot body support 20 rotatably arranged on the main body support 10, and a pot body support 20 rotatably arranged on the pot body support 20. The pot body 30 on the top, the angle adjustment device 40 arranged on the main body support 20, the rotary drive device 50 arranged on the pot body support 20, the pot cover 60 which can be opened and closed on the pot body support 20, the pot cover 60 arranged on the pot The hot air heating device 70 on the cover 60 , the gas heating device 80 which is arranged under the pot body 30 and heats the pot body 30 , and the vegetable output device 90 .

[0062] The pot body 30 is a barrel-shaped pot body with a circular inner circumference in cross section, its main body has approximately the same inner diameter, a pot mouth is formed at the front end, and a hollow pot body extending on the ro...

Embodiment 2

[0074] Such as Figure 6 As shown, in this embodiment, the pot body 130 is rotatably disposed on the pot body support 120 , and a conical feature 131 inclined toward the rotation axis of the pot body 130 is formed at one end of the pot body near the mouth of the pot body. The rotating shaft of the pot body is connected with the gear transmission mechanism 152, and the motor 151 drives the pot body 130 to rotate around its rotation axis through the gear transmission mechanism 52.

[0075] see Figure 6 and 7 , the inner wall of the pot body 130 is provided with six ribs 132 distributed in an annular array, and the ribs 132 extend continuously between two longitudinal ends of the pot body 130 along the rotation axis of the pot body 130 . Inside the pot body 130 are disposed six scraping pieces 134 that can move linearly back and forth along the rotation axis of the pot body 130 , and each scraping piece 134 is respectively arranged between adjacent ribs 132 . The scraper 134 ...

Embodiment 3

[0082] Such as Figure 8 As shown, in this embodiment, the pot body 230 is provided with a scraper 231 that can expand and contract along its radial direction, and the scraper 231 is between the two longitudinal ends of the pot body 230 along the direction of the rotation axis of the pot body 230 Continuously extending, one end away from the mouth of the pot is fixedly connected with the sliding rod 232 . The sliding rod 232 is slidably installed on the fixing base 233 , and the fixing base 233 is fixedly installed in the pot body 230 . The longitudinal end of the sliding rod 232 abuts against the cam 243, and the cam 243 is connected with the gear transmission mechanism 242 via the rotating shaft passing through the rotating shaft of the pot body. 230 radial telescoping. In the extended state, the scraping member 231 is closely adjacent to the inner wall of the pot body 230 at approximately the highest point of the rotation track of the pot body, and in the retracted state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com