Economical and efficient casting workshop dust removal system

A foundry workshop and dust removal system technology, which is applied in the direction of dust removal, dispersion particle separation, chemical instruments and methods, etc., can solve the problems of high cost, achieve small footprint, reduce investment, and achieve good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

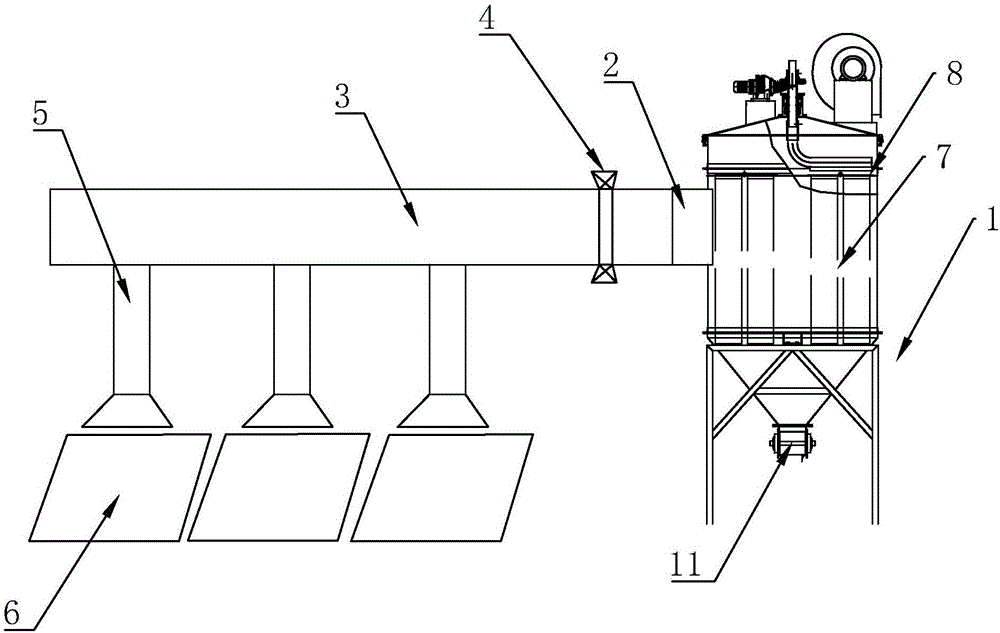

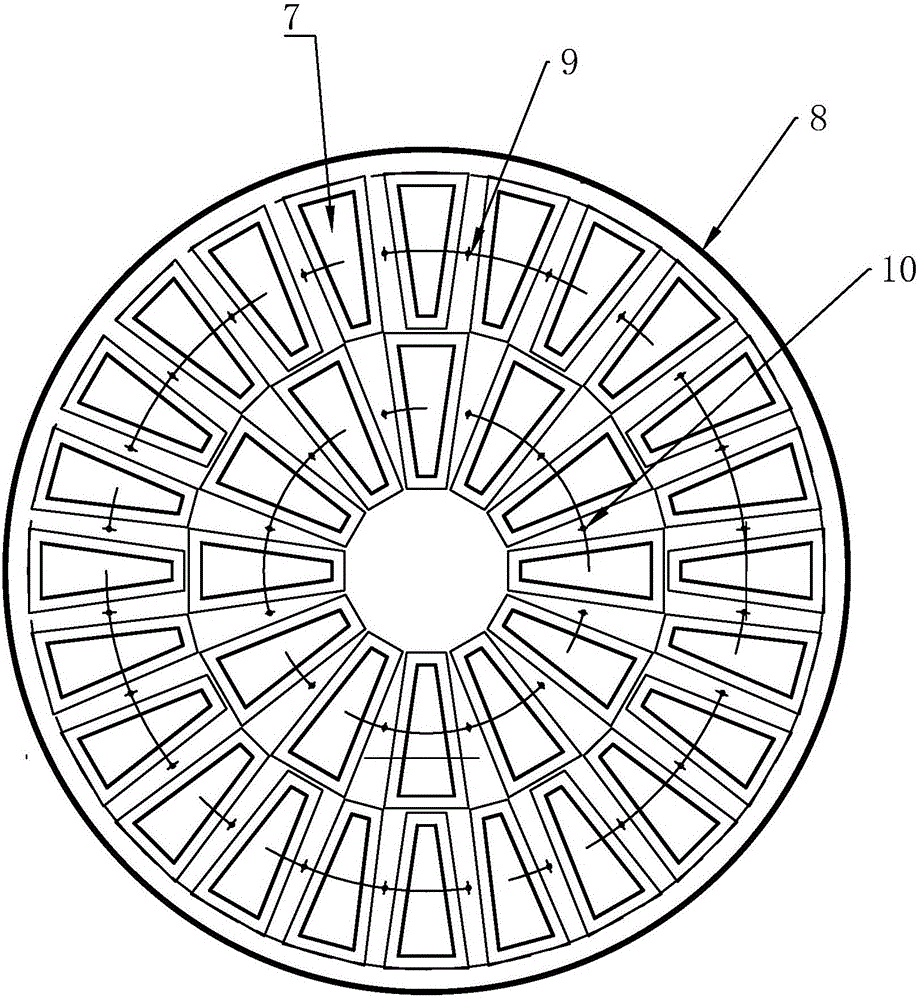

[0015] like figure 1 As shown, a cost-effective dust removal system for a foundry includes a bag filter 1, the bag filter 1 includes an air inlet pipe 2, and the air inlet pipe 2 is connected to a bypass ventilation pipe 3, and the air inlet pipe 2 and the bypass ventilation pipe 3 is provided with a switching valve 4, the bypass ventilation pipe 3 is provided with several additional ventilation pipes 5, each of the additional ventilation pipes 5 is located above the grinding area 6, the The bag filter 1 includes a bag holder 8 on which a plurality of bags 7 are arranged, and each bag 7 has a trapezoidal cross section.

[0016] An economical and efficient dust removal system for foundry of the present invention integrates the dust removal device in the grinding area 6 into the bag dust collector 1 by utilizing the bag dust collector 1 in the foundry, thus reducing equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com