A method for processing fine powder and fine powder particles of Chinese herbal medicine

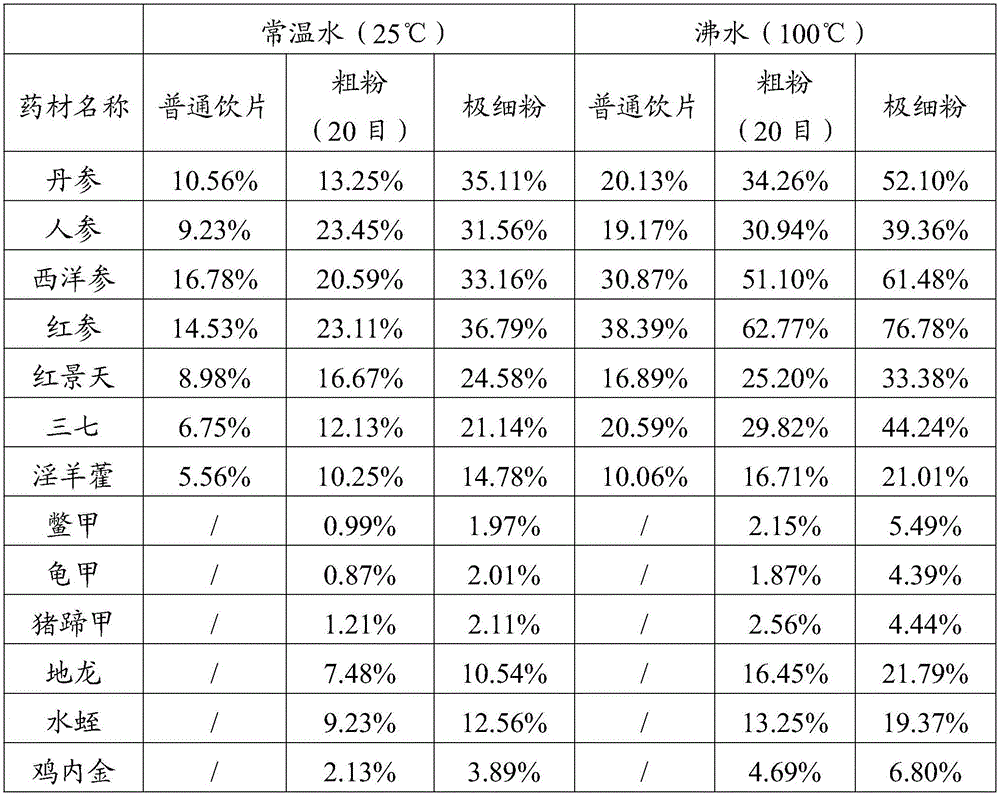

A processing method and ultra-fine powder technology, which is applied in the fields of pharmaceutical formula, powder transportation, plant raw materials, etc., can solve the problems of inconvenient use and carrying, difficult release of active ingredients, and irregular processing and processing, so as to improve the utilization rate of medicinal materials, The effect of improving the dissolution rate and avoiding the troublesome decoction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An embodiment of the processing method of the ultra-fine powder of Chinese medicinal materials according to the present invention, the Chinese medicinal material described in this embodiment is Danshen, and the ultra-fine powder of Danshen is prepared by the following method:

[0036] (1) Medicinal material processing: select and remove impurities and foreign matter mixed in the salvia miltiorrhiza, wash with water, cut into small sections with a medicine cutter, and then quickly clean it again to obtain clean medicinal materials;

[0037] (2), drying: put the clean medicinal material obtained in step (1), that is, the net medicinal material after Salvia miltiorrhiza miltiorrhiza, into an electric constant temperature drying oven, and the temperature is set at 70°C. After drying, put it to room temperature, and put it into adhesive tape to prevent pollution.

[0038] (3), coarse pulverization: the dry clean medical material of step (2) gained is the salvia miltiorrhiza m...

Embodiment 2

[0043] An embodiment of the processing method of the ultrafine powder of Chinese medicinal materials described in the present invention, the Chinese medicinal material described in this embodiment is turtle shell, and the ultrafine powder of turtle shell is prepared by the following method:

[0044] (1) Medicinal material processing: select and remove the impurities, foreign matter and residual meat mixed in the turtle shell, break the turtle shell into small pieces with a knife or hammer, and obtain the clean medicinal material;

[0045] (2), drying: the clean medicinal material that step (1) gained is the turtle carapace fragment and is packed into sealing tape, prevents pollution, is placed in desiccator and preserves, obtains the dry clean medicinal material;

[0046] (3), coarse pulverization: the dry clean medicinal material of step (2) gained is the dry and clean turtle shell fragments, pulverizes with the universal pulverizer of 20 mesh sieves, obtains coarse pulverizat...

Embodiment 3

[0051] An embodiment of the processing method of the fine powder of Chinese medicinal materials described in the present invention, the Chinese medicinal material described in this embodiment is tortoise shell, and the extremely fine powder of tortoise shell is prepared by the following method:

[0052] (1), processing of medicinal materials: boil and soak in clear water for processing, select and remove foreign matter and residual meat mixed therein, to obtain pure medicinal materials;

[0053] (2), drying: the net medicinal material of step (1) gained, i.e. the tortoise shell, is smashed to make the medicinal material into irregular small fragments, and the fragments are packed into sealing tape to prevent pollution, and obtain the dry net medicinal material;

[0054] (3), coarse pulverization: the dried net medical material of step (2) gained is the tortoise shell fragment of dry cleanness, pulverizes with the universal pulverizer of 20 mesh sieves, obtains coarse pulverizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com