Dental diamond bur

A diamond and bur technology, applied in the field of dental instruments, can solve the problems of patients' discomfort and pain, easy damage to dental nerves, prolong the treatment time, etc., and achieve the effect of reducing discomfort and pain, reducing slipping, and shortening the treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

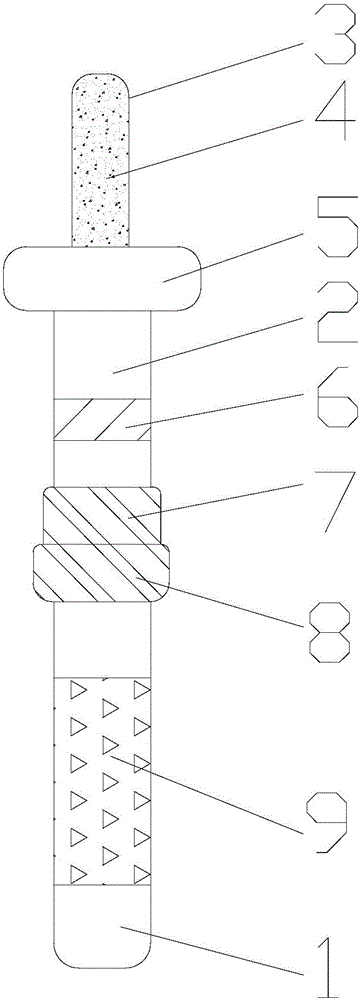

Embodiment 1

[0019] as attached figure 1 As shown, a dental diamond bur includes a bur handle 1 , a bur neck 2 and a working needle tip 3 . The bur handle 1 is provided with an anti-slip pattern 9, which is more stable to hold and reduces slipping. The shape of the working needle point 3 is round and cylindrical, and the surface of the working needle point 3 is plated with a layer of diamond abrasive 4 by electroplating. The working needle point 3 and the bur neck 2 are welded and fixed, and a protruding baffle 5 is fixed at the joint between the two. The plane of the protruding baffle 5 is perpendicular to the central axis of the working needle point 3, and the diameter of the protruding baffle 5 is larger than the working needle point. The maximum diameter of 3, the material of protruding baffle 5 is transparent medical silica gel. The bur neck 2 is provided with an internal thread 7, the bur handle 1 is provided with an external thread 8, the bur neck 2 and the bur shank 1 are threade...

Embodiment 2

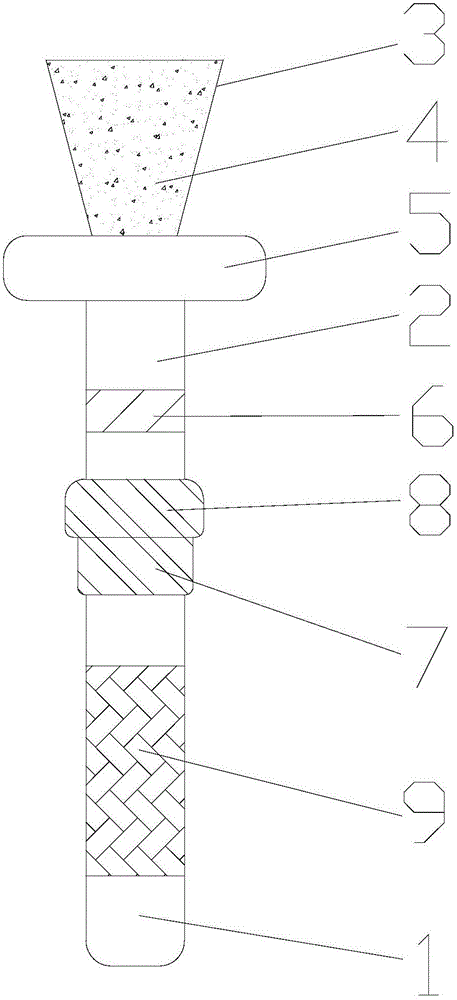

[0025] as attached figure 2 As shown, a dental diamond bur includes a bur handle 1 , a bur neck 2 and a working needle tip 3 . The bur handle 1 is provided with an anti-slip pattern 9, which is more stable to hold and reduces slipping. The shape of the working needle point 3 is an inverted cone, and the surface of the working needle point 3 is plated with a layer of diamond abrasive 4 by electroplating. The working needle point 3 and the bur neck 2 are welded and fixed, and a protruding baffle 5 is fixed at the joint between the two. The plane of the protruding baffle 5 is perpendicular to the central axis of the working needle point 3, and the diameter of the protruding baffle 5 is larger than the working needle point. The maximum diameter of 3, the material of protruding baffle 5 is transparent medical silica gel. The bur neck 2 is provided with an external thread 8, the bur handle is provided with an internal thread 7, the bur neck 2 is threadedly connected with the bur ...

Embodiment 3

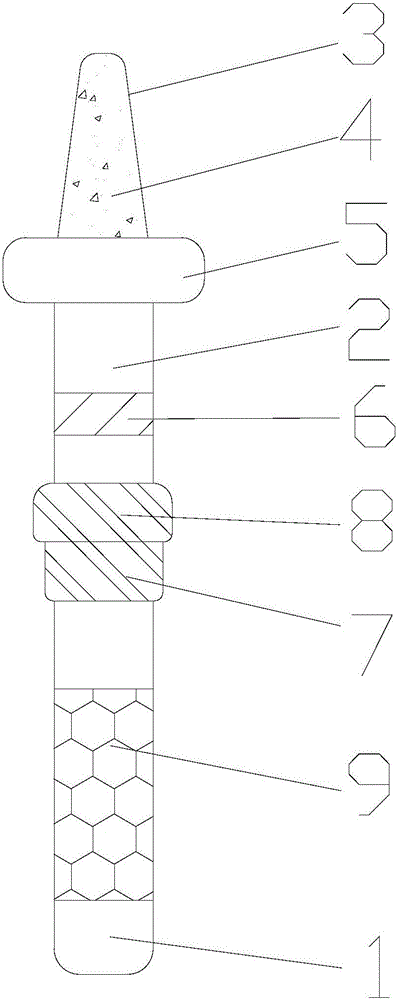

[0032] as attached image 3 As shown, a dental diamond bur includes a bur handle 1 , a bur neck 2 and a working needle tip 3 . The bur handle 1 is provided with an anti-slip pattern 9, which is more stable to hold and reduces slipping. The shape of the working needle point 3 is conical, and the surface of the working needle point 3 is plated with a layer of diamond abrasive 4 by electroplating. The working needle point 3 and the bur neck 2 are welded and fixed, and a protruding baffle 5 is fixed at the joint between the two. The plane of the protruding baffle 5 is perpendicular to the central axis of the working needle point 3, and the diameter of the protruding baffle 5 is larger than the working needle point. The maximum diameter of 3, the material of protruding baffle 5 is transparent medical silica gel. The bur neck 2 is provided with an external thread 8, the bur handle 1 is provided with an internal thread 7, the bur neck 2 is threadedly connected with the bur shank 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com